Projection optical engine

A technology of projection optics and engine, which is applied in the field of projection optical engine, can solve the problems of small light source area of light-emitting diodes, insufficient output brightness of projectors, limited light collection ability, etc., and achieves easy installation and arrangement of heat dissipation and air duct devices, and compact structure , the effect of small space size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

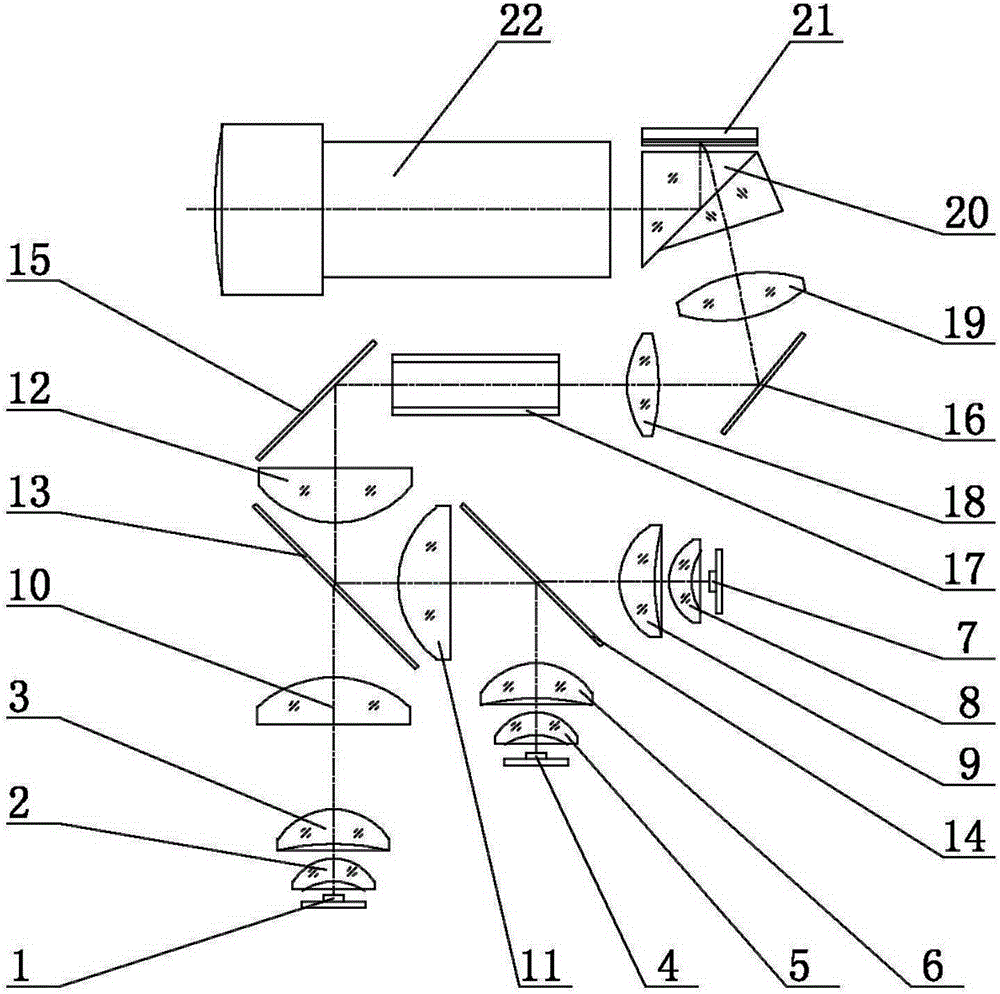

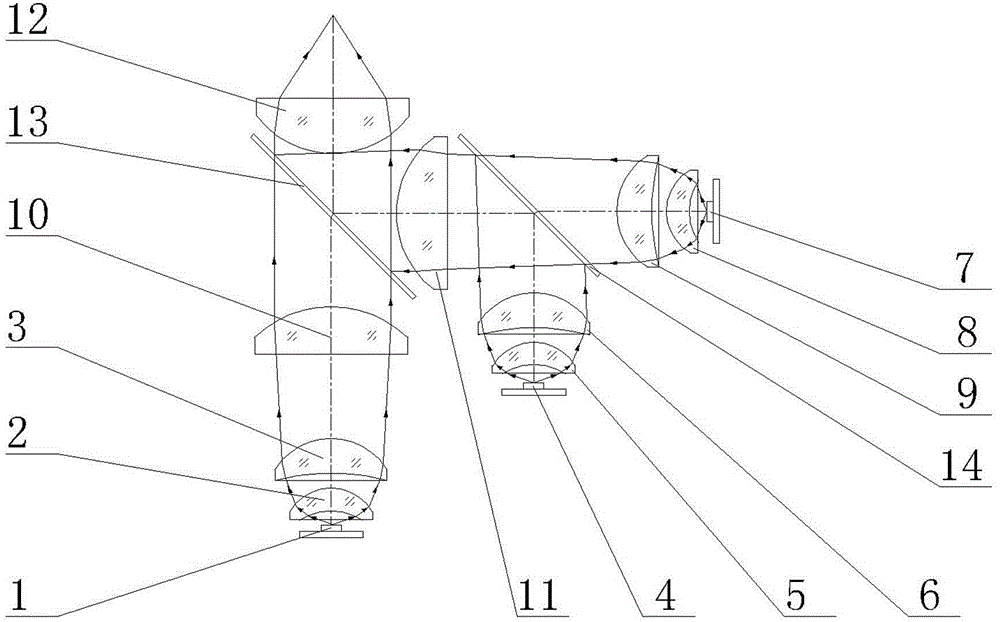

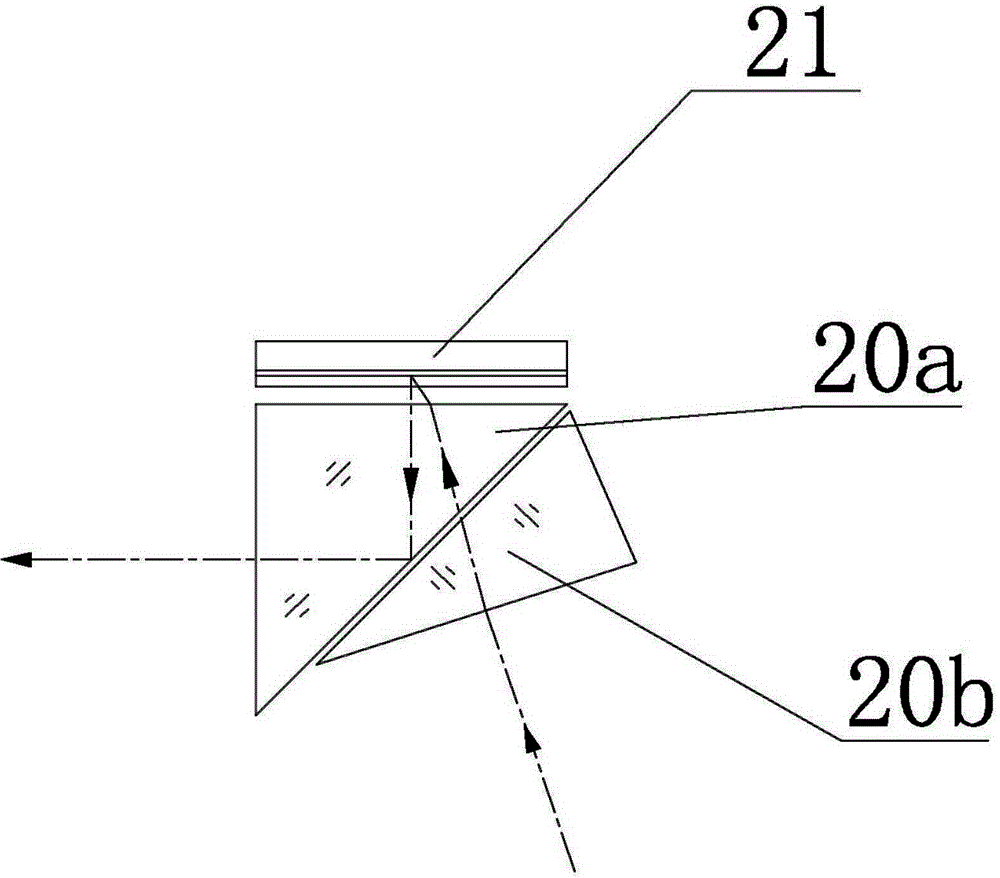

[0036] Such as figure 1 As shown, the projection optical engine proposed by the present invention includes: a first turning mirror 15, a light guide rod 17, a first relay lens 18, and a second turning mirror 16 arranged horizontally and sequentially; A light source is provided, and the top of the first turning reflector 15 is inclined towards the light source near the light guide rod 17, and the bottom is inclined; Display chip 21, the incident surface of total reflection prism 20 is inclined towards the second turning mirror 16, the second relay lens 19 is inclined and the angle of inclination matches the incident surface of total reflection prism 20, the second turning mirror 16 bottom Near the first relay lens 18, the top is inclined towards the incident surface of the total reflection prism 20, and the working surface of the digital micromirror display chip 21 is parallel to the outer surface of the total reflection prism 20 and towards the total reflection surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com