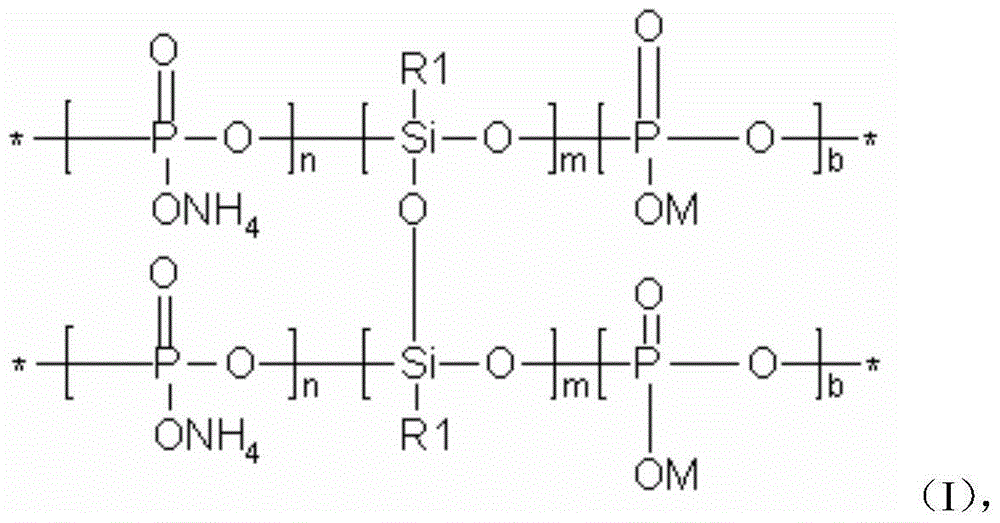

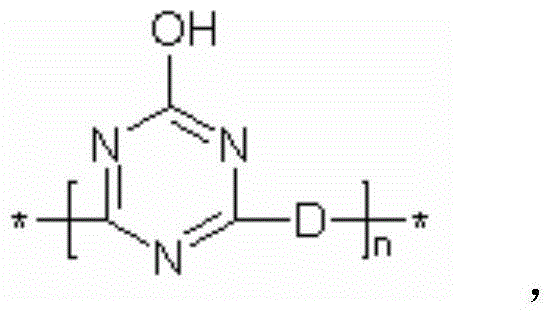

Migration resistant halogen-free intumescent flame retardant and preparation method and application thereof

An intumescent flame retardant, anti-migration technology, applied in the direction of organic chemistry, can solve the problems of poor compatibility, easy to be destroyed, low surface treatment efficiency, etc., achieve the effect of anti-migration and precipitation performance, and improve water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

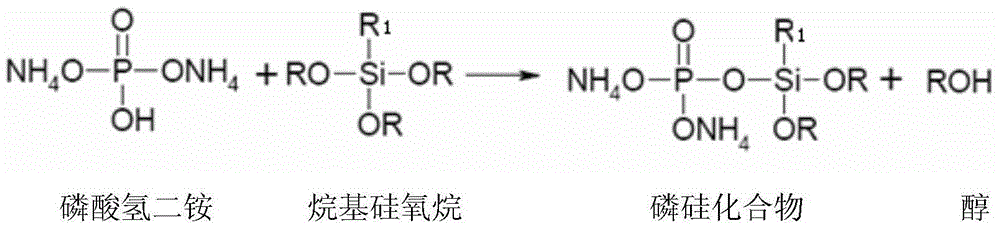

[0038] (1) Preparation of phosphorus silicon compound

[0039] The horizontal reactor is filled with nitrogen and vacuumized. After three cycles, 132 kg of diammonium hydrogen phosphate (required moisture <0.1%) is added under the protection of nitrogen. 136 kg of trimethoxysilane was stirred for 2 hours. Raise the temperature to 90°C, start vacuuming and devolatilization, the vacuum degree is 0.05Mpa, and continue the reaction for 10 hours to obtain the phosphorus silicon compound 1.

[0040] (2) Preparation of Polymer A

[0041] Put 23.6 kg of phosphorus silicon compound 1 and 105.6 kg of diammonium hydrogen phosphate (DAP) into the kneading reactor, stir evenly, add 0.10 kg of water, stir for 2 hours, add phosphorus pentoxide (P 2 o 5 ) 142 kilograms, stir evenly, start to heat up and ventilate ammonia. React at 200°C-280°C for 4 hours, wherein the ratio of the amount of ammonia introduced to the reactant is 100 kg, and the amount of ammonia passed through the reactant ...

Embodiment 2

[0047] The steps of Example 2 are the same as those of Example 1. In step (2), 11.8 kg of silicon-phosphorus compound 1 and 119 kg of diammonium hydrogen phosphate (DAP) are put into the step (2) to obtain a migration-resistant halogen-free intumescent flame retardant 2 .

Embodiment 3

[0049] (1) Preparation of phosphorus silicon compound

[0050] The horizontal reactor is filled with nitrogen and vacuumized. After three cycles, 132 kg of diammonium hydrogen phosphate (required moisture <0.1%) is added under the protection of nitrogen, and 198 kg of phenyltrimethoxysilane is sprayed under stirring at 100°C. , and stirred for 2 hours. Raise the temperature to 180°C, start vacuuming and devolatilization, the vacuum degree is 0.05Mpa, and continue the reaction for 8 hours to obtain the phosphorus silicon compound 3.

[0051] (2) Preparation of Polymer A

[0052] 34.2 kg of phosphosilicate compound 3 and 105.6 kg of diammonium hydrogen phosphate (DAP) were put into the kneading reactor. The rest of the preparation method is the same as in Example 1, and the migration-resistant halogen-free intumescent flame retardant 3 is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com