Efficient low heat input and double-wire surfacing method

A low-heat, high-efficiency technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of large welding heat input, reduced performance of welded joints, large deformation of base metal, etc., and achieve small welding heat affected zone and electric energy utilization The effect of high rate and fast solidification of weld seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

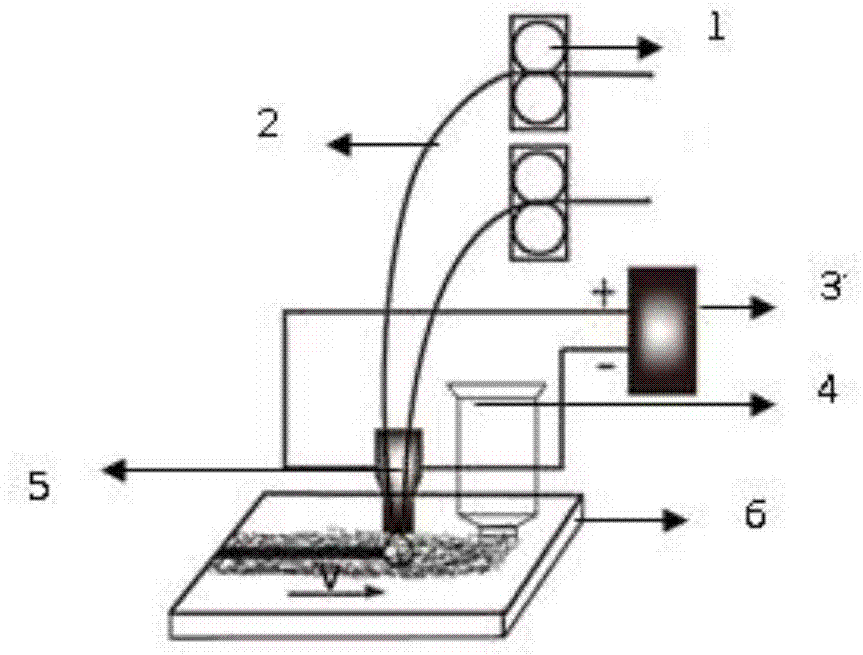

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Put the flux on the base metal to be welded, use a welding torch that contains two welding wires and the two welding wires are at an angle of 30°, connect the two welding wires with the positive and negative electrodes of the power supply respectively, and send the welding wire to the welding seam to be welded. position, arc ignition, the end of the welding wire starts arcing under the flux and burns stably for welding, the welding power supply adopts DC power supply, adopts H08A welding wire, welding current 200A, double wire diameter 1.2mm, and when the flux is HJ431, the welding available welding The seam surface is smooth and beautiful, and the cladding efficiency is twice that of traditional submerged arc welding under the same welding current, and the deformation of the base metal is small.

Embodiment 2

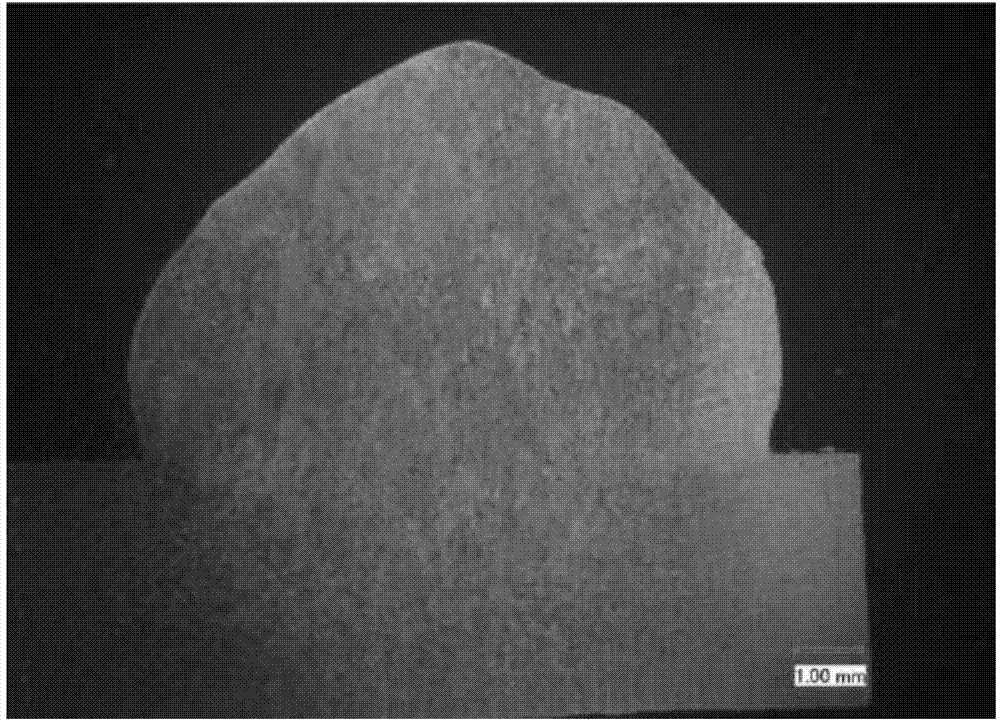

[0021] Embodiment 2: Put the flux on the base metal to be welded, use a welding torch that contains two welding wires and the two welding wires are at an angle of 25°, connect the two welding wires with the positive and negative electrodes of the power supply respectively, and send the welding wire to the welding seam to be welded Position, arc ignition, the end of the welding wire starts arcing under the flux and burns stably for welding. The welding power source adopts DC power supply, and the stainless steel is surfacing on the ordinary Q345 steel plate, using H0Cr21Ni10 welding wire, welding current 140A, double wire diameter 1.2mm, flux When HJ260 is selected, the weld seam with smooth and beautiful surface can be obtained, the deformation of the base metal is very small, and the plate base metal does not need to be corrected after surfacing welding, and the intergranular corrosion test of the surfacing layer can fully meet the requirements of use.

Embodiment 3

[0022] Embodiment 3: Put the flux on the base metal to be welded, use a welding torch that contains two welding wires and the two welding wires are at an angle of 30°, connect the two welding wires with the positive and negative electrodes of the power supply respectively, and send the welding wire to the welding torch to be welded. Position, arc ignition, arc ignition at the end of the welding wire and stable combustion, surface surfacing welding, welding power supply adopts DC power supply, wear-resistant surfacing welding on ordinary Q345 steel plate, adopts HS114 cobalt-based surfacing welding wear-resistant welding wire, welding current 260A , The diameter of the double wire is 2.0mm, when the flux is HJ107, a surfacing layer with a hardness greater than HRC55 can be obtained, the deformation of the base metal is very small, and there is no need to correct the plate base material after surfacing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com