Sludge or soil treatment method and heavy metal component stabilizing agent

A soil treatment and heavy metal technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of increased treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

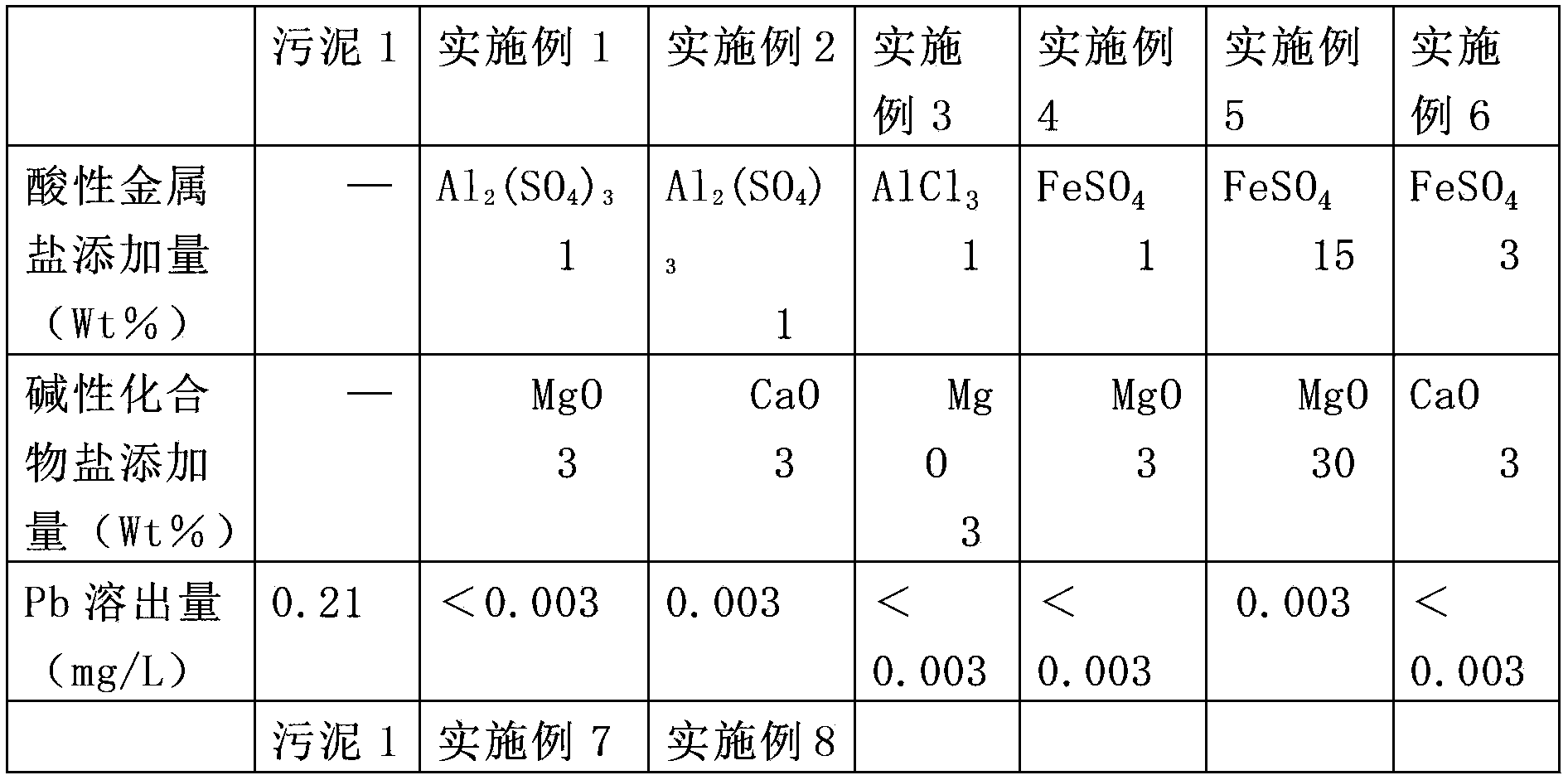

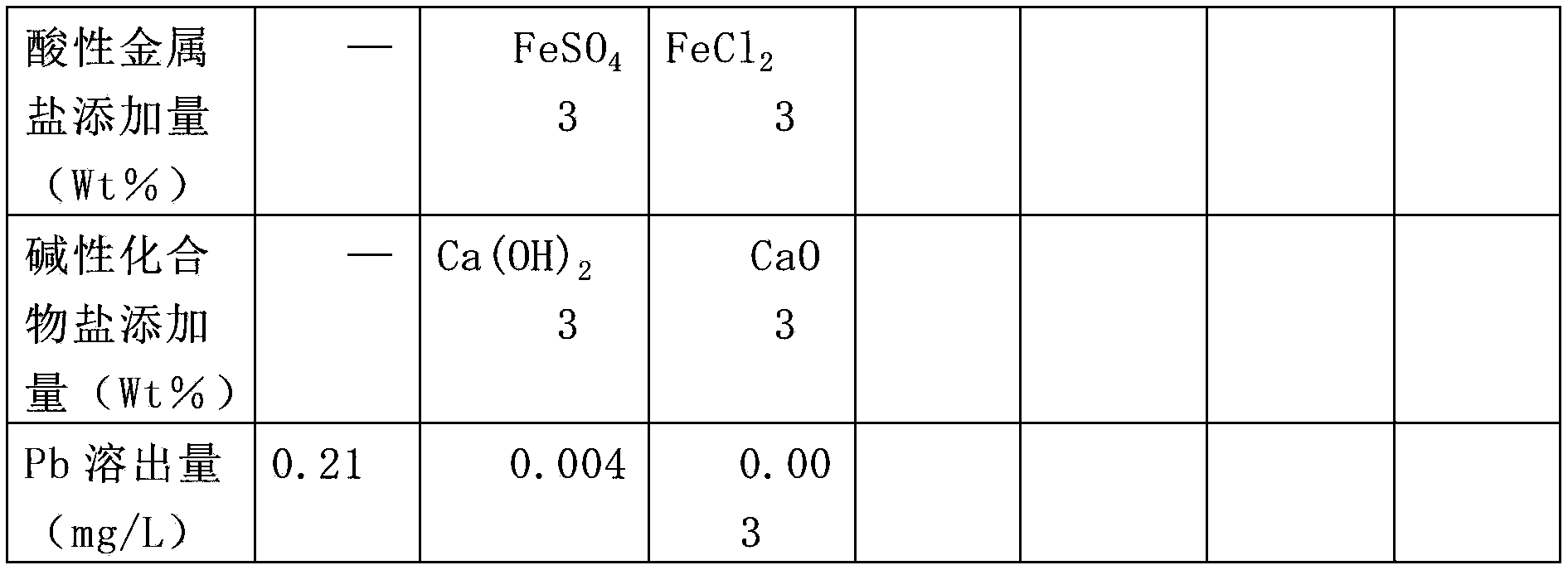

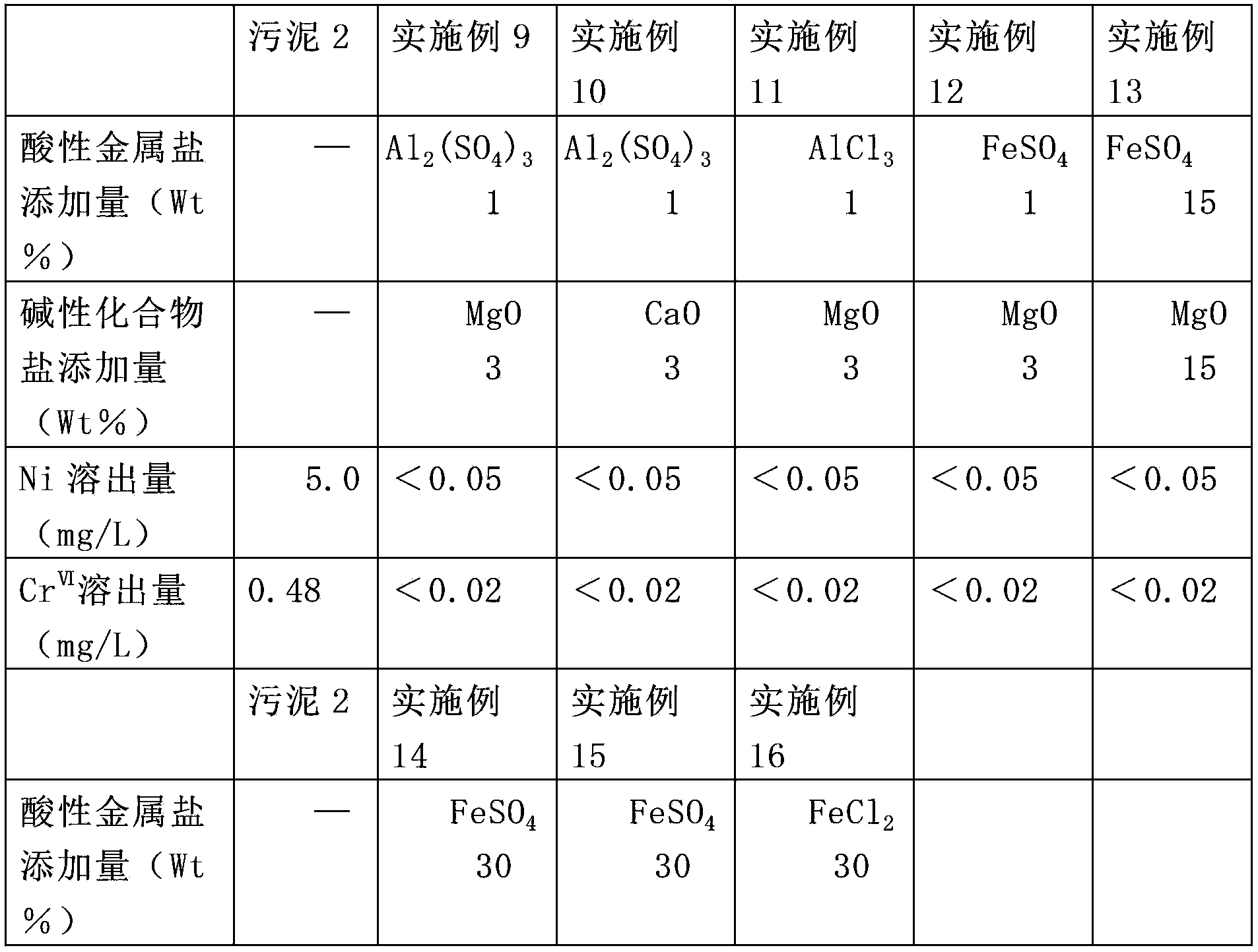

Examples

Embodiment Construction

[0010] The sludge or soil treated by the present invention is mainly inorganic sludge discharged from chemical factories, mines, smelters, ironworks, gold-plating factories, etc. Sludge soil produced in the process. The heavy metal components contained in these sludges or soils are ions containing at least one of arsenic, lead, cadmium, nickel, chromium (hexavalent), mercury, antimony, selenium, barium, and the like.

[0011] Ferric chloride, ferric nitrate, ferric sulfate, zinc chloride, zinc sulfate, copper chloride, copper nitrate, copper sulfate, zinc chloride, and manganese sulfate can be used as the acidic metal salt used in the heavy metal component stabilizing agent of the present invention. , aluminum chloride, aluminum sulfate, etc. In addition, it is more suitable to use environmentally friendly and low-cost ferric chloride, ferric sulfate, aluminum chloride, and aluminum sulfate. The iron salt at this time is preferably divalent or trivalent salt. Iron salt and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com