Water wiping device for casting hard aluminum alloy

A technology using wipers and hard aluminum alloys, applied in the field of aluminum alloy casting, can solve the problems of poor sealing performance of cooling water, internal stress of supercooled ingots, leakage and splashing of cooling water, etc. Casting success rate and effect of reducing ingot cracking problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

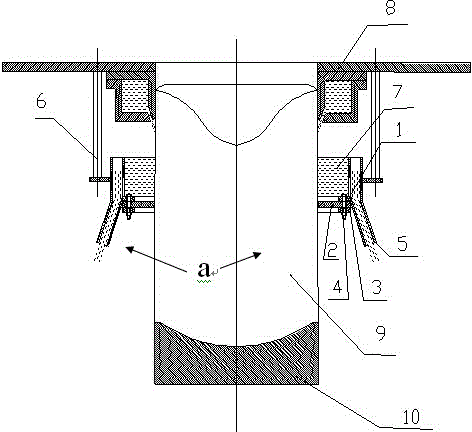

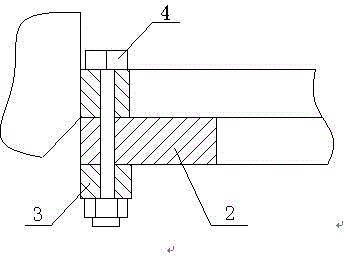

[0022] The invention discloses a wiper for hard aluminum alloy casting. The wiper is installed under the crystallizer 8 and is provided with a wiper ring 2 whose opening shape is the same as the section shape of the ingot 9, including a fixing device 6, a wiper Wiper frame 1, wiper ring 2 and drain port 5; one end of the fixing device 6 is connected to the outer wall of the wiper frame 1, and the other end is connected to the crystallizer 6; the bottom end of the wiper frame 1 is provided with several wiper rings 2. Several drain outlets 5 are arranged on the side wall.

[0023] During casting, a water storage tank 7 is formed between the wiper ring 2, the wiper frame 1 and the ingot 9. Different specifications can be set. For different alloy grades and different ingot 9 specifications, adjust the distance from the wiper to the bottom of the crystallizer 8 to adjust the distance from the water storage tank 7 to the ingot outlet of the crystallizer 8 to adjust the crystallizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com