Acid-containing petroleum-coker gas oil mixing hydrogenation conversion method

A coking wax oil and hydrogenation conversion technology, which is applied in the field of mixed hydrogenation conversion of acid-containing petroleum and coking wax oil, can solve the problems that acid-containing petroleum and coking wax oil cannot be directly processed, and achieve the effect of reducing acidity and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

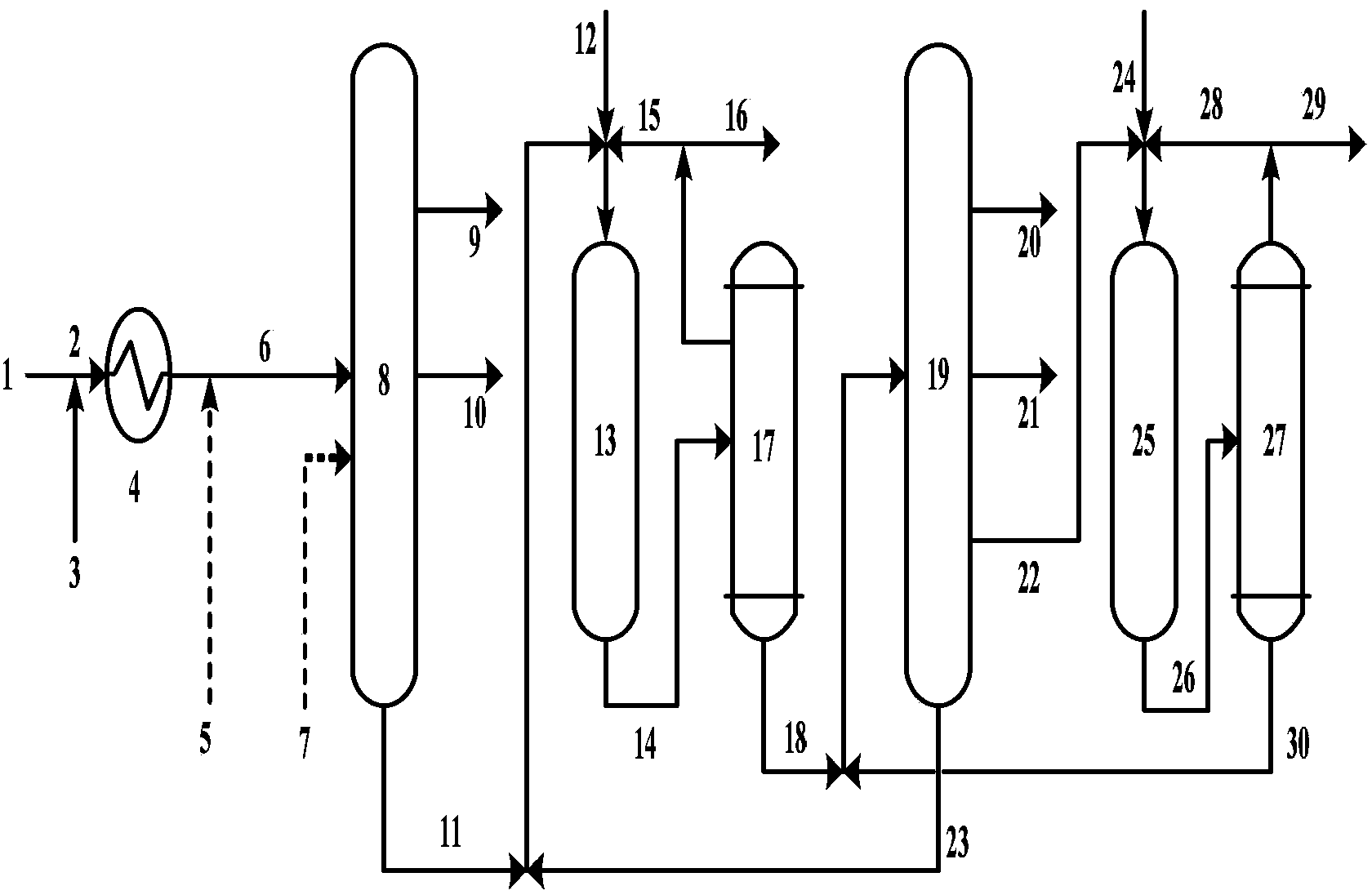

Method used

Image

Examples

Embodiment 1

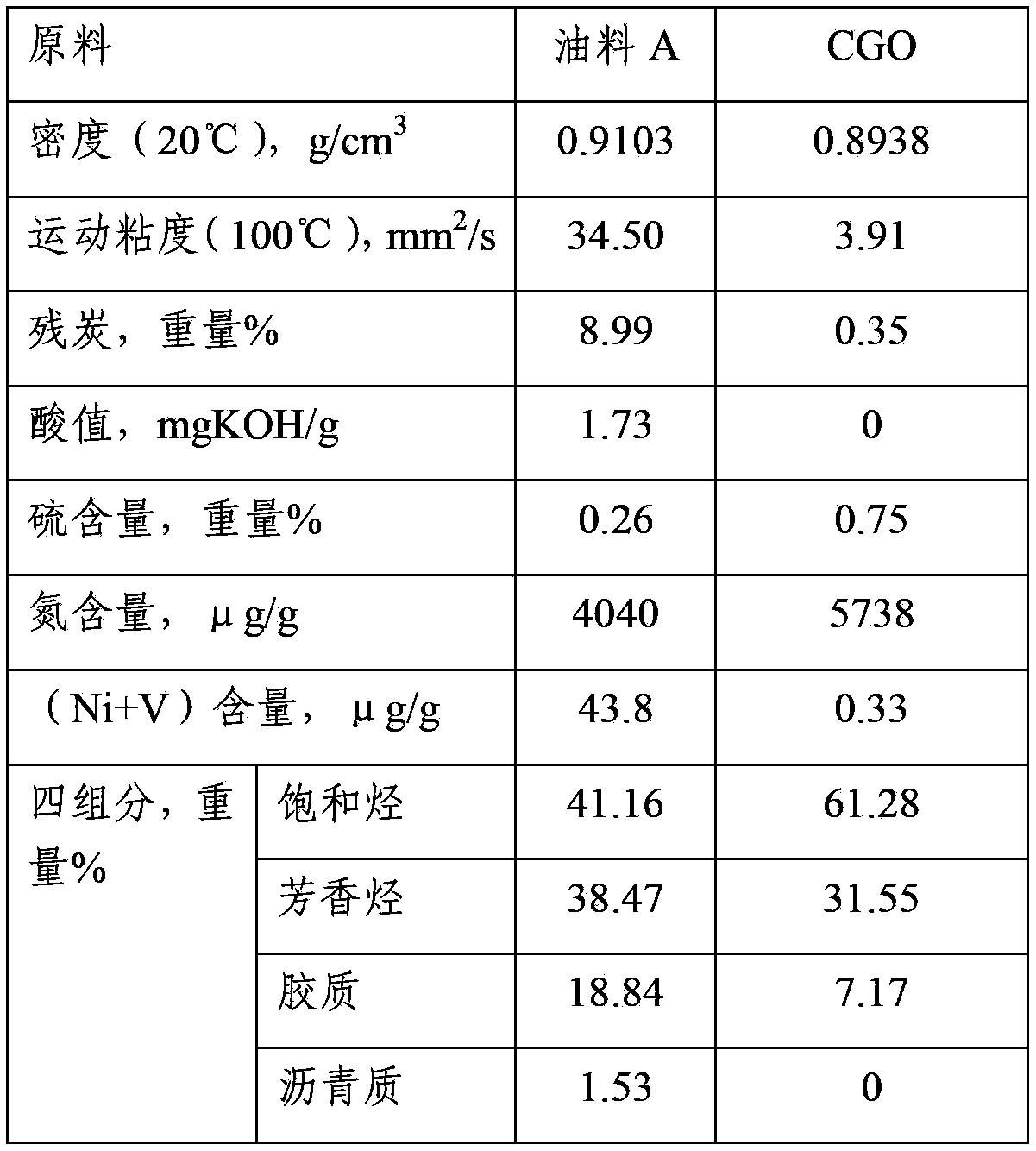

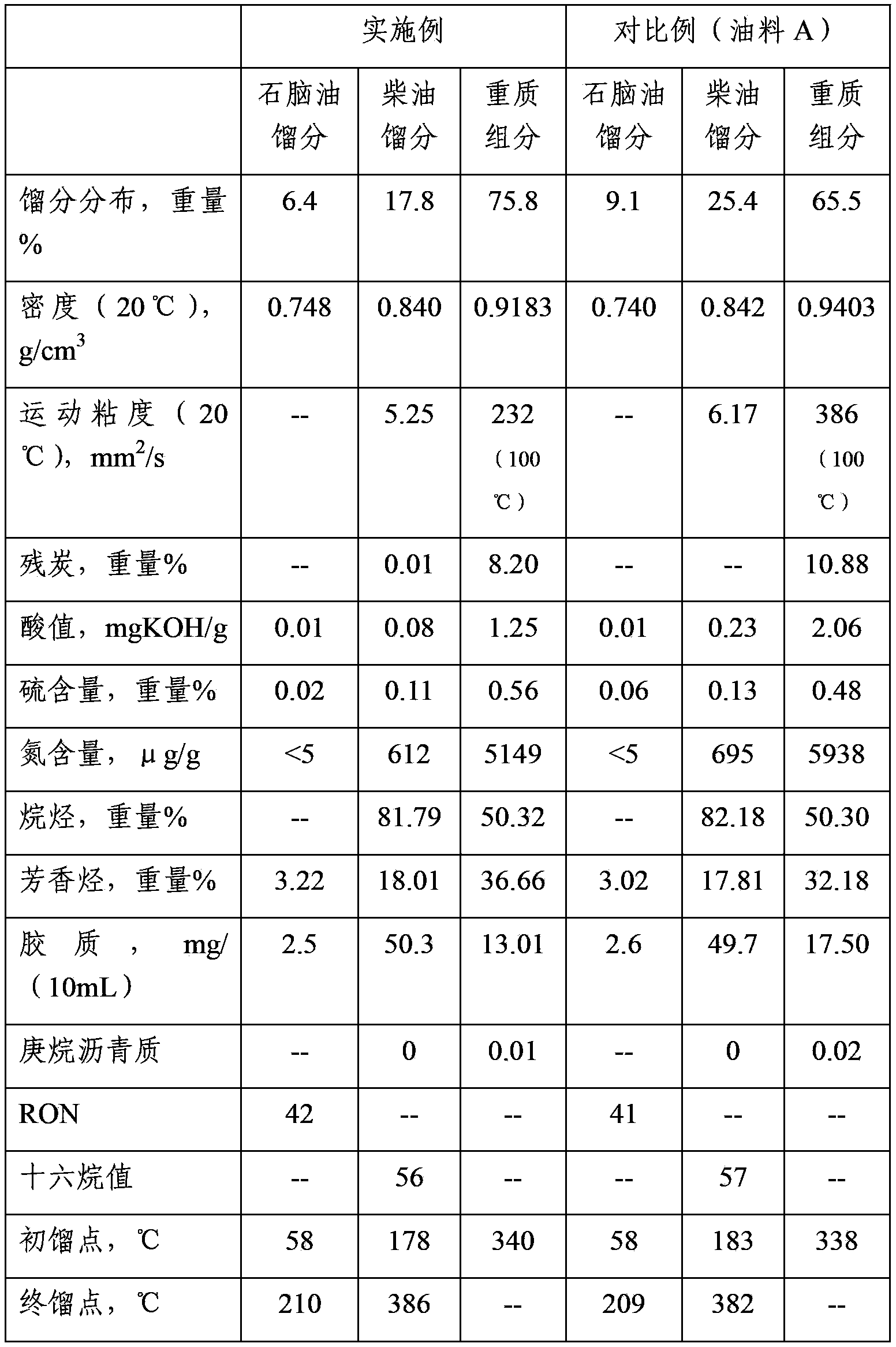

[0050] The acid-containing petroleum is oil A (see Table 1 for its properties), and the coking wax oil is obtained from the vacuum wax oil produced by the delayed coking process using vacuum residue from Liaohe Oilfield in China (see Table 1 for its properties). Mix oil material A with coker gas oil (hereinafter referred to as CGO) obtained from Liaohe vacuum residue according to the weight ratio of 7:3, put it into the tank reactor, pressurize it to 500kPa (gauge pressure) with nitrogen, and raise the temperature from room temperature to 180° C., react for 20 minutes under high-speed shearing and stirring conditions, and obtain pretreated raw material oil after cooling down to room temperature. The raw material oil was cut through a real boiling point distillation device to separate the naphtha fraction with IBP (initial boiling point) ~ 205 ° C, and the diesel fraction with 205 ~ 360 ° C, and finally obtained heavy components (see Table 2 for their properties). The obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com