A method for producing lightweight partition wall slats by recycling industrial slag and construction waste

A technology for lightweight partition wall slats and construction waste, which is applied in the direction of sustainable waste treatment, solid waste management, and climate sustainability. It can solve problems such as poor water absorption, product cracking, and easy caking, and achieve heat conduction Low coefficient and good thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

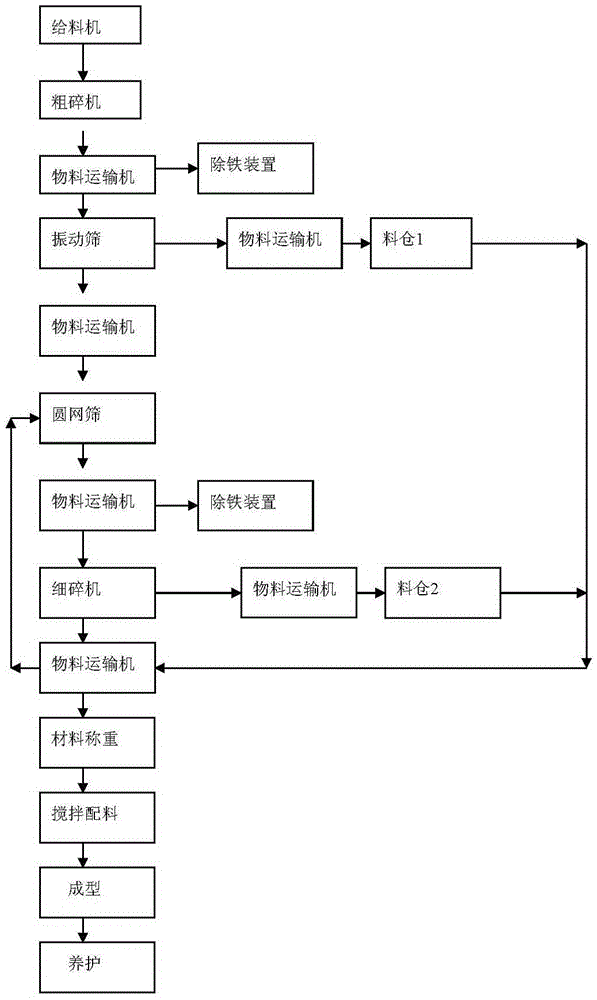

[0019] Embodiment: A kind of method of producing light-weight partition wall slats with industrial slag and construction waste recycling of this example, its steps are as follows figure 1 ,for:

[0020] a. The industrial slag is screened, and the fine material with a particle size of less than 5 mm is selected as the raw material for industrial slag regeneration, which is sent to the first silo through the material conveyor; after screening and separation, the industrial slag over 5 mm is transported to the crusher through the material conveyor After crushing, the crushed industrial slag particles below 5 mm are sent to the first silo through the material conveyor as recycled industrial slag particles for use. The material conveyor is equipped with an iron removal device to absorb the metal substances contained in the industrial slag. clear;

[0021] b. The construction waste is sorted, and then the first coarse crushing is carried out. The coarsely crushed construction was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com