The process of making bayberry wine

A technology and technology of dipping in sugar, which is applied in the field of making bayberry wine, can solve problems such as fruit drop, inedible green fruit, economic loss for growers, and short preservation time, and achieve the effect of shining and clear appearance, unique taste, and bright red color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

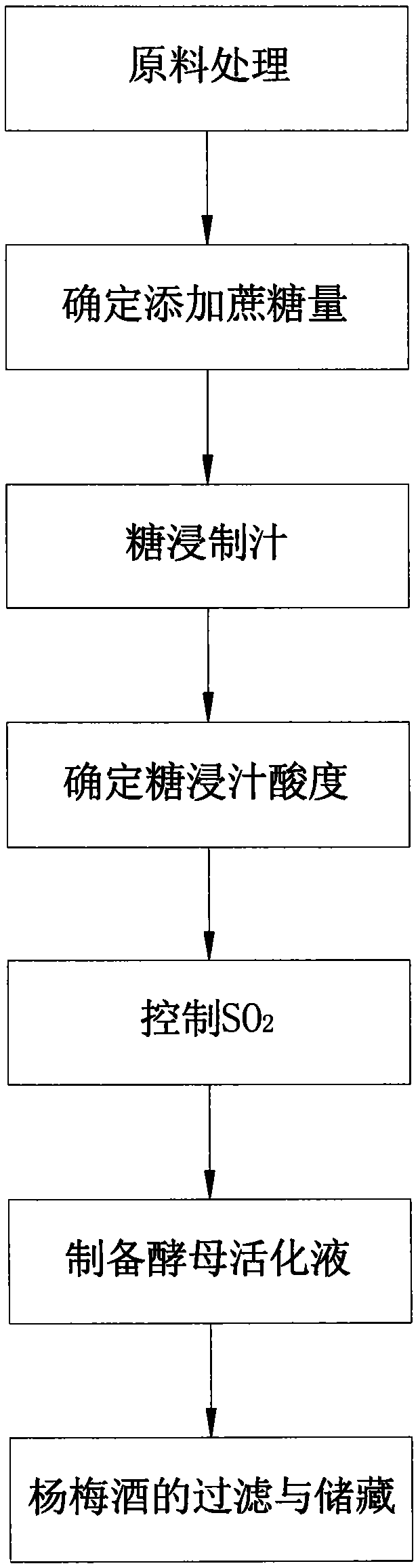

[0035] The process of making bayberry wine includes:

[0036] Step 1: Use red bayberry harvested in the same year, wash it with clean water for 3 times, wash away the sundries and soil attached to the red bayberry fruit, drain it with a steel mesh basket, and store it in a 4°C freezer.

[0037] Step 2: select a small amount of red bayberry in step 1 and squeeze it into fresh fruit juice, let it stand for clarification, and use an Abbe refractometer to detect its sugar content. Use sucrose to adjust red bayberry juice to reach the initial sugar content of fermentation. The initial sugar content of the red bayberry juice fermentation is 15%, and the added amount of sucrose is recorded.

[0038] Step 3: According to the sucrose addition data obtained in step 2, add sucrose and red bayberry fruit into the container in proportion, dip the red bayberry fruit in the container for 30 days in a cold storage at 4°C. The obtained sugar impregnation was filtered through a 10-mesh nylon f...

Embodiment 2

[0044] The difference between this embodiment and embodiment 1 is:

[0045] In the second step, the initial sugar content of bayberry fruit juice fermentation is 20%.

[0046] In the third step, the caramelization of bayberry fruit in the container is immersion in a 6°C cold storage for 40 days.

[0047] In step 4, distilled water is used to adjust the acidity of the red bayberry juice so that the initial acidity of fermentation is 0.5%.

[0048] In step five, the initial SO 2 The content is controlled at 125mg / kg.

[0049] In step 6, the yeast activation solution is prepared by adjusting the sugar content of the plum sugar infusion in step 4 to 5% with distilled water, dissolving 0.5 g of angel yeast in 20 mL of bayberry infusion, and activating at 38° C. for 15 minutes.

[0050]In step 7, the yeast activation solution is added according to the ratio of bayberry sugar extract and yeast activation solution at a ratio of 500:1. The sugar-soaked juice added with the yeast ac...

Embodiment 3

[0052] The difference between this embodiment and embodiment 1 is:

[0053] In the second step, the initial sugar content of bayberry fruit juice fermentation is 25%.

[0054] In the third step, the caramelization of red bayberry fruit in the container is 50 days in a cold storage at 8°C.

[0055] In step 4, distilled water is used to adjust the acidity of the red bayberry juice so that the initial acidity of fermentation is 0.7%.

[0056] In step 5, the initial SO 2 The content is controlled at 150mg / kg.

[0057] In step 6, the yeast activation solution is prepared by adjusting the sugar content of the plum sugar infusion in step 4 to 7% with distilled water, dissolving 0.4g of angel yeast in 18mL of bayberry infusion, and activating at 38°C for 15 minutes.

[0058] In step 7, the yeast activation solution is added according to the ratio of bayberry sugar infusion juice to yeast activation solution of 600:1.2. The sugar-soaked juice added with the yeast activation solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com