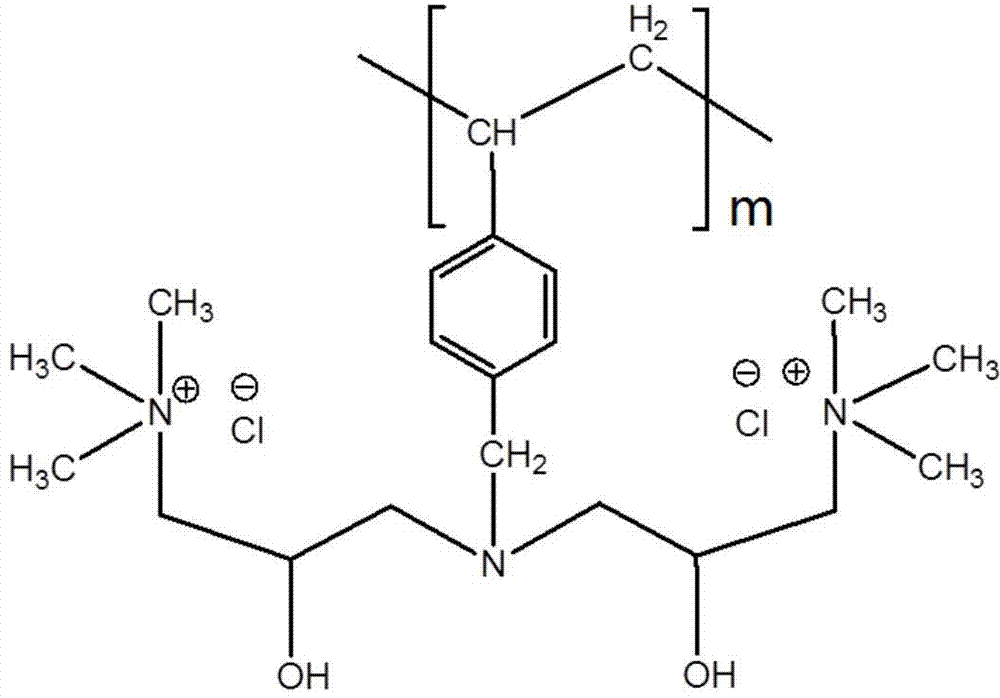

Anionic exchange resin with bifunctional group and synthesis method thereof

A technology of exchange capacity and exchange resin, applied in the direction of anion exchange, organic anion exchanger, ion exchange, etc., can solve the problems of limited number of quaternary ammonium salt groups, difficult to improve, etc., and achieve the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

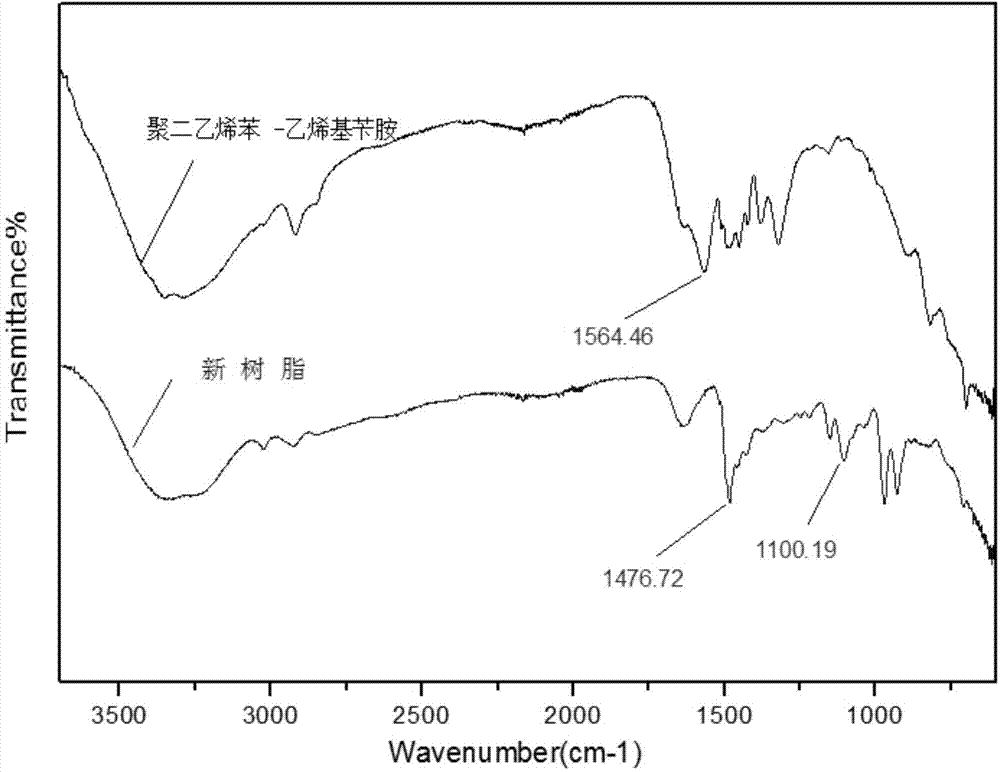

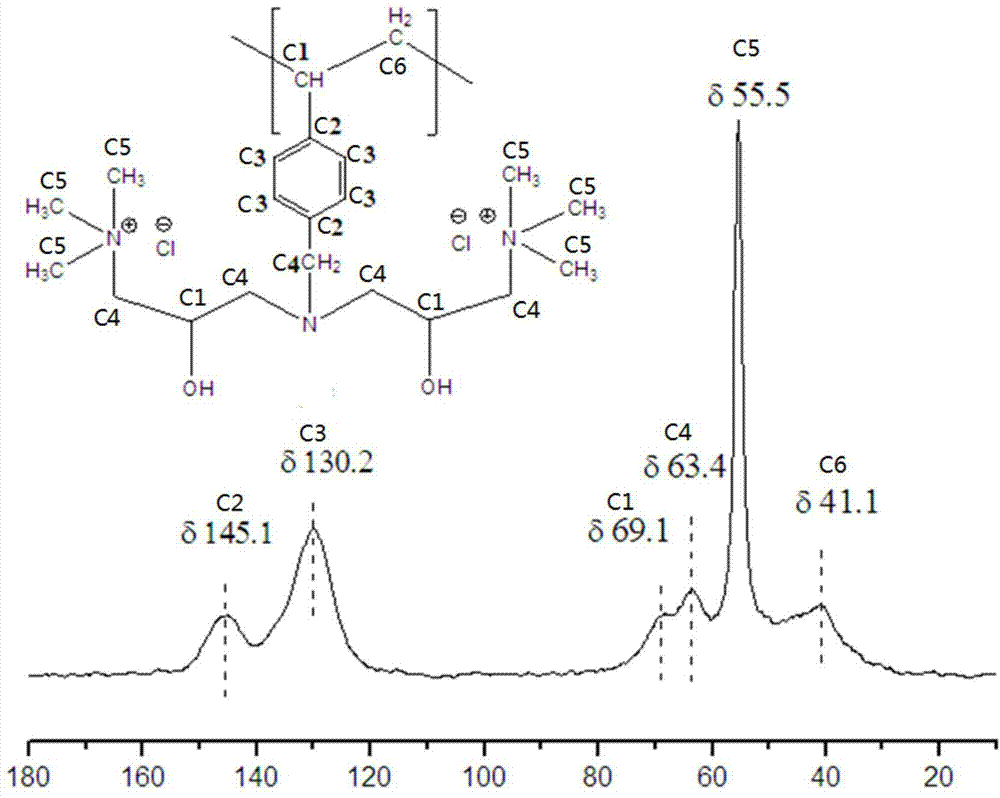

Method used

Image

Examples

Embodiment 1

[0034]A kind of preparation method of high exchange capacity bifunctional group anion exchange resin, its steps are:

[0035] 1) Primary amination reaction

[0036] 5g of chloromethylated polystyrene-divinylbenzene polymer (polymerization degree m is 3000) was swelled at 20°C for 3 hours in a mixed solution of 15 milliliters of absolute ethanol and 2 milliliters of chloroform, and 4 grams of hexamethylene Tetramine, stirred and reacted at 35°C for 6 hours. The polymer was filtered off and washed with ethanol. Concentrated hydrochloric acid with a mass fraction of 37.5% and absolute ethanol are formulated into a mixed acid hydrolysis solution, so that the volume of concentrated hydrochloric acid (ml): the volume of absolute ethanol (ml) = 1:2. Add the polymer to the concentrated hydrochloric acid-absolute ethanol mixed acid hydrolysis solution, so that chloromethylated polystyrene-divinylbenzene polymer (g): mixed acid hydrolysis solution (ml) = 1:4. 35 ° C reaction 2 Hour. ...

Embodiment 2

[0046] A kind of preparation method of high exchange capacity bifunctional group anion exchange resin, its steps are:

[0047] 1) Primary amination reaction

[0048] 5g of chloromethylated polystyrene-divinylbenzene polymer (polymerization degree 3530) was swelled at 20°C for 3 hours in a mixed solution of 15 milliliters of absolute ethanol and 2 milliliters of chloroform, and 4 grams of hexamethylenetetramine was added , and the reaction was stirred at 35 °C for 6 hours. The polymer was filtered off and washed with ethanol. Concentrated hydrochloric acid with a mass fraction of 37.5% and absolute ethanol are formulated into a mixed acid hydrolysis solution, so that the volume of concentrated hydrochloric acid (ml): the volume of absolute ethanol (ml) = 1:2. Add the polymer to the concentrated hydrochloric acid-absolute ethanol mixed acid hydrolysis solution, so that chloromethylated polystyrene-divinylbenzene polymer (g): mixed acid hydrolysis solution (ml) = 1:4. 35 ° C re...

Embodiment 3

[0053] A kind of preparation method of high exchange capacity bifunctional group anion exchange resin, its steps are:

[0054] 1) Primary amination reaction

[0055] 5g of chloromethylated polystyrene-divinylbenzene polymer (polymerization degree 3870) was swelled at 20°C for 3 hours in a mixed solution of 15 milliliters of absolute ethanol and 2 milliliters of chloroform, and 4 grams of hexamethylenetetramine was added , and the reaction was stirred at 35 °C for 6 hours. The polymer was filtered off and washed with ethanol. Concentrated hydrochloric acid with a mass fraction of 37.5% and absolute ethanol are formulated into a mixed acid hydrolysis solution, so that the volume of concentrated hydrochloric acid (ml): the volume of absolute ethanol (ml) = 1:2. Add the polymer to the concentrated hydrochloric acid-absolute ethanol mixed acid hydrolysis solution, so that chloromethylated polystyrene-divinylbenzene polymer (g): mixed acid hydrolysis solution (ml) = 1:4. 35 ° C re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com