Amino-modified persimmon tannin adsorbent and its preparation method and application

An adsorbent and persimmon technology, which is applied in the field of effective extraction of scattered metals and preparation of green adsorbents, can solve problems such as waste of resources, and achieve the effects of reduced processing costs, high molybdenum-rhenium separation effect, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

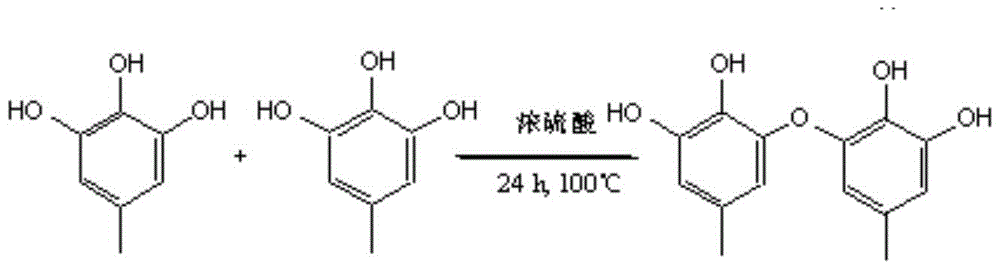

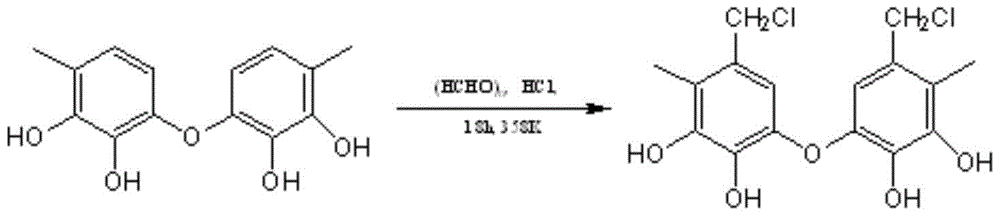

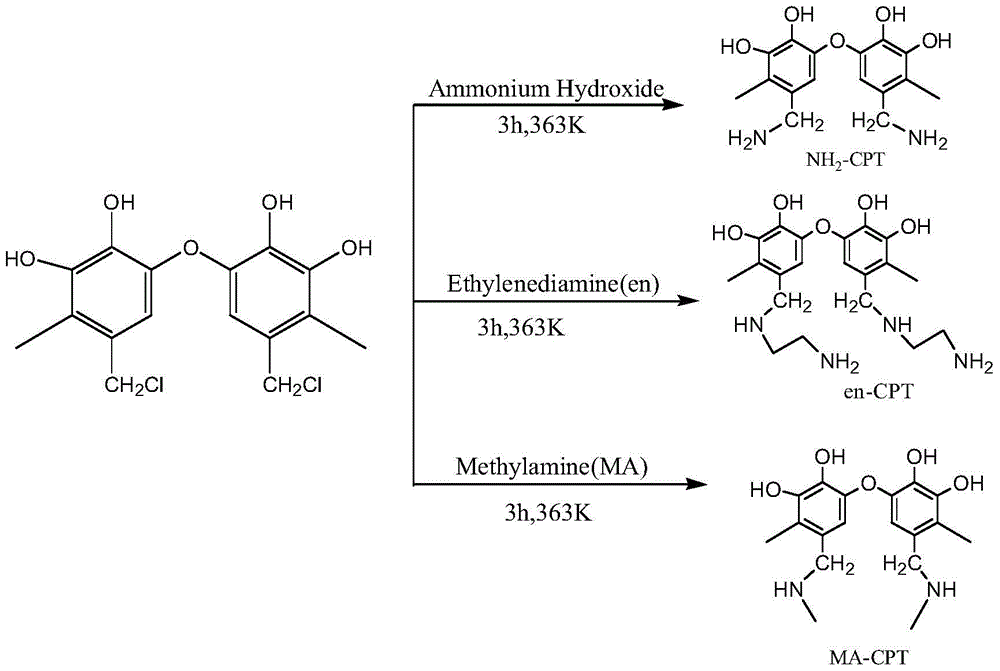

[0022] Example 1 Preparation of Ammonia Modified Persimmon Tannin Adsorbent

[0023] Put 10 g of dried persimmon tannin (PT) powder in a round bottom flask, add 30 mL of 13.5 mol / L sulfuric acid, acidify at a temperature of 90-100° C. for 6 hours, and continuously stir to make it dehydrated and cross-linked. After the reaction is completed, it is suction filtered, washed with deionized water to neutrality, and dried to obtain a black powdery product (CPT). Then add 100mL 6mol / L HCl, 5g paraformaldehyde, 358K oil bath heating for 18h, stirring constantly, after the reaction is completed, suction filtration, wash with deionized water to neutrality, dry at 50℃ for 3h to obtain a black powdery product (Cl- CPT). Put the obtained black powdery product (Cl-CPT) in a 500mL round bottom flask, add 50mL 50% ammonia water, 10mL 37% formaldehyde to it, keep the temperature at 363K, and keep stirring for 3h. After the reaction is complete, filter with suction. Wash with deionized water to ...

Embodiment 2

[0025] Example 2 Preparation of ethylenediamine modified persimmon tannin adsorbent

[0026] The preparation method is the same as that in Example 1, except that the ammonia water is replaced with ethylenediamine. The ethylenediamine modified persimmon tannin adsorbent en-CPT was obtained. The yield is about 90%.

[0027] Elemental analysis data test results: the nitrogen content of the adsorbent is 9.09%, which proves that the obtained product is an adsorbent modified with ethylenediamine.

Embodiment 3

[0028] Example 3 Preparation of persimmon tannin adsorbent modified by methylamine

[0029] The preparation method is the same as in Example 1, except that the ammonia water is replaced with methylamine. The methylamine modified persimmon tannin adsorbent MA-CPT was obtained. The yield is about 90%.

[0030] Elemental analysis data test results: the nitrogen content of the adsorbent is 6.08%, which proves that the obtained product is a methylamine modified adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com