Preparation technology of ZnSnOx ceramic target and method for preparing ZnSnOx coated film by using same

A zinc tin oxide and preparation process technology, applied in metal material coating process, sputtering plating, ion implantation plating and other directions, can solve the problems of poor sputtering process stability, negative impact on physical and chemical properties, Ag layer oxidation, etc. To achieve the effect of strong sputtering voltage stability, easy process and strong film adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

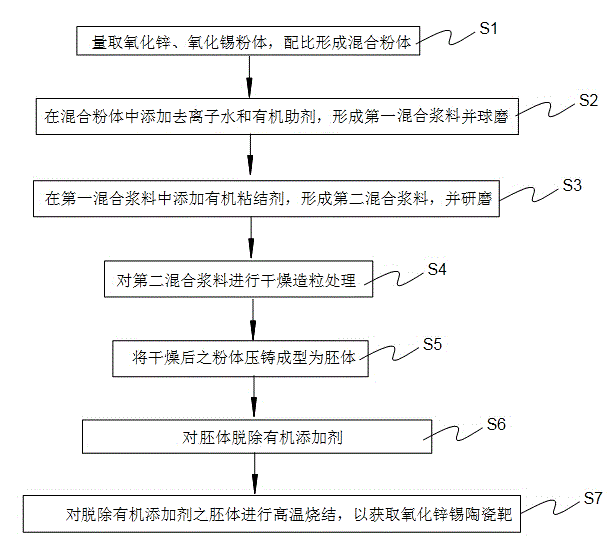

Method used

Image

Examples

Embodiment 1

[0038] The zinc-tin oxide thin film prepared by using the zinc-tin oxide ceramic target of the present invention can be applied in low-radiation coating products of Sanyinke steel. The specific film structure is:

[0039] Glass / Si 3 N 4 / AZO / NiCr / Ag / NiCr / AZO / ZnSnOx / AZO / NiCr / Ag / NiCr / AZO / ZnSnOx / AZO /

[0040] NiCr / Ag / NiCr / AZO / Si 3 N 4 .

Embodiment 2

[0042] The zinc-tin oxide thin film prepared by using the zinc-tin oxide ceramic target of the present invention can be applied to double-silver steel low-radiation coating products. The specific film structure is:

[0043] Glass / Si 3 N 4 / AZO / NiCr / Ag / NiCr / AZO / ZnSnOx / AZO / NiCr / Ag / NiCr / AZO / Si 3 N 4 .

[0044]In summary, when the zinc-tin oxide ceramic target of the present invention is applied to the magnetron sputtering coating process to prepare a zinc-tin oxide film with a certain stoichiometric ratio, in an argon atmosphere, there is no need to feed oxygen, or the Zinc tin oxide thin film can be obtained by introducing oxygen with an oxygen flow rate of any value from 0 to 150 sccm. The zinc tin oxide film layer obtained by depositing zinc tin oxide ceramic target on the glass substrate has a uniform particle size. , The sputtering voltage is stable, the process is easy to control, the film layer has strong bonding force, and the film layer is compact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com