Surplus sludge loaded photocatalyst as well as preparation method and application thereof

A photocatalyst and excess sludge technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as high cost, low load rate, and complicated preparation process, and achieve clean environment and high load rate High and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

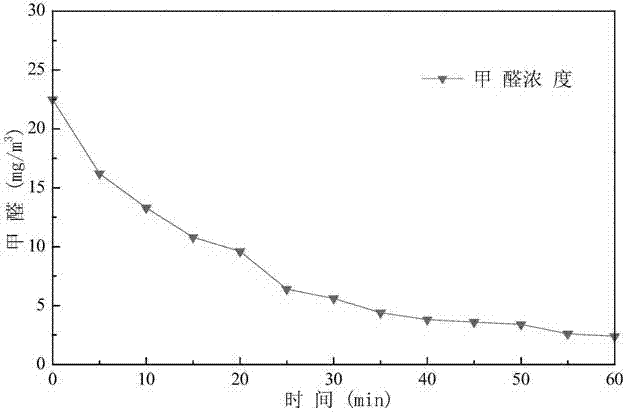

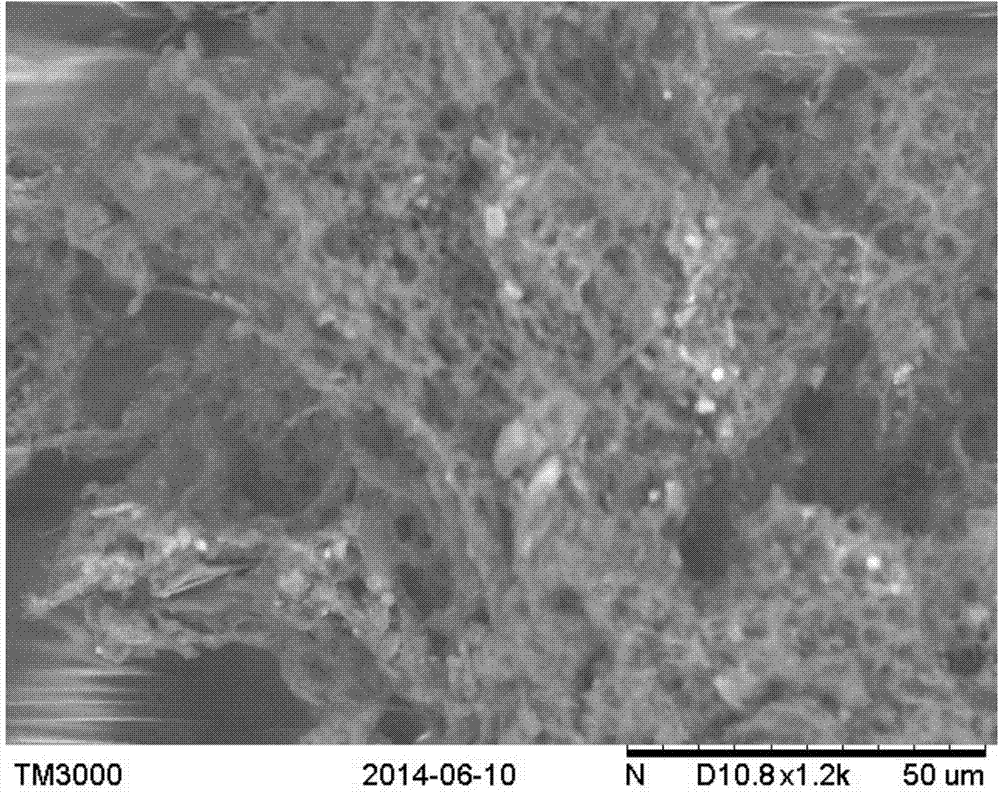

[0037] Embodiment 1: a kind of excess sludge loaded photocatalyst of the present invention, described photocatalyst is loaded on the excess sludge carrier, through calcining, grinding, obtains excess sludge loaded photocatalyst ( figure 1 ). The obtained excess sludge loaded photocatalyst is placed in a container containing formaldehyde, and irradiated with ultraviolet light, so as to achieve the purpose of degrading formaldehyde.

[0038] The preparation method of the above-mentioned residual sludge loaded photocatalysis comprises the following steps:

[0039] (1) Weighing: Weigh the remaining sludge carrier and TiO according to the mass ratio of 6:1 2 catalyst of light;

[0040] (2) Mixing: Mix the weighed remaining sludge carrier and photocatalyst evenly;

[0041] (3) Calcination: calcining the mixed mixture in a muffle furnace with the temperature set at 540°C;

[0042] (4) Grinding: load the remaining sludge after calcination with TiO 2 The photocatalyst is ground i...

Embodiment 2

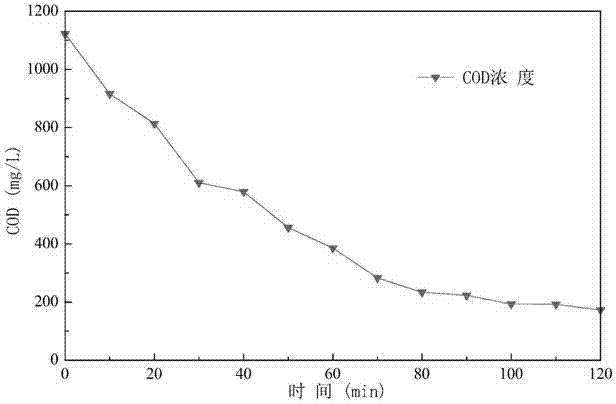

[0050] Embodiment 2: a kind of excess sludge loaded photocatalyst of the present invention, described photocatalyst is loaded on the excess sludge carrier, after calcining, grinding, generate excess sludge load photocatalyst, the gained excess sludge load photocatalyst is placed In organic wastewater, and irradiated with ultraviolet light, so as to achieve the purpose of treating organic wastewater.

[0051] The preparation method of the above-mentioned excess sludge loaded photocatalyst comprises the following steps:

[0052] (1) Weighing: Weigh the remaining sludge carrier and TiO according to the mass ratio of 6:1 2 catalyst of light;

[0053] (2) Mixing: mix the weighed remaining sludge carrier with TiO 2 The photocatalyst is mixed evenly;

[0054] (3) Calcination: calcining the mixed mixture in a muffle furnace with the temperature set at 540°C;

[0055] (4) Grinding: load the remaining sludge after calcination with TiO 2 The photocatalyst is ground into granules. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com