Corrosion protection method for cable tray of cross-sea bridge in high salt-fog region

A technology for cross-sea bridges and cable trays, which is applied in the direction of electrical components, etc., and can solve the problem that the anti-corrosion system is no longer applicable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

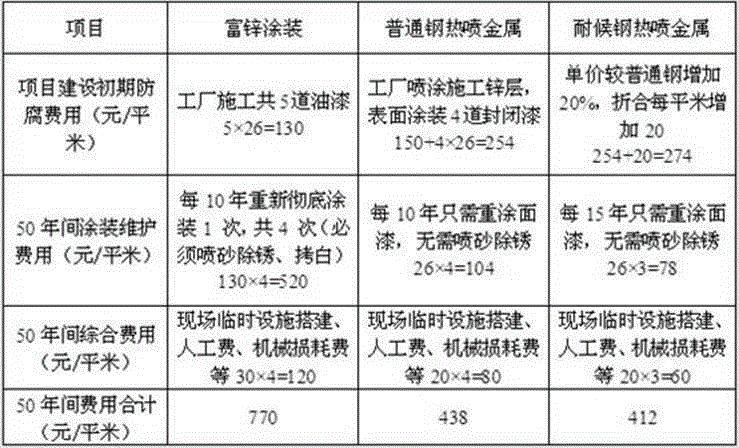

[0018] Q355GNH weathering steel is used as the main material of the bridge frame, and zinc-aluminum alloy with a volume ratio of 1:1 is thermally sprayed on its surface, and the metal coating is covered with epoxy cloud iron intermediate paint and fluorocarbon topcoat; Q235 hot-dip galvanized steel grating is used As the grid plate, A4-70 stainless steel bolts with the grade of 316L are selected. Compared with the existing cable trays, the cable trays thus made have good corrosion resistance, long service life, relatively easy daily maintenance, and low cost. And in the whole life of the project, the grid plate was replaced only once. Table 1 compares the economic investment of various anticorrosion schemes. It can be seen from Table 1 that the anti-corrosion scheme of the present invention has less economic investment than the common anti-corrosion scheme, and the anti-corrosion effect is better.

[0019] Table 1 Economic comparison of various anticorrosion schemes

[0020...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com