C2 fraction selective hydrogenation method

A carbon distillate, selective hydrogenation technology, applied in the fields of hydrocarbons, chemical instruments and methods, hydrocarbon purification/separation, etc., can solve the problems of easy coking, catalyst coking deactivation, and no catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

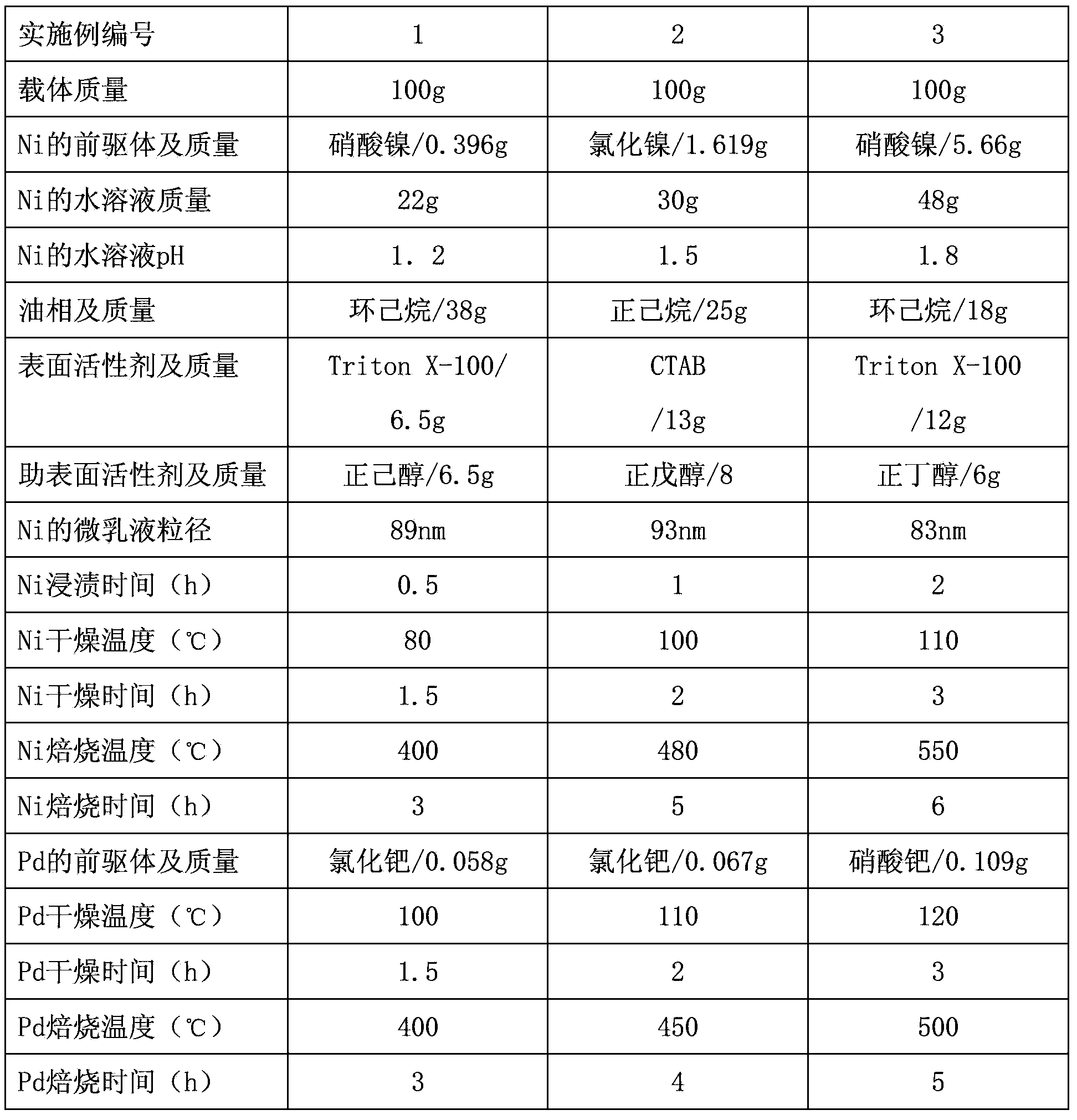

Embodiment 1

[0049] A commercially available bimodal pore distribution cylindrical alumina carrier with a diameter of 4 mm and a length of 4 mm was used. After calcination at 1200°C for 4 hours, the bimodal peaks of pore diameters are at 40nm and 100nm respectively, the pore volume is 0.6ml / g, and the specific surface area is 30m 2 / g.

[0050] The post-hydrogenation process is adopted, and the raw material composition is shown in Table 1.

[0051] Table 1 hydrogenation raw material composition

[0052] Hydrogenation feedstock

C 2 h 4

C 2 h 2

C 2 h 6

Content (mol%)

75.5

1.5

23

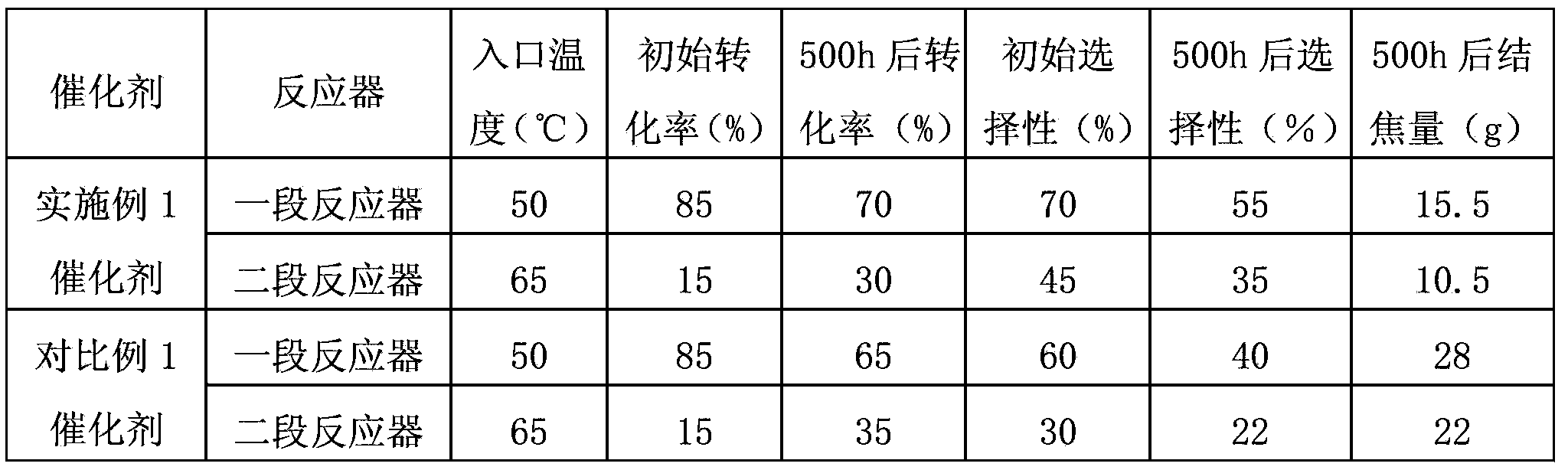

[0053] Process conditions: Two-stage adiabatic bed reactors are used.

[0054] Material air speed: 2000h -1 , Operating pressure: 1.5MPa, catalyst filling volume: 300ml. The inlet temperature of the first stage reactor is 50°C, and the inlet temperature of the first stage reactor is H 2 / C 2 h 2 =1:1 (V / V); the inlet temperature of the second stage ...

Embodiment 2

[0056] A commercially available bimodal pore distribution spherical alumina carrier with a diameter of 4 mm was used. After calcination at 1120°C for 4 hours, the bimodal peaks of the pore diameters are at 20nm and 150nm respectively, the pore volume is 0.4ml / g, and the specific surface area is 40m 2 / g.

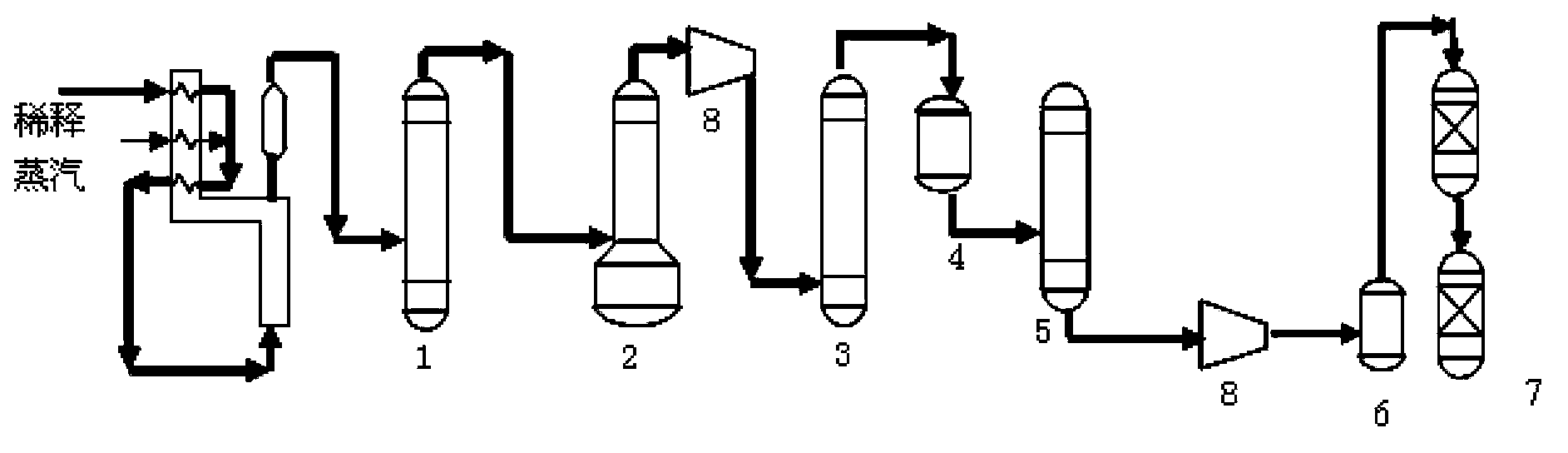

[0057] The post-hydrogenation process is adopted, and the process flow chart is as attached figure 1 Shown, raw material composition is as shown in table 2:

[0058] Table 2 hydrogenation raw material composition

[0059] Hydrogenation feedstock

C 2 h 4

C 2 h 2

C 2 h 6

Content (mol%)

80

1.5

18.5

[0060] Process conditions: Two-stage adiabatic bed reactors are connected in series, that is, the material from the outlet of the first-stage reactor enters the second-stage reactor. Each reactor has an independent gas distribution system.

[0061] Material gas space velocity: 5000h -1 , Operating pressure: 1.9MPa, ea...

Embodiment 3

[0063] A commercially available bimodal pore distribution four-leaf clover-shaped alumina carrier was used, with a diameter of 5.5 mm and a length of 4 mm. After calcination at 1150°C for 4 hours, the bimodal peaks of the pore diameters are 30nm and 200nm respectively, the pore volume is 0.3ml / g, and the specific surface area is 20m 2 / g.

[0064] Adopt post-hydrogenation process, reaction raw material composition is as shown in table 4 and is:

[0065] Table 3 hydrogenation raw material composition

[0066] Hydrogenation feedstock

C 2 h 4

C 2 h 2

C 2 h 6

Content (mol%)

80

2.5

17.5

[0067] Reaction conditions: Three-stage adiabatic bed reactor series process, that is, the outlet material of the first-stage reactor enters the second-stage reactor, and the outlet material of the second-stage reactor enters the third-stage reactor. Each reactor has an independent gas distribution system.

[0068] Material air speed: 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com