Preparation method for silver nano wire transparent conductive film capable of preventing corrosion of hydrogen sulfide gas

A transparent conductive film, silver nanowire technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems that affect the continued use of conductive films, decrease in light transmittance and conductivity, and have not yet been provided, and achieve low cost. , Good conductivity and transmittance, anti-scratch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

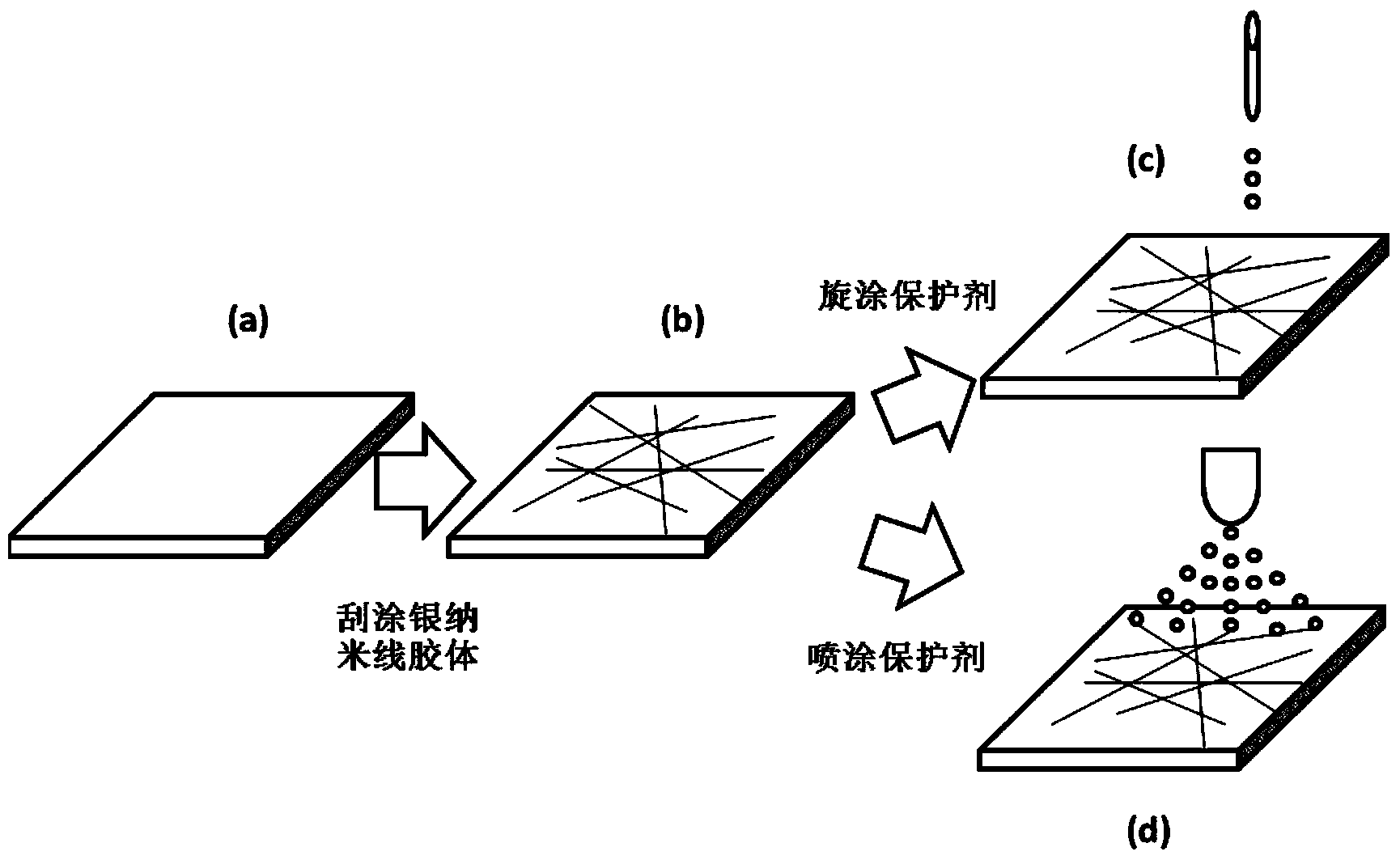

[0023] (1) Preparation of transparent conductive film substrate: Ultrasound the glass substrate or PET substrate in ethanol, acetone, and deionized water for 20 minutes respectively, after drying, clean it with a plasma cleaner for 15 minutes to make the surface hydrophilic;

[0024] (2) Preparation of silver nanowire transparent conductive film: use 3M adhesive tape (12.7mm wide x 33m long) to fix the substrate on the horizontal platform, take the silver nanowire colloid, scrape it on the fixed substrate with a glass rod, and blow it with a hair dryer Dry;

[0025] (3) Post-treatment of silver nanowire transparent conductive film. If it is a glass substrate, heat it on a heating plate at 200C for 20 minutes and then cool down naturally; if it is a PET substrate, process it with a press at 30MPa;

[0026] (4) Preparing a protective agent, taking PVA as an example: 5g of PVA can be dissolved in 95g of deionized water, heated and stirred at 90°C for 6h, and a 5% PVA aqueous sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com