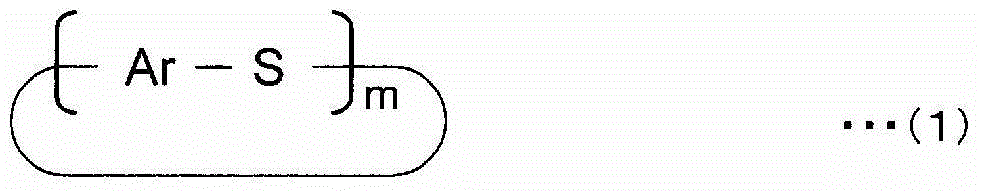

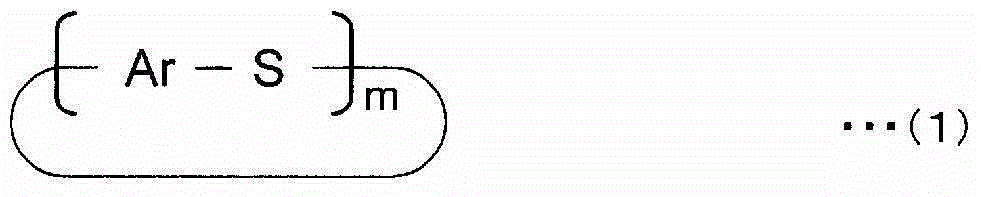

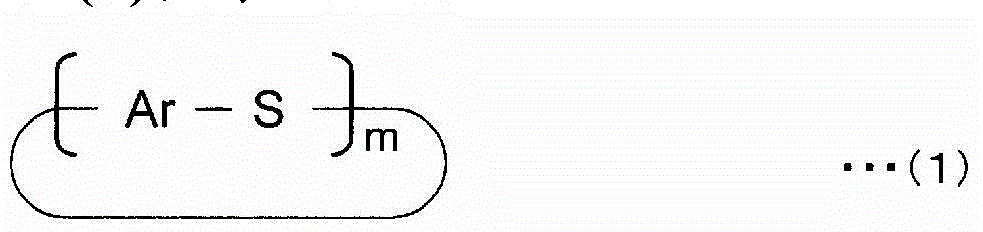

Method for producing polyarylene sulfide, cyclic polyarylene sulfide pellet and method for producing same

A polyarylene sulfide and a technology for a manufacturing method are applied in the field of cyclic polyarylene sulfide particles and their manufacturing to achieve the effects of excellent transferability, molding processability, and low gas properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0192] The present invention will be specifically described below with reference to examples. These examples are illustrative and not limiting.

[0193]

[0194] The molecular weights of PAS and cyclic PAS were calculated by gel permeation chromatography (GPC), which is one of size exclusion chromatography (SEC), in terms of polystyrene, and the number average molecular weight (Mn) and weight average molecular weight (Mw), and the molecular weight distribution was calculated by Mw / Mn calculation. The measurement conditions of GPC are shown below.

[0195] Device: Senshu Science SSC-7100

[0196] Column name: Showa Denko shodex UT806M

[0197] Eluent: 1-Chloronaphthalene

[0198] Detector: Differential Refractive Index Detector

[0199] Column temperature: 210°C

[0200] Pre-heating bath temperature: 250°C

[0201] Pump thermostat temperature: 50°C

[0202] Detector temperature: 210°C

[0203] Flow: 1.0mL / min

[0204] Sample injection volume: 300 µL (slurry state: a...

reference example 1

[0230] Add 1.648kg of 48% by weight aqueous solution of sodium hydrosulfide (sodium hydrosulfide 0.791kg (14.1 mole)), 1.225kg of 48% by weight aqueous solution of sodium hydroxide (sodium hydroxide 0.588 kg (14.7 moles)), N-methyl-2-pyrrolidone (NMP) 35 L, and p-dichlorobenzene (p-DCB) 2.278 kg (15.5 moles).

[0231] The reaction vessel was sealed under nitrogen at room temperature and normal pressure, and then the temperature was raised from room temperature to 200° C. over 25 minutes while stirring at 400 rpm. Next, it heated up to 250 degreeC over 35 minutes, and was made to react at 250 degreeC for 2 hours. Next, while maintaining the internal temperature at 250° C., the extraction valve was slowly opened, and 26.6 kg of the solvent was distilled off over 40 minutes. After the solvent was distilled off, the autoclave was cooled to around room temperature, and the contents were collected.

[0232] The recovered content was heated and stirred under nitrogen gas so that th...

reference example 2

[0234] Except having made the p-DCB of a raw material 2.116 kg (14.4 mol), and having made the solid-liquid separation temperature 50 degreeC, it carried out similarly to the reference example 1, and obtained the dry solid powder. From the analysis results of infrared absorption spectrum and high-performance liquid chromatography of the obtained dried solid, it was found that 85% by weight of cyclic polyphenylene sulfide was contained. The weight loss rate ΔWr(a) when heated at 200°C to 330°C was 1.439%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com