Pharmaceutical composition of freeze-dried powder injection containing caspofungin

A freeze-dried powder injection, caspofungin technology, applied in freeze-drying transportation, drying solid materials, drying and other directions, can solve the problems of unfreeze-dried process comparison, low production efficiency, high energy consumption, and shorten the freeze-dried process. Dry cycle, improve production efficiency, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

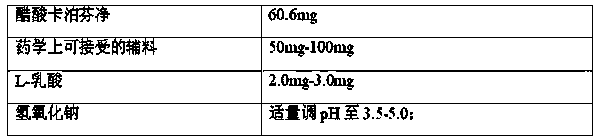

[0047] prescription:

[0048]

[0049] Preparation process: Weigh 90% of the total amount of water for injection and cool to room temperature, add L-lactic acid, stir well, adjust the pH value to 3.0-5.5 with sodium hydroxide solution; add sucrose and mannitol, stir to dissolve, add medicinal Charcoal, stirred and adsorbed, decarbonized and filtered. Cool the filtrate to below 15°C, add the prescribed amount of caspofungin acetate, stir to dissolve, and add water for injection to the full amount. Sterilization and filtration, filling, half-stoppering, putting into the box of a freeze dryer, freeze-drying, corking out of the box, and capping to obtain composition 1.

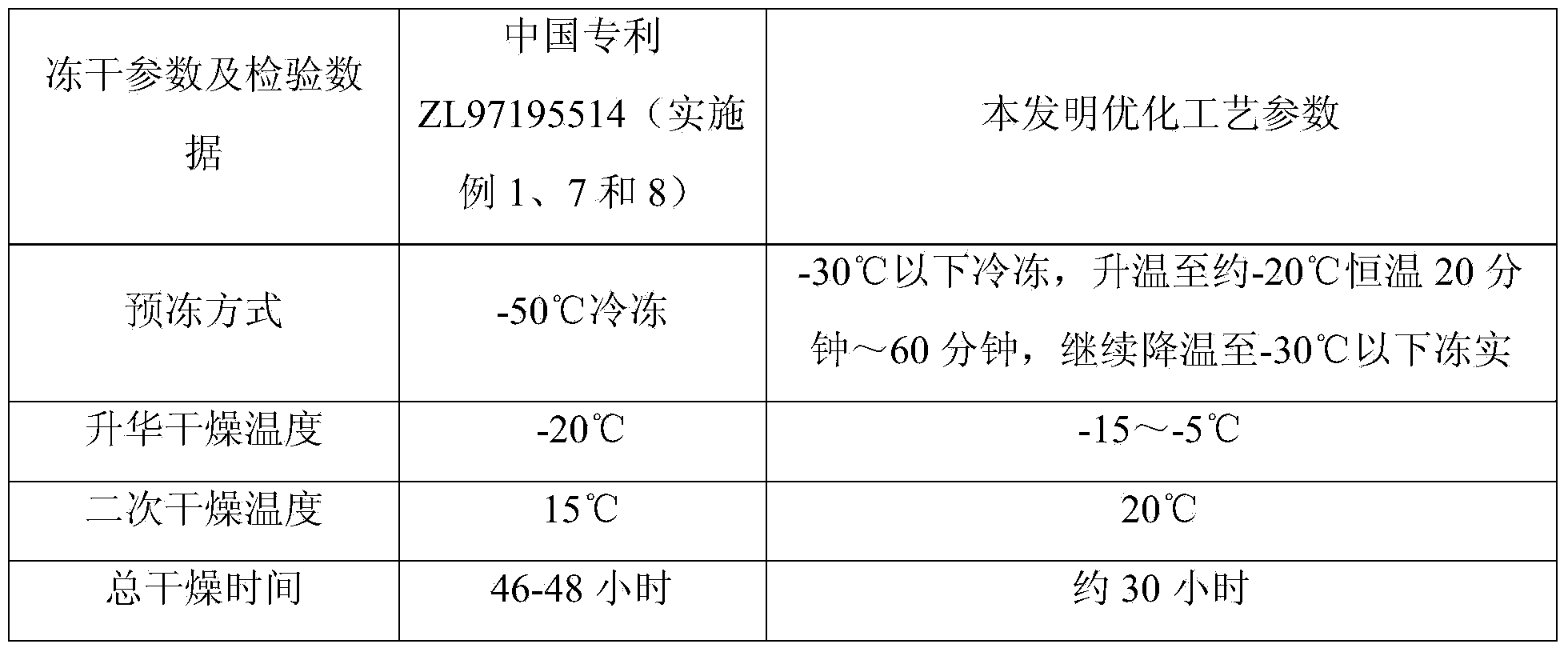

[0050] Freeze-drying process: cool down to -40°C to freeze, heat up to about -20°C for 20 minutes, continue to cool down to -40°C to freeze solid; vacuumize to 10Pa, heat up to -10°C for sublimation and drying; continue to heat up to 20°C to complete analysis dry.

Embodiment 2

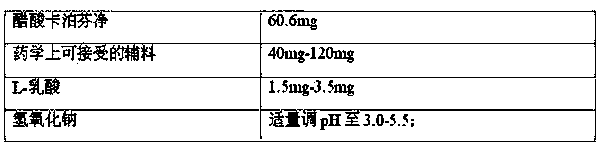

[0052] prescription:

[0053]

[0054]

[0055] Preparation process: Weigh 90% of the total amount of water for injection and cool to room temperature, add L-lactic acid, stir well, adjust the pH value to 3.0-5.5 with sodium hydroxide solution; add sucrose and mannitol, stir to dissolve, add medicinal Charcoal, stirred and adsorbed, decarbonized and filtered. Cool the filtrate to below 15°C, add the prescribed amount of caspofungin acetate, stir to dissolve, and add water for injection to the full amount. Sterilization and filtration, filling, half-stoppering, putting into the box of a freeze dryer, freeze-drying, corking out of the box, and capping to obtain composition 2.

[0056] Freeze-drying process: cool down to -35°C for freezing, heat up to about -20°C for 30 minutes, continue to cool down to -35°C for freezing; vacuumize to 15Pa, heat up to -15°C for sublimation and drying; continue to heat up to 20°C to complete analysis dry.

Embodiment 3

[0058] prescription:

[0059]

[0060] Preparation process: Weigh 90% of the total amount of water for injection and cool to room temperature, add L-lactic acid, stir well, adjust the pH value to 3.0-5.5 with sodium hydroxide solution; add sucrose and mannitol, stir to dissolve, add medicinal Charcoal, stirred and adsorbed, decarbonized and filtered. Cool the filtrate to below 15°C, add the prescribed amount of caspofungin acetate, stir to dissolve, and add water for injection to the full amount. Sterilization and filtration, filling, half-stoppering, putting into the box of a freeze dryer, freeze-drying, corking out of the box, and capping to obtain composition 3.

[0061] Freeze-drying process: cool down to -32°C for freezing, heat up to about -20°C for 60 minutes, continue to cool down to -32°C for freezing; vacuumize to 20Pa, heat up to -5°C for sublimation and drying; continue to heat up to 20°C to complete analysis dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com