Pressure vessel with metallic liner and two fiber layers of different material

A technology for pressure vessels and metal linings, which is applied in the manufacture of pressure vessels, outer walls of vessel structures, and vessel structures. effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

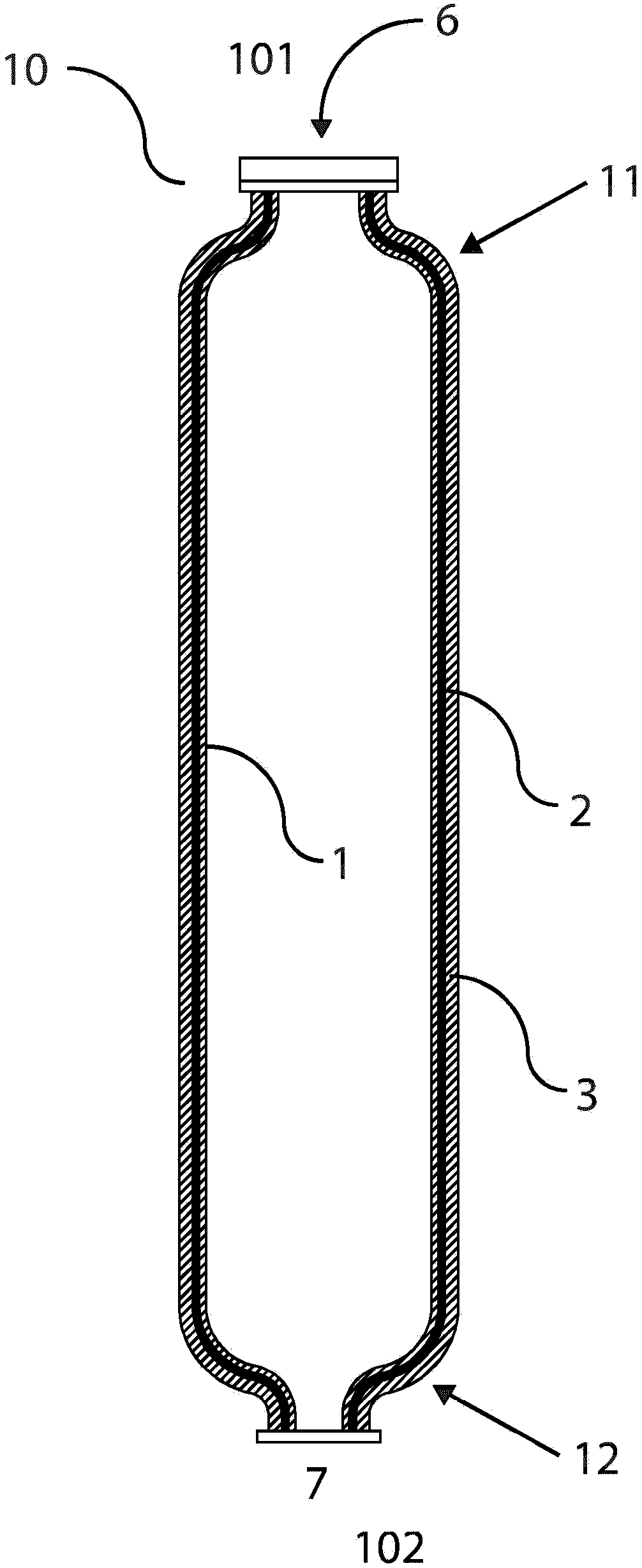

[0080] 1. The corrosion resistant metal lining is made of AISI 316 stainless steel with a tensile strength of at least 500 MPa and a carbon content of less than or equal to 0.08%, which is clad with a tensile strength of 3,200 MPa or greater and preferably Carbon fiber-based structural composites with a Young's modulus of 230 GPa or higher, each yarn of carbon fibers advantageously containing 12,000, 24,000 or 48,000 filaments, and for thermal insulation considerations, the outer second layer is made of tensile The tensile strength is at least 80MPa, and the heat transfer coefficient is about 0.2W·m -1 ·K -1 Made of non-reinforced epoxy resin.

[0081] 2. The corrosion-resistant metal lining is made of AISI 316 stainless steel with a tensile strength of at least 500 MPa and a carbon content of less than or equal to 0.08%, which is clad with a tensile strength of 3,200 MPa or greater and preferably Carbon fiber-based structural composites with a Young's modulus of 230 GPa or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com