Basalt fiber reinforced sea sand cement-base composite heat insulation wall plate

A basalt fiber and composite thermal insulation technology, which is applied in the field of sea sand cement-based composite thermal insulation wallboard and its preparation, can solve the problem of not considering the durability of wallboard, low utilization rate of lightweight wallboard material, steel corrosion strength and safety It can alleviate the shortage of river sand resources, light weight, durability and safety guarantee effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Concrete implementation steps of the present invention are as follows:

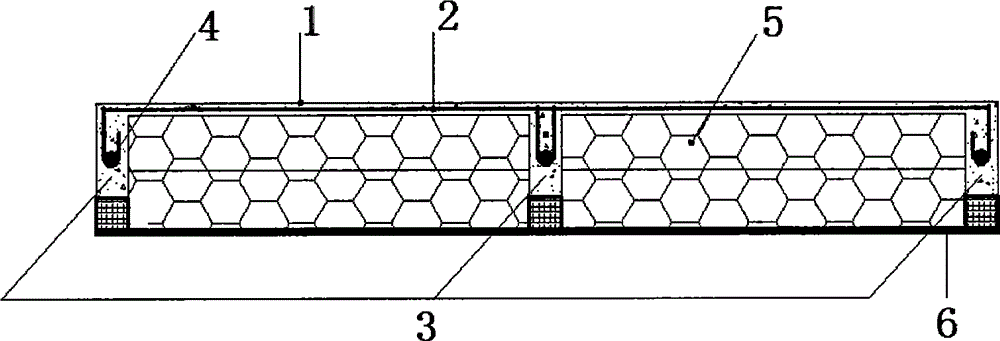

[0025] (1) Make an outer frame with a length of 2m, a width of 1.12m and a height of 0.16m with wooden boards, place a gypsum board of the same length and width on the bottom of the frame, and then place the gypsum board at intervals of 540mm (axis center distance) , with a net distance of 500mm nailing three 40mm×40mm square wooden strips;

[0026] (2) In the nailed frame, 2 layers of 75mm thick polystyrene insulation boards are filled between the two wooden strips to form an embedded thermal insulation board. The size of the rib beam can be determined according to the space left, and the BFRP tendons and BFRP nets bound by the tendons are put into the formwork according to the characteristic steps;

[0027] (3) Then according to the mix ratio in the characteristic step (1), the sea sand cement-based material of the rib beam and the outer panel is poured, and the rib beam is first poured with ord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com