Method for preparing single-core MgB2 superconducting line/strip

A superconducting wire and single-core technology, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problem that the critical current density of the wire/strip cannot be significantly improved, dopants are difficult to play a role, and equipment conditions are very demanding. Advanced problems, achieve good chemical inertness, increase critical current density, and increase surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Single core MgB 2 Preparation of superconducting tape:

[0031] Step 1, mix magnesium powder, amorphous boron powder and micron-sized Ti powder according to the atomic ratio of Mg:Ti:B=0.8:0.2:4, mix them uniformly and press them into blocks, and place the blocks under argon gas Under the protection of the atmosphere, heat treatment at 900°C for 1.5h, after cooling, break the block, then add magnesium powder to the broken block according to the atomic ratio of Mg:Ti:B=0.9:0.1:2, and grind for 60min A mixed powder is obtained; the mass purity of the magnesium powder is not less than 99.8%, the particle size of the magnesium powder is -50 mesh, the mass purity of the amorphous boron powder is not less than 99%, and the mass purity of the micron Ti powder is not less than 99%, the particle size is -100 mesh;

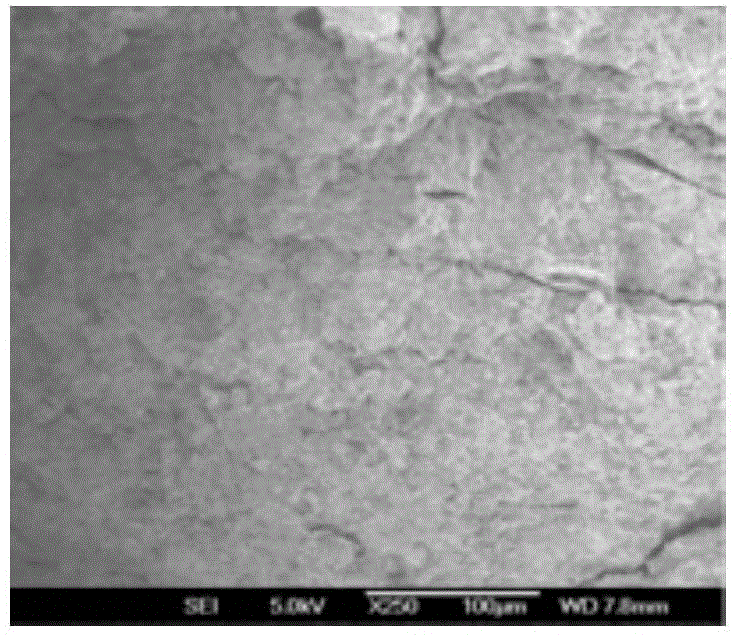

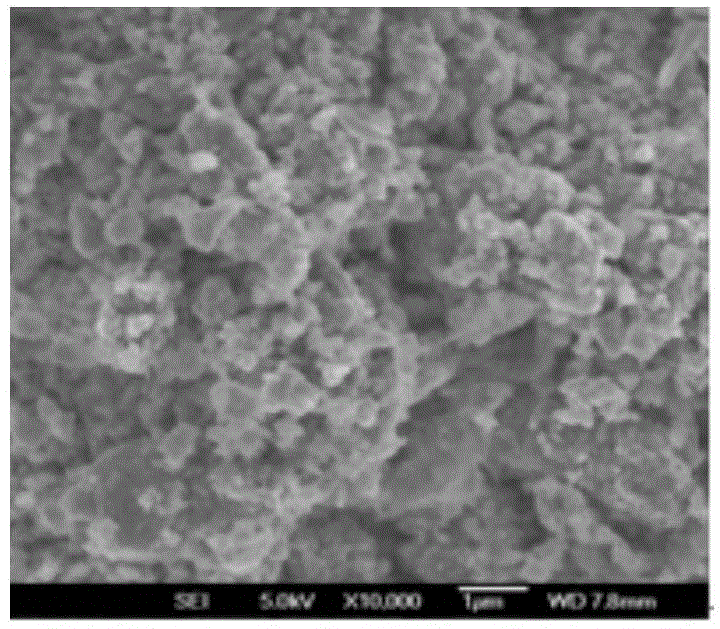

[0032] Step 2. Place the mixed powder described in step 1 in a high-energy ball mill, and high-energy ball-mill the mixed powder for 10 hours at a rotational speed...

Embodiment 2

[0046] Single core MgB 2 Preparation of superconducting tape:

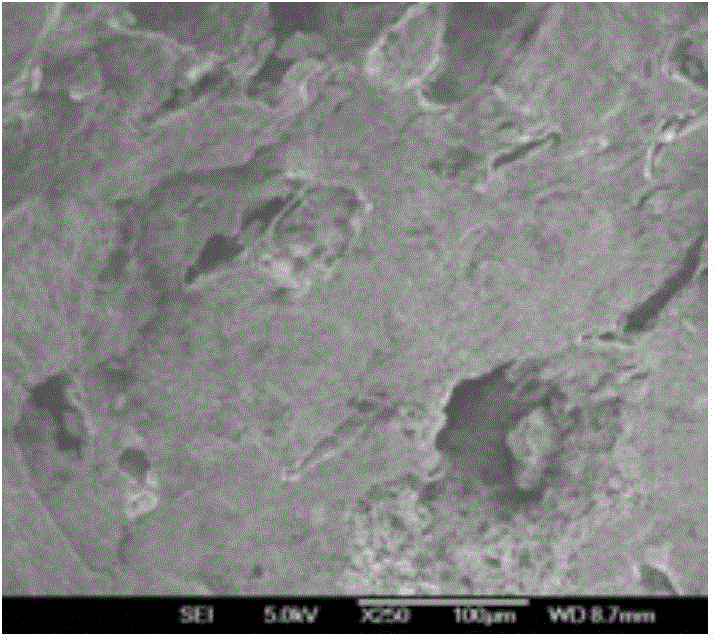

[0047] The preparation method of this embodiment is the same as that of Example 1, the difference being that step 5 is to roll the single-core wire described in step 4 into a single-core strip, and then seal both ends of the single-core strip Place in vacuum furnace and carry out vacuum sintering (vacuum sintering condition is the same as embodiment 1), obtains thickness and is 0.5mm, and width is 3.0mm single core MgB 2 Superconducting strip; the reduction ratios of the rolling passes are 20%, 20%, 15%, 10%, 10%, 10% and 10% in sequence.

[0048] In this embodiment, the supplemented magnesium powder in the step-by-step reaction process can bridge the microcracks formed in the processing process. In addition, due to the continuous fracture of powder particles during the high-energy ball milling process, a large number of fresh surfaces are produced, and the powder is milled to a certain extent by high-energy ball...

Embodiment 3

[0051] Single core MgB 2 Preparation of superconducting wires:

[0052] Step 1, mix magnesium powder, amorphous boron powder and micron-sized Ti powder according to the atomic ratio of Mg:Ti:B=0.98:0.02:4, mix them uniformly and press them into blocks, and place the blocks under argon gas Under the protection of the atmosphere, heat treatment at 800°C for 2 hours, after cooling, crush the block, then add magnesium powder to the crushed block according to the atomic ratio of Mg:Ti:B=0.99:0.01:2, and grind for 30 minutes to obtain Mixed powder; the mass purity of the magnesium powder is not less than 99.8%, the particle size of the magnesium powder is -50 mesh, the mass purity of the amorphous boron powder is not less than 99%, and the mass purity of the micron Ti powder is not less than 99% %, the particle size is -100 mesh;

[0053] Step 2. Place the mixed powder described in step 1 in a high-energy ball mill, and high-energy ball-mill the mixed powder for 20 hours at a spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com