Preparation method for Ag3PO4/TiOF2 composite photo-catalyst

A technology of catalyst and composite light, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve high photocatalytic activity, good stability, and simple production equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

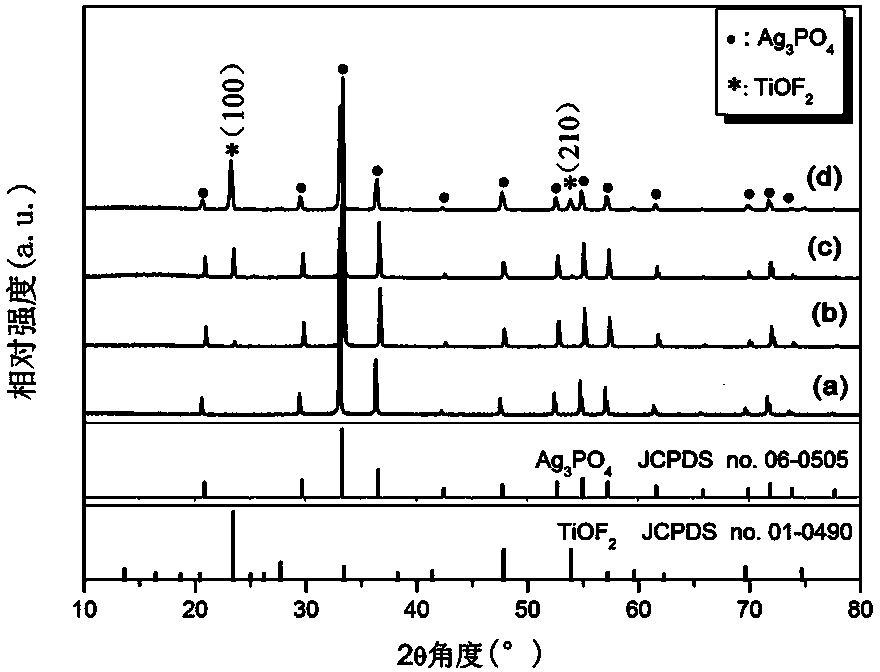

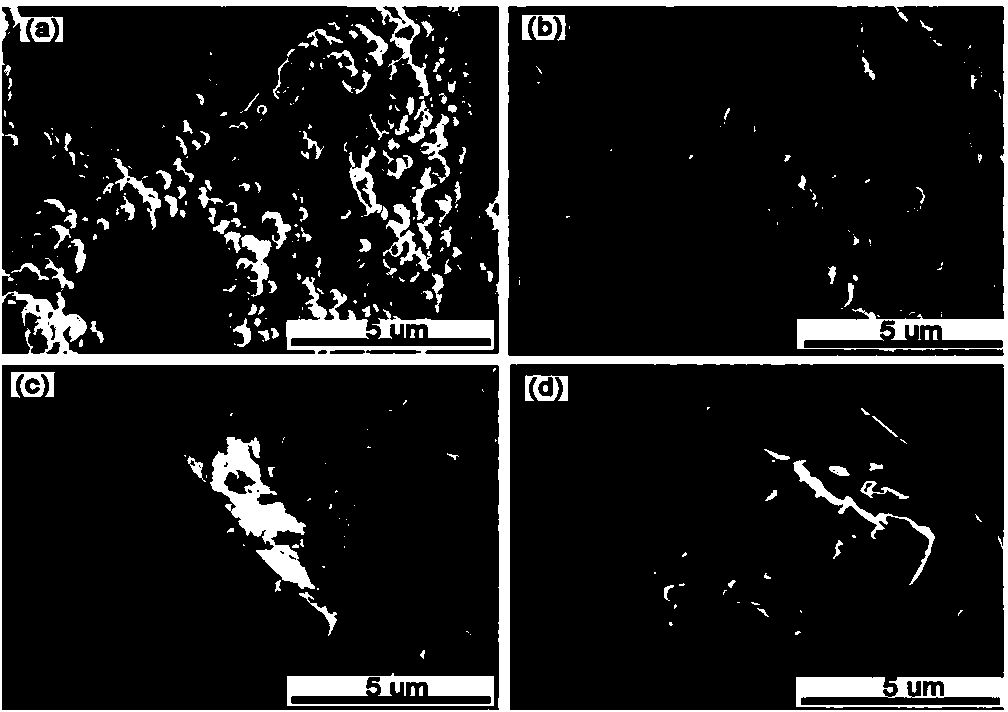

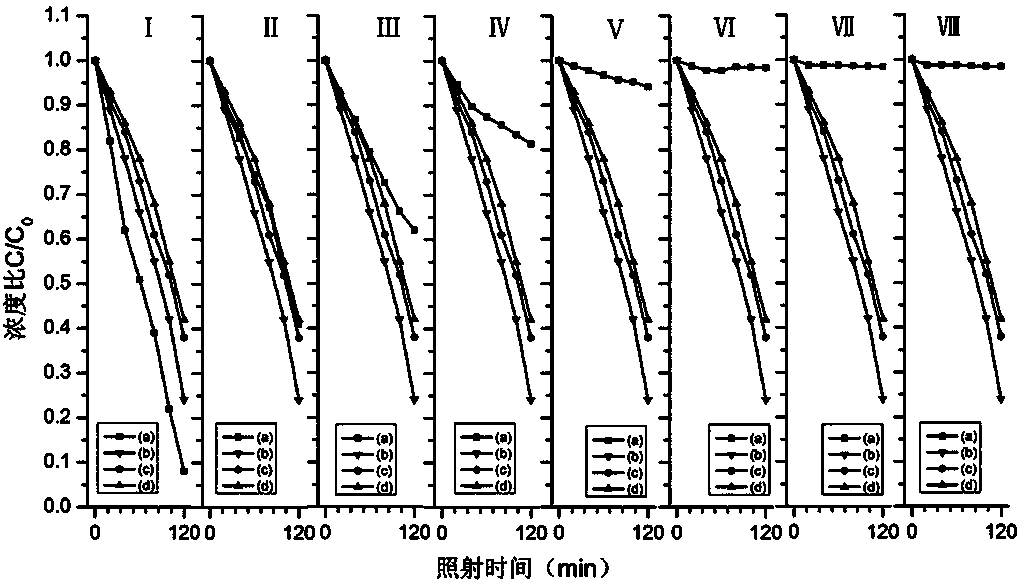

[0015] Preparation of Ag 3 PO 4 with TiOF 2 Ag with a molar ratio of 1:0.2 3 PO 4 / TiOF 2 composite photocatalyst.

[0016] Synthesis of TiOF by Hydrothermal Method 2 , weighed 0.45g of TiF 4 , into the lining of the hydrothermal reactor, and then add 20mL of n-butanol, in TiF 4 When it is not completely dissolved, quickly add 0.2mL of hydrofluoric acid with a mass percentage of 48%. After the reaction kettle is sealed and covered, it is placed in a blast drying oven, and it is hydrothermally reacted at 200°C for 6 hours. TiOF was obtained by centrifuging three times with water and ethanol 2 Sample; Weigh 0.12gTiOF 2 sample, ultrasonically dispersed in deionized water for 30 minutes to obtain TiOF 2 Suspension; then weigh 1.0g silver acetate and add to TiOF under stirring condition 2 In the suspension, add Na at a concentration of 0.15mol / L dropwise 2 HPO 4 Solution 13.5mL, a light yellow precipitate was formed, and was centrifuged and washed 3 times with deionize...

Embodiment 2

[0019] Preparation of Ag 3 PO 4 with TiOF 2 Ag at a molar ratio of 1:1 3 PO 4 / TiOF 2 composite photocatalyst.

[0020] Synthesis of TiOF by Hydrothermal Method 2 , weighed 0.45g of TiF 4 , into the lining of the hydrothermal reactor, and then add 20mL of n-butanol, in TiF 4 When it is not completely dissolved, quickly add 0.2mL of hydrofluoric acid with a mass percentage of 48%. After the reaction kettle is sealed and covered, it is placed in a blast drying oven, and it is hydrothermally reacted at 200°C for 8 hours. TiOF was obtained by centrifuging three times with water and ethanol 2 Sample; Weigh 0.19gTiOF 2 The sample was ultrasonically dispersed in deionized water for 20 minutes to obtain TiOF 2 Suspension; then weigh 0.32g of silver acetate and add to TiOF under stirring condition 2 In the suspension, add Na at a concentration of 0.15mol / L dropwise 2 HPO 4 Solution 4.2mL, a light yellow precipitate was formed, and was centrifuged and washed 3 times with de...

Embodiment 3

[0023] Preparation of Ag 3 PO 4 with TiOF 2 Ag with a molar ratio of 1:5 3 PO 4 / TiOF 2 composite photocatalyst.

[0024] Synthesis of TiOF by Hydrothermal Method 2 , weighed 0.45g of TiF 4 , into the lining of the hydrothermal reactor, and then add 20mL of n-butanol, in TiF 4 When it is not completely dissolved, quickly add 0.2mL of hydrofluoric acid with a mass percentage of 48%, seal and cover the reaction kettle, put it in a blast drying oven, and conduct a hydrothermal reaction at 200°C for 5 hours. TiOF was obtained by centrifuging three times with water and ethanol 2 Sample; Weigh 0.62gTiOF 2 The sample was ultrasonically dispersed in deionized water for 60 minutes to obtain TiOF 2 Suspension; then weigh 0.20g of silver acetate and add to TiOF under stirring condition 2 In the suspension, add Na at a concentration of 0.15mol / L dropwise 2 HPO 4 Solution 2.7mL, a light yellow precipitate was formed, and was centrifuged and washed 3 times with deionized water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com