Optical fiber refractive index sensor and manufacturing method thereof

A technology of optical fiber refractive index and sensor, which is applied in the measurement of phase influence characteristics, etc., can solve the problems of small air hole size of optical fiber, low nonlinear coefficient of optical fiber, and long length of sensing optical fiber, so as to shorten the length, facilitate filling, and avoid temperature The effect of cross-sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

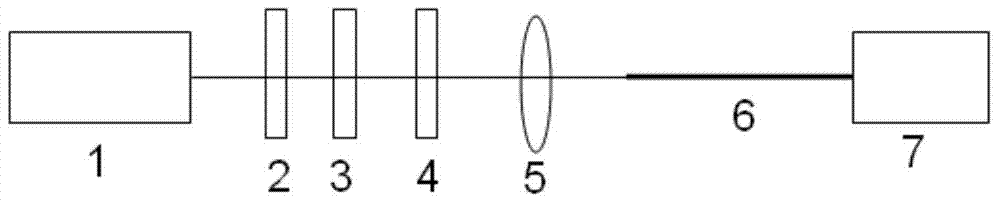

[0019] The embodiment of the present invention introduces as figure 1 The optical fiber refractive index sensor and its manufacturing method are shown to realize the detection of the change of the refractive index of liquid.

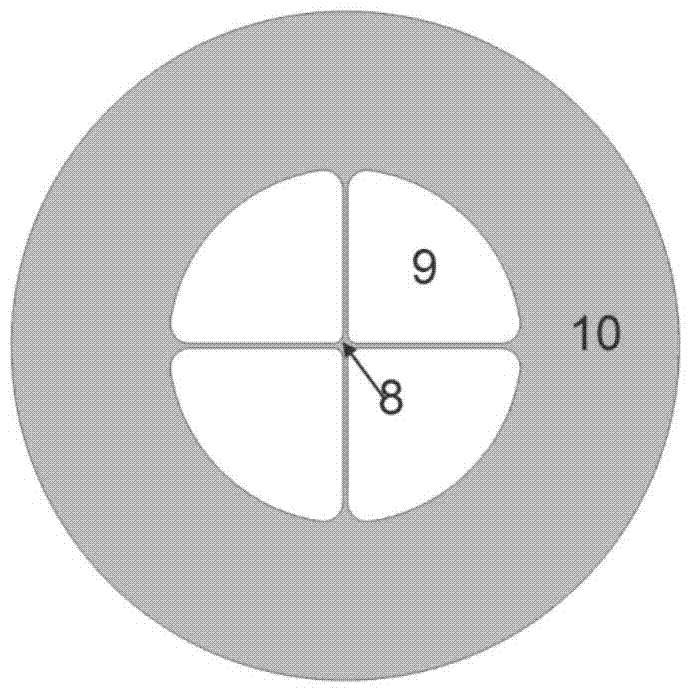

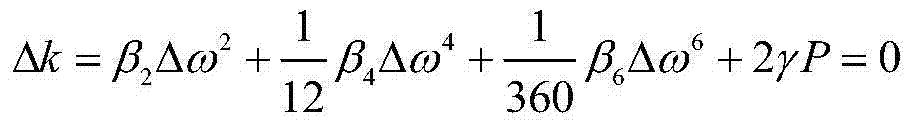

[0020] The optical fiber refractive index sensor provided by the embodiment of the present invention includes a high-power laser, a first half-wave plate, a polarizer, a second half-wave plate, a coupling lens, a suspended core photonic crystal fiber, and a spectrometer along the direction of the optical path; The crystal fiber has a claddin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com