Preparation method of three-dimensional graphene-protein composite aerogel

A protein composite, graphene technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., to achieve the effect of improving aggregation, good adsorption capacity, and enriching functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

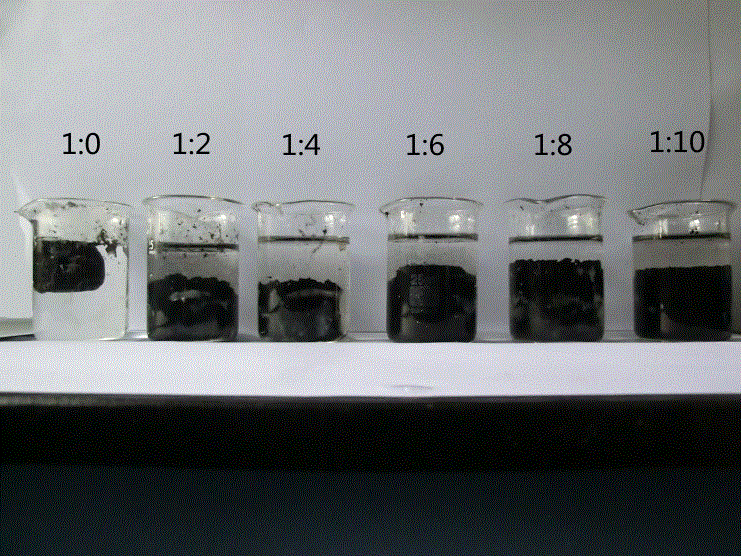

[0017] Take five beakers, respectively add 40mg of graphite oxide into 20mL of distilled water and perform ultrasonication for 6h until the solution is uniform to obtain a 2mg / L graphene solution. Add 40 mg of ascorbic acid to the five groups of beakers respectively, and sonicate for 1 hour until the solution is uniform, then add 0 g, 80 mg, 160 mg, 240 mg, 320 mg, and 400 mg of bovine serum albumin into the five groups of beakers, and sonicate for 1 hour until the solution is uniform.

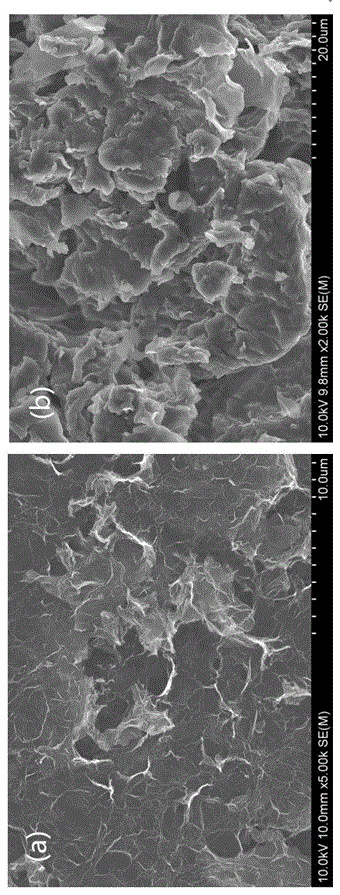

[0018] The solution was heated in a water bath at 80°C for 12h. After heating, pour out the water in the solution, pour distilled water into the hydrogel for 24 hours, and change the water every 12 hours. Pour off the solution in the beaker after soaking, the hydrogel is as figure 1 As shown, the hydrogel was freeze-dried for 24 hours to obtain a composite airgel, and the electron microscope was shown as figure 2 shown.

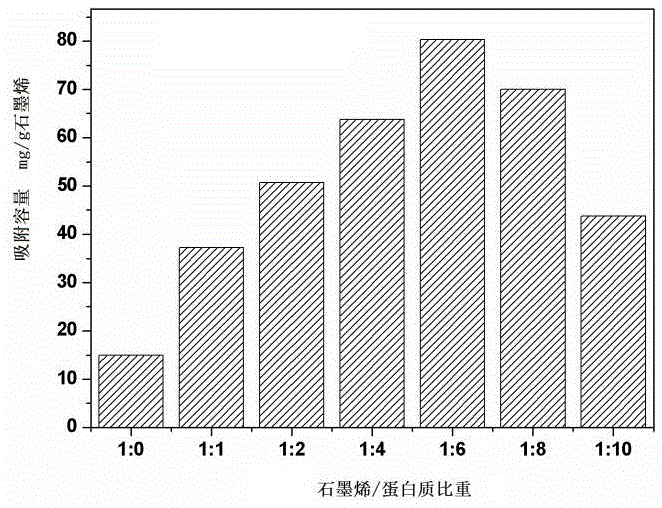

[0019] Five aerogels with different protein contents were added to 1...

Embodiment 2

[0021] Take five beakers, respectively add 40mg of graphite oxide into 20mL of distilled water and perform ultrasonication for 6h until the solution is uniform to obtain a 2mg / L graphene solution. Add 40mg of glutathione to the five groups of beakers respectively, and sonicate for 1h until the solution is uniform, then add bovine serum albumin 0g, 80mg, 160mg, 240mg, 320mg, 400mg to the five groups of beakers, and sonicate for 1h until the solution is uniform.

[0022] The solution was heated in a water bath at 80°C for 12h. After heating, pour out the water in the solution, pour distilled water into the hydrogel for 24 hours, and change the water every 12 hours. After soaking, the solution in the beaker was discarded, and the hydrogel was freeze-dried for 24 hours to obtain a composite airgel.

[0023] The three-dimensional graphene-protein airgel was added to a 10 mg / L tetracycline solution, and placed in a constant temperature shaker at 25°C for 24 hours. The aerogel had a...

Embodiment 3

[0025] Take five beakers, respectively add 40mg of graphite oxide into 20mL of distilled water and perform ultrasonication for 6h until the solution is uniform to obtain a 2mg / L graphene solution. Add 40mg of glutathione to the five groups of beakers respectively, and sonicate for 1h until the solution is uniform, then add soybean protein 0g, 80mg, 160mg, 240mg, 320mg, 400mg to the five groups of beakers, and sonicate for 1h until the solution is uniform.

[0026] The solution was heated in a water bath at 80°C for 12h. After heating, pour out the water in the solution, pour distilled water into the hydrogel for 24 hours, and change the water every 12 hours. After soaking, the solution in the beaker was discarded, and the hydrogel was freeze-dried for 24 hours to obtain a composite airgel.

[0027] The three-dimensional graphene-protein airgel was added to a 10 mg / L tetracycline solution, and placed in a constant temperature shaker at 25°C for 24 hours. The aerogel had a good...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com