Method for preparing high-thermal-conductivity high-strength silicon nitride ceramic

A technology of silicon nitride ceramics and high thermal conductivity, which is applied in the field of non-oxide ceramic preparation, can solve the problem of high cost, and achieve the effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] With 5mol%Yb 2 o 3 and 5mol% MgO as a sintering aid, and 90mol% α-Si 3 N 4 The powder is mixed evenly by ball milling; then it is dry-pressed under 20MPa pressure, and then isostatically pressed under 200MPa pressure; it is then put into a graphite crucible and buried in Si 3 N 4 In the powder, pressure sintering was carried out at 1850° C. for 4 hours under a nitrogen atmosphere of 0.6 MPa; after the sintering, the sample was cooled to room temperature with the furnace.

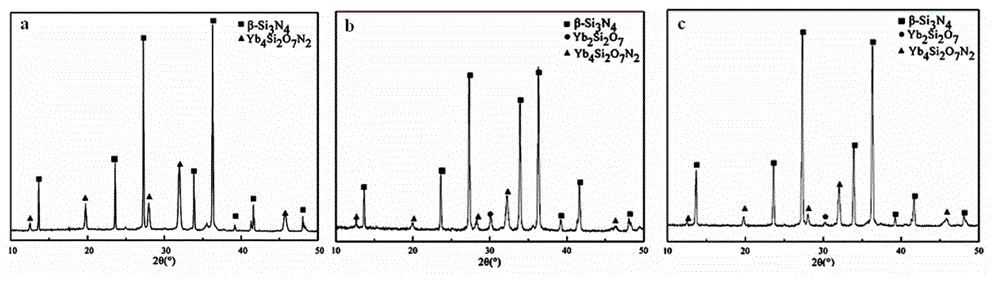

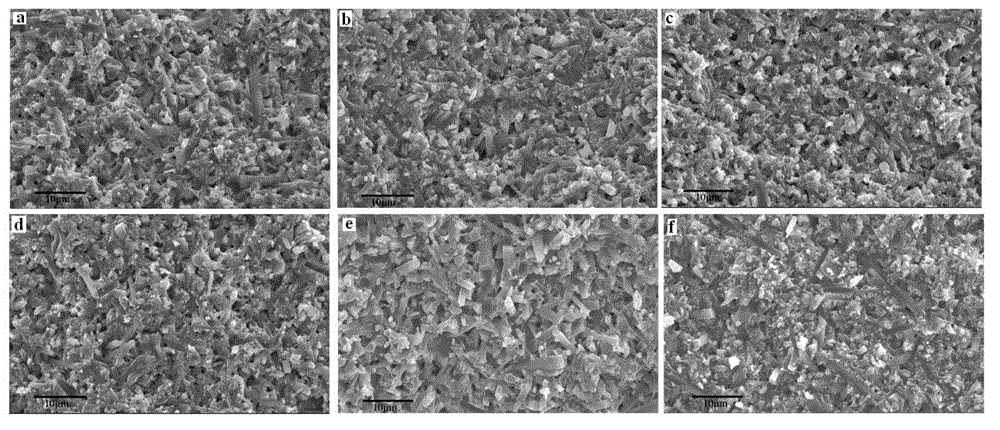

[0030]The thermal conductivity of the silicon nitride ceramics prepared in this example is 82W / (m·K), the three-point bending strength is 966MPa, and the fracture toughness is 6.29MPa·m 1 / 2 . The XRD pattern of the ceramic material is shown in figure 1 As shown in (a), the fracture morphology is as follows figure 2 (a) shown.

Embodiment 2

[0032] With 5mol%Yb 2 o 3 and 5mol% MgO as a sintering aid, and 90mol% α-Si 3 N 4 The powder is mixed evenly by ball milling; then it is dry-pressed under 20MPa pressure, and then isostatically pressed under 200MPa pressure; it is then put into a graphite crucible and buried in Si 3 N 4 In the powder, pressure sintering was carried out at 1800° C. for 4 hours under a nitrogen atmosphere of 0.6 MPa; after sintering, the sample was cooled to room temperature with the furnace.

[0033] The thermal conductivity of the silicon nitride ceramics prepared in this example is 64W / (m K), the three-point bending strength is 810MPa, and the fracture toughness is 5.93MPa m 1 / 2 . The XRD pattern of the ceramic material is shown in figure 1 As shown in (b), the fracture morphology is as follows figure 2 (b) shown.

Embodiment 3

[0035] With 5mol%Yb 2 o 3 and 5mol% MgO as a sintering aid, and 90mol% α-Si 3 N 4 The powder is mixed evenly by ball milling; then it is dry-pressed under 20MPa pressure, and then isostatically pressed under 200MPa pressure; it is then put into a graphite crucible and buried in Si 3 N 4 In the powder, pressure sintering was carried out at 1750° C. for 4 hours under 0.6 MPa nitrogen atmosphere; after sintering, the sample was cooled to room temperature with the furnace.

[0036] The thermal conductivity of the silicon nitride ceramics prepared in this example is 57W / (m·K), the three-point bending strength is 752MPa, and the fracture toughness is 4.91MPa·m 1 / 2 . The XRD pattern of the ceramic material is shown in figure 1 As shown in (c), the fracture morphology is as follows figure 2 (c) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Three point flexural strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com