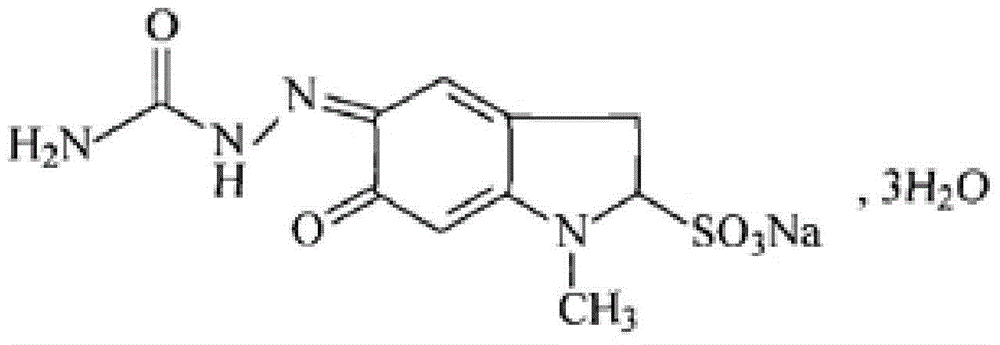

Special ultrafine carbazochrome sodium sulfonate powder freeze-dried preparation and preparation method thereof

A technology of ultrafine powder and sodium carbosulfonate, which is applied in the field of medicine, can solve the problems of large toxic and side effects, small specific surface area, poor stability, etc., and achieve the effect of improving utilization rate, large specific surface area and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dissolve 1000 grams of Kabakol in 3500 grams of water, add 350 grams of sodium bisulfite and 40 grams of vitamin C to react, stir during the reaction, the reaction temperature is 70 ° C, and the reaction time is 50 minutes to obtain a mixed solution. 7.5 g of activated carbon was added to the mixed solution for decolorization, the temperature was maintained at 70° C. for stirring and decolorization for 60 minutes, and after decolorization, it was filtered to obtain a filtrate. Use 5% sodium hydroxide solution to adjust the pH value of the filtrate to 5, lower the temperature of the filtrate to 0°C and let it stand for 8 hours, a large amount of crystals are precipitated, the crystals are separated by filtration, the crystals are washed with water and acetone successively, and then The crystals were vacuum-dried, the vacuum degree of vacuum drying was -0.08Mpa, the drying temperature was 80°C, and the drying time was 6 hours to obtain sodium carbosulfonate with a purity o...

Embodiment 2

[0030] Dissolve 1000 grams of Kabakol in 7000 grams of water, add 800 grams of sodium bisulfite and 200 grams of vitamin C to react, stir during the reaction, the reaction temperature is 75 ° C, and the reaction time is 40 minutes to obtain a mixed solution. 18 grams of activated carbon was added to the mixed solution for decolorization, and the temperature was maintained at 75° C. for stirring and decolorization for 50 minutes. After decolorization, the mixture was filtered to obtain a filtrate. Use 10% sodium hydroxide solution to adjust the pH value of the filtrate to 7, lower the temperature of the filtrate to 2°C and let it stand for 12 hours, a large amount of crystals are precipitated, the crystals are separated by filtration, the crystals are washed with water and acetone successively, and then The crystals were vacuum-dried, the vacuum degree of vacuum drying was -0.09Mpa, the drying temperature was 70°C, and the drying time was 8 hours to obtain sodium carbosulfonate ...

Embodiment 3

[0034] Dissolve 1000 grams of carbacil in 10 kilograms of water, add 1200 grams of sodium bisulfite and 500 grams of vitamin C to react, stir during the reaction, the reaction temperature is 80 ° C, and the reaction time is 30 minutes to obtain a mixed solution. Add 32 grams of activated carbon to the mixed solution for decolorization, maintain the temperature of 80° C. for stirring and decolorization for 40 minutes, and filter after decolorization to obtain a filtrate. Use 20% sodium hydroxide solution to adjust the pH value of the filtrate to 8, lower the temperature of the filtrate to 5°C and let it stand for 16 hours, a large number of crystals are precipitated, the crystals are separated by filtration, the crystals are washed with water and acetone successively, and then The crystals were vacuum-dried, the vacuum degree of vacuum drying was -0.095Mpa, the drying temperature was 60°C, and the drying time was 10 hours to obtain sodium carbosulfonate with a purity of 99.6%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com