Composite flexible electrode material as well as preparation method and application thereof

A technology of electrode materials and flexible electrodes, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of insufficient utilization and development of flexible electrodes, and achieve stable cycle performance, excellent rate performance, and high specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

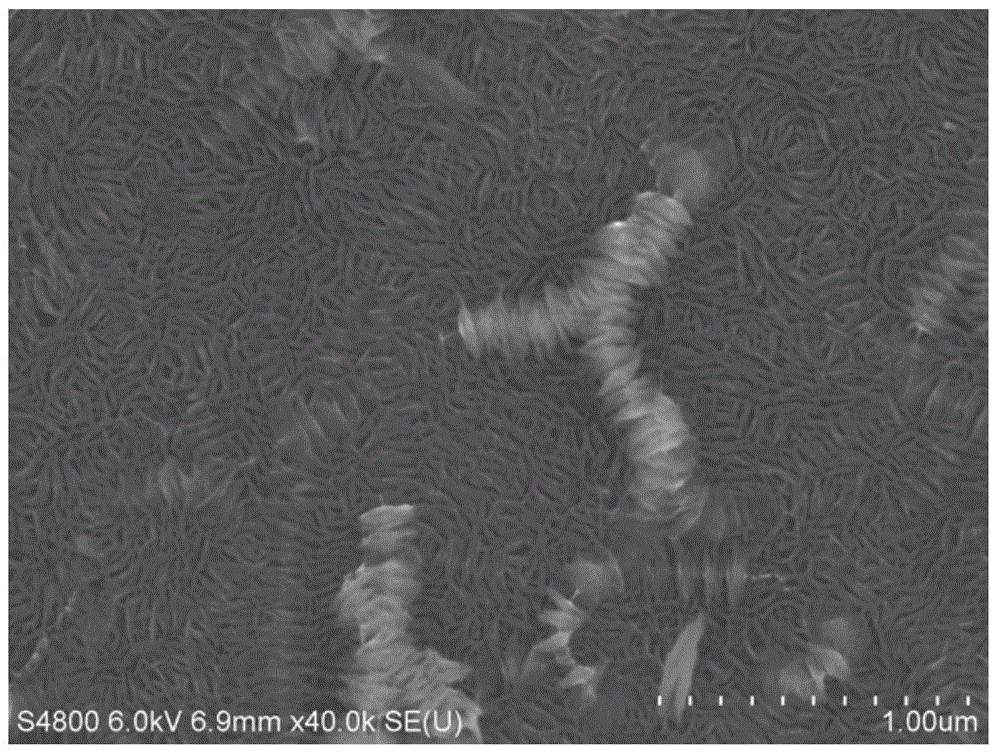

[0076] Weigh 50 mg of carbon nanotubes (Chengdu Institute of Organic Chemistry) and 100 mg of sodium deoxycholate (Sinopharm Chemical Reagent Company) into 100 mL of deionized water, and ultrasonicate at 200 W for 2 h.

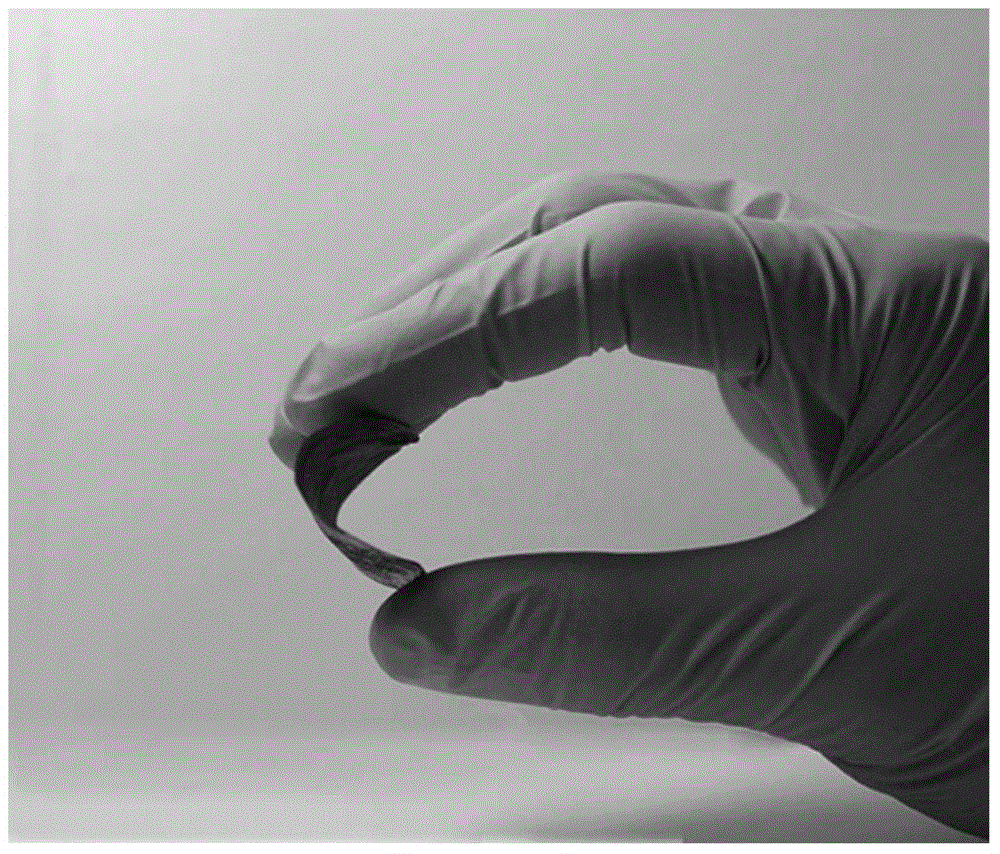

[0077] The carbon nanotube dispersion was suction-filtered, washed with deionized water to remove the surfactant, the carbon nanotube membrane was peeled off from the filter membrane, and dried overnight in a vacuum oven.

[0078] The carbon nanotube film is fixed in the self-made reaction container, add 33g4-chlorophenol (Bai Lingwei Technology Co., Ltd.) as solvent, add polymerized monomer pyromellitic dianhydride (Sinopharm Group Chemical Reagent Company) and ethylenediamine (Bai Lingwei Technology Co., Ltd.) to obtain a solution with a concentration of 0.2mmol / g, reflux for 9h, wash the membrane with acetone, dry it, heat-treat it at 300°C for 8h under an inert gas, wash the membrane with acetone, and dry it under vacuum overnight at 60°C to obtain Polyimi...

Embodiment 2

[0081] The polyimide / carbon nanotube composite electrode was prepared according to the method of Example 1, except that the amine was replaced by phenylenediamine to prepare an in-situ polymerized polyimide / carbon nanotube flexible composite film.

Embodiment 3

[0083] The polyimide / graphene composite electrode was prepared according to the method of Example 1, except that carbon nanotubes were replaced by graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com