Obstruction film and manufacturing method thereof

A production method and barrier film technology, applied in semiconductor/solid-state device manufacturing, ion implantation plating, gaseous chemical plating, etc., can solve the problem that the service life of electronic components cannot meet the design requirements, increase production time and raw material consumption, barrier Low film barrier performance and other problems, to achieve the effect of low production cost, low water vapor transmission rate, and improve barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

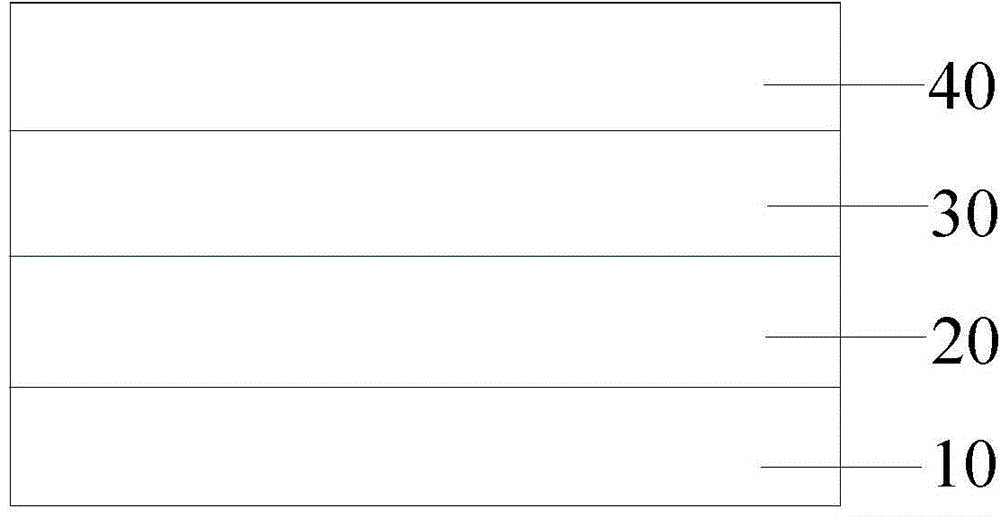

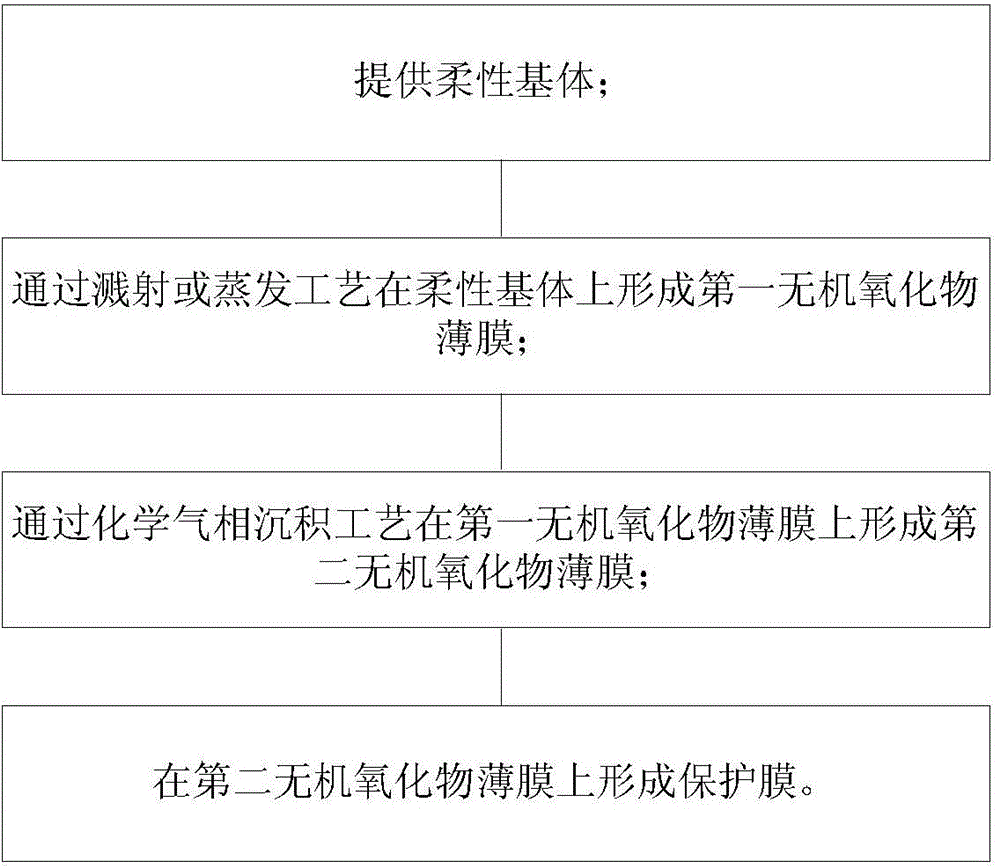

[0046] This embodiment provides a barrier film and a manufacturing method thereof. Wherein, the preparation method includes the following steps:

[0047] providing a flexible substrate composed of polyethylene terephthalate (PET), and coating the surface of the flexible substrate with a hardened coating composed of polyacrylate resin, wherein the thickness of the flexible substrate is 125 μm, and Through AFM detection, it can be seen that the surface roughness of the hardened coating is 1.24nm;

[0048] Forming a first inorganic oxide film on a flexible substrate by a sputtering process, wherein the material of the first inorganic oxide film is indium tin oxide (ITO), and the thickness of the first inorganic oxide film is 20nm;

[0049] A second inorganic oxide film is formed on the first inorganic oxide film by a chemical vapor deposition process, wherein the material of the second inorganic oxide film is Al 2 o 3 , the thickness of the second inorganic oxide film is 10 nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com