A low-density high-strength ceramsite fracturing proppant and its preparation method

A fracturing proppant and high-strength technology, applied in chemical instruments and methods, earthwork drilling, and fluid production, can solve the problems of high apparent density and high sintering temperature of products, achieve simple production process, reduce sintering temperature, promote The effect of sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

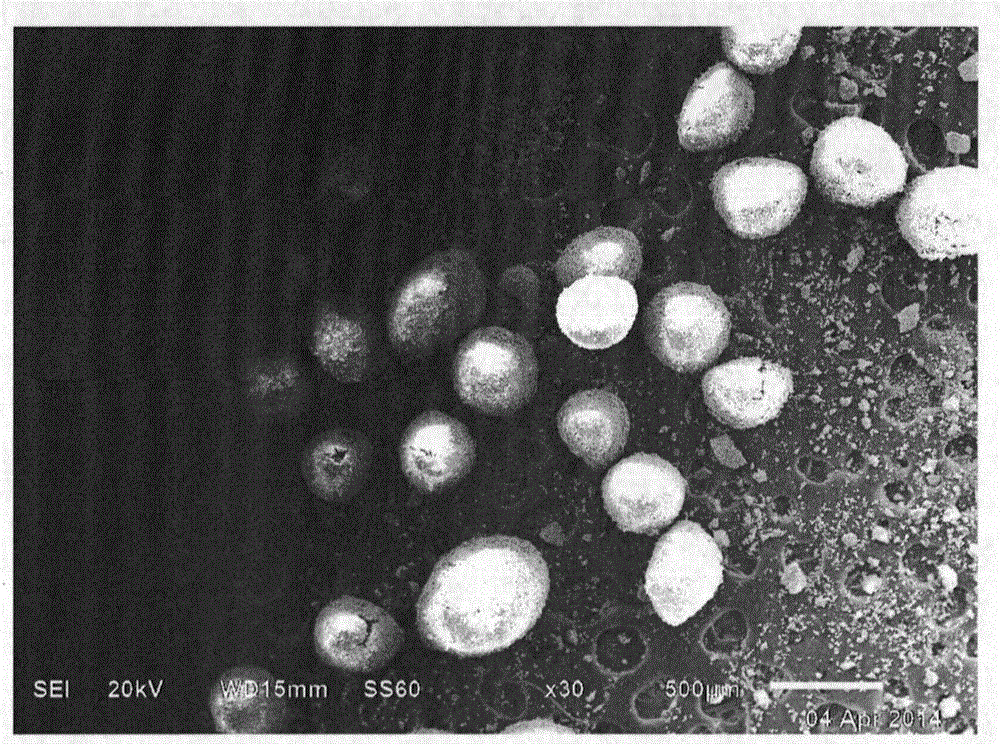

Image

Examples

Embodiment 1

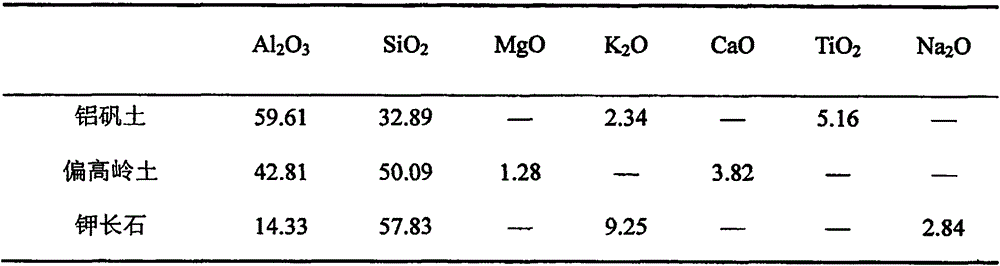

[0033] Embodiment 1: A low-density and high-strength ceramsite fracturing proppant, the ceramsite fracturing proppant has a core material embryo, and the raw material requirements and proportions are shown in Tables 1 and 2, in weight percentage;

[0034] A gel breaker layer is arranged outside the body of the core material, and an outer coating is coated on the gel breaker layer, and a lubricant layer is coated on the outer coating;

[0035] Wherein, the components of the breaker layer are selected from enzymes, perborate, sodium bromate, or combinations thereof;

[0036] This external coating is divided into internal coating and external coating, and the component of described internal coating is selected from phenolic resin, urea-formaldehyde resin or polyvinylidene chloride; The component of described external coating is selected from melamine formaldehyde resin, Furfuryl alcohol resins or copolymers of these resins;

Embodiment 2

[0041] Example 2: The raw material composition is shown in Table 1. The production method is basically the same as in Example 1, except that the semi-finished product is pre-calcined at 300°C for 1 hour in a furnace, and then the furnace temperature is raised to 1200°C for 10 hours.

Embodiment 3

[0042] Embodiment 3: The raw material composition is shown in Table 1, and the production method is basically the same as that of Embodiment 1, except that the semi-finished product is pre-calcined at 300° C. for 1 hour in a furnace, and then the furnace temperature is raised to 1250° C. for 10 hours of calcination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| sphericity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com