Method for treating kitchen anaerobic waste water through short-cut nitrification and denitrification

A short-range nitrification and wastewater technology, applied in anaerobic digestion treatment, chemical instruments and methods, aerobic process treatment, etc., can solve the problems of high energy consumption, low total nitrogen removal efficiency, and many external carbon sources, etc., to achieve Avoid the effect of sludge bulking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 equipment and its operation

[0035] The water distribution tank 8 is preferably steel structure, design parameters: L×W×H=50cm×40cm×50cm, a stirring device 10 is installed on the top, the power is 100W, and the rotation speed is 40rpm. The feed pump is a peristaltic pump 9 (voltage: 220V, flow rate: 0.002-270ml / min), and a sampling port is provided 5cm from the bottom of the distribution tank. At the same time, according to the C / N ratio, an appropriate amount of raw kitchen water from the hydrolysis acidification tank of the company where the test was conducted was added as a carbon source for denitrification.

[0036] The high-efficiency biological denitrification reactor controls the temperature at 35±1°C and the pH at 7.0-8.5. Design parameters: glass structure, the size is D×H=10cm×220cm, bottom feeding is adopted, 4 distribution pipes are evenly distributed, and kitchen waste water, nitrification liquid and nitrosation liquid are mixed and fed at a ...

Embodiment 2

[0043] Example 2 Kitchen sewage treatment

[0044] The waste water of Jiangsu Clean Environment Technology Co., Ltd. after anaerobic fermentation was used as the raw material, and the water quality indicators of the waste water are shown in Table 1.

[0045] Table 1 Kitchen wastewater quality

[0046]

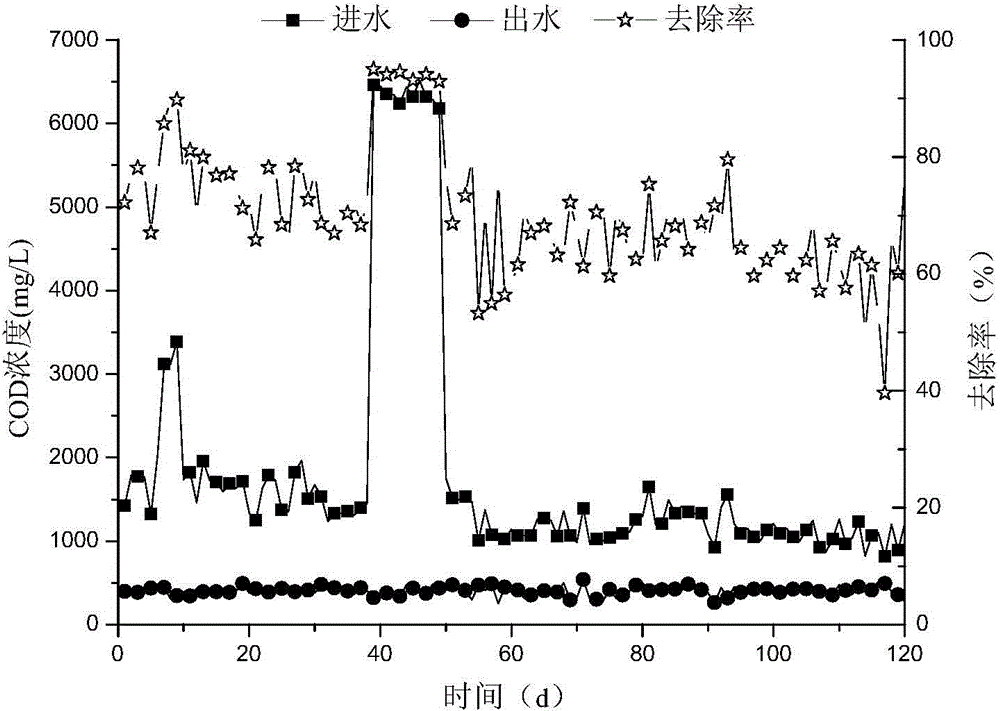

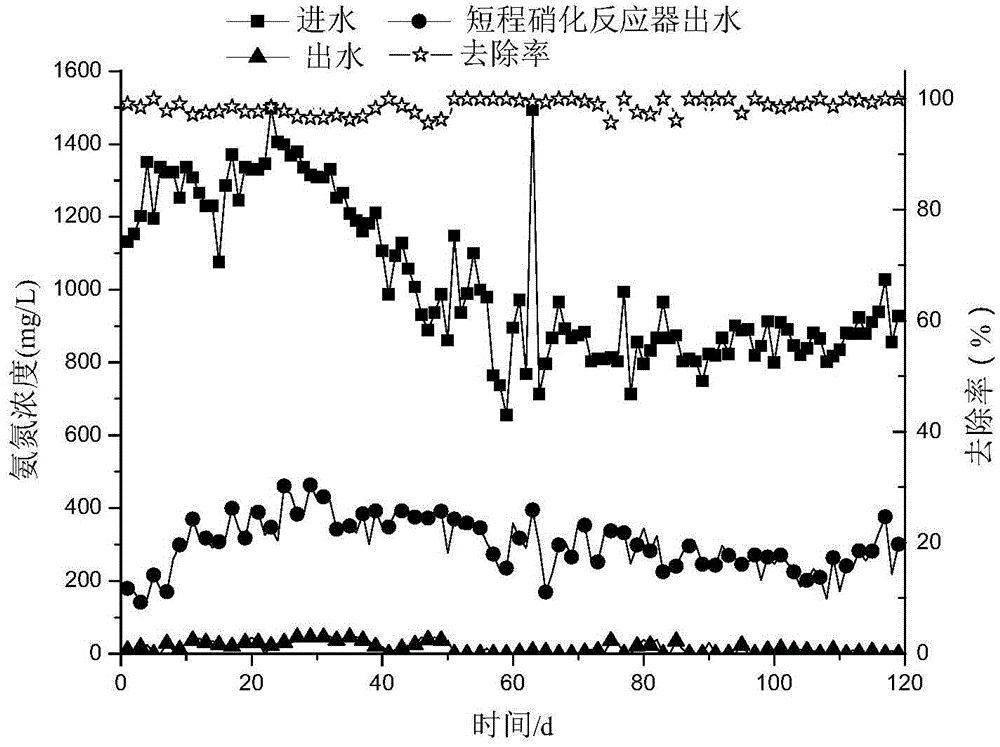

[0047] The waste water is mixed with the returning nitrosation liquid and nitrification liquid into the high-efficiency denitrification reactor, and then flows through the anoxic tank 1, the short-range nitrification reactor, the aerobic tank, the anoxic tank 2, and the sedimentation tank, and then overflows. During the operation of the process, the wastewater indicators monitored daily include: pH, COD, TN, NH 4 + -N, NO 3 - -N, NO 2 - -N, MLSS.

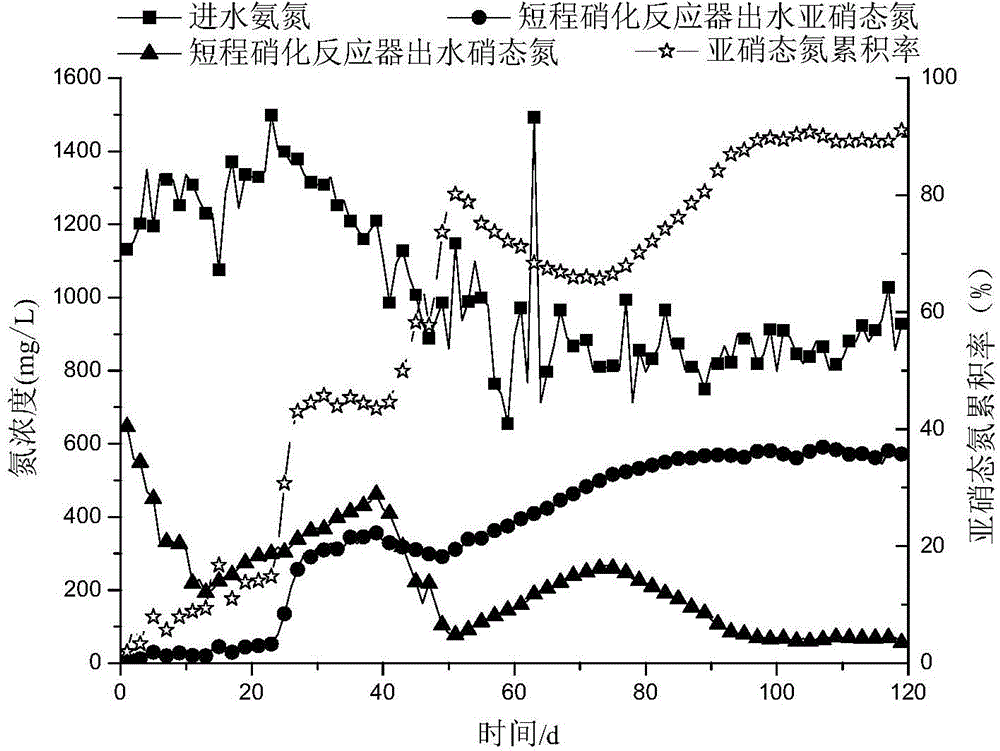

[0048] After a period of operation, the change trend of nitrite nitrogen accumulation rate in the short-cut nitrification reactor is as follows: figure 1 As shown, the influent water quality of the reactor fluctuates great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com