Method for producing dimethyl cyclosiloxane in non-halogenation direct continuous mode

A dimethylcyclosiloxane, non-halogenated technology, applied in the direction of silicon organic compounds, can solve problems such as unstable product batches, inability to realize automatic control, and reduced economies of scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

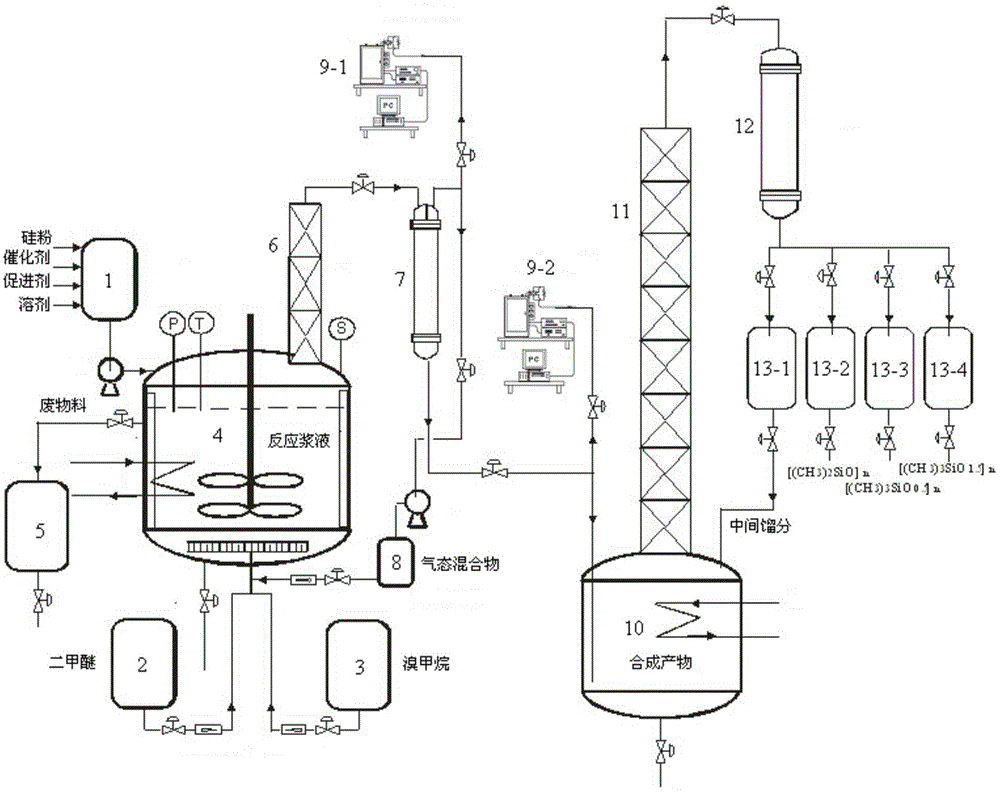

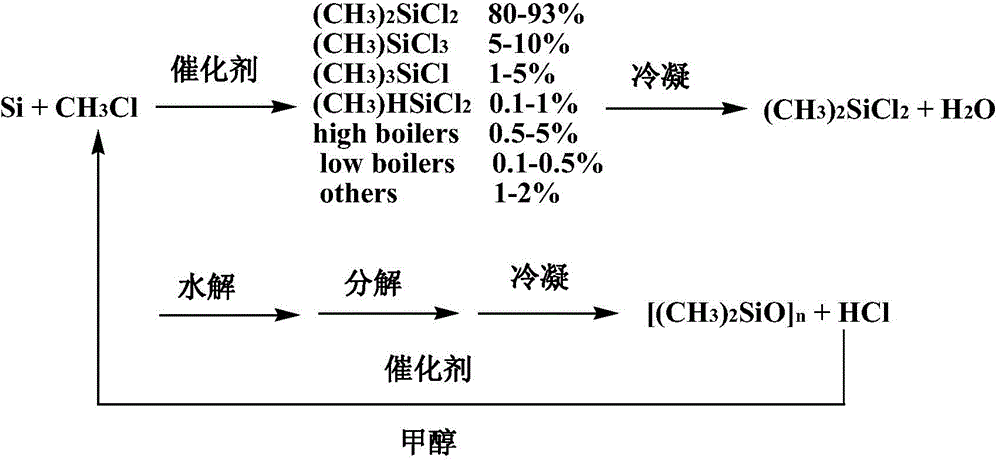

Method used

Image

Examples

Embodiment 1

[0036] Pretreatment of raw materials: dry pretreatment of dimethyl ether and methyl bromide, add a section of molecular sieve tube in the outlet channel of the storage tank of dimethyl ether and methyl bromide, that is, before entering the reactor, to remove the trace amount contained in the raw materials of dimethyl ether and methyl bromide Water; pretreatment of silicon powder, weigh hydrofluoric acid solution with a weight ratio of 5:1 and 150 μm silicon powder, stir at room temperature for 1 hour, filter, fully wash with absolute ethanol, and vacuum dry at 80°C for 5 Hours, remove the SiO on the surface layer of silicon powder 2 , standby;

[0037] Activation treatment of silicon powder: Mix CuCl, ZnO and Sn in a weight ratio of 50:1:1 to obtain a catalyst mixture, then fully mix the catalyst mixture with the above silicon powder in a weight ratio of 2:100, and treat the mixture with a microwave oven for 3 Minutes, get activated silicon powder;

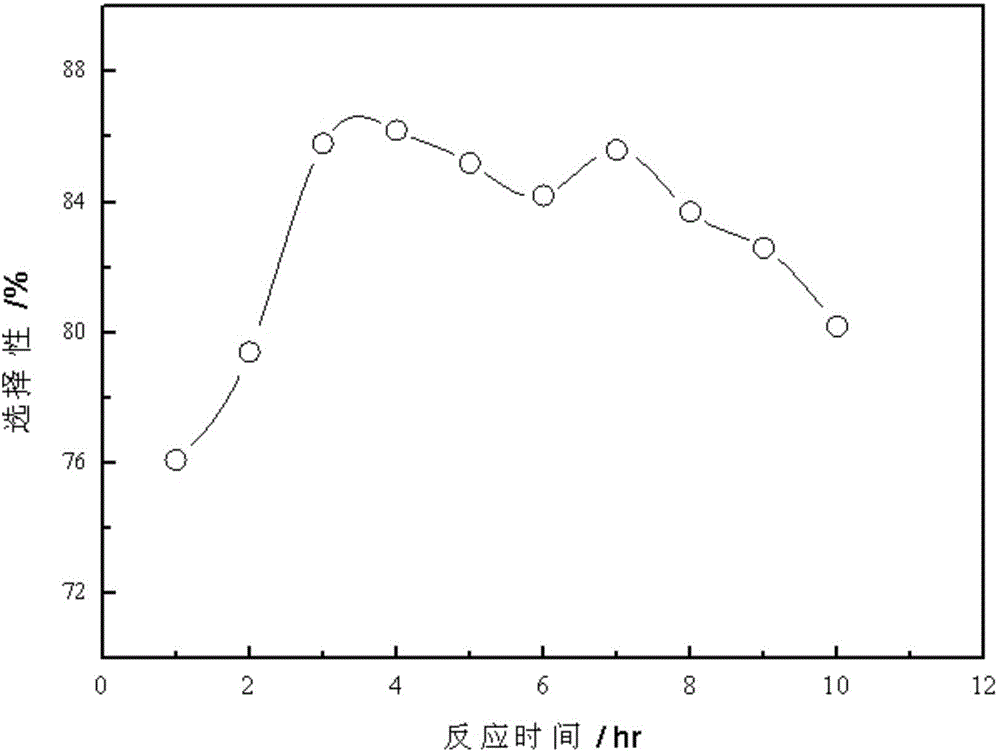

[0038] Synthesis and sep...

Embodiment 2

[0043] Pretreatment of raw materials: dry pretreatment of dimethyl ether and methyl bromide, in the outlet channel of the storage tank of dimethyl ether and methyl bromide, add a section of molecular sieve tube before entering the reactor, to remove trace water contained in the raw materials of dimethyl ether and methyl bromide ; For the pretreatment of silicon powder, weigh a hydrofluoric acid solution with a weight ratio of 5:1 and 120 μm silicon powder, stir at room temperature for 1 hour, filter, wash thoroughly with absolute ethanol, and dry in vacuum at 80°C for 5 hours , to remove the SiO on the surface layer of silicon powder 2 , standby;

[0044] Activation treatment of silicon powder: Mix CuCl and ZnO at a weight ratio of 50:1 to obtain a catalyst mixture, then fully mix the catalyst mixture with the above-mentioned silicon powder at a weight ratio of 2:100, and then sinter the mixture under vacuum at 120°C for 3 hours. Get activated silicon powder;

[0045] Synthe...

Embodiment 3

[0049] Pretreatment of raw materials: dry pretreatment of dimethyl ether and methyl bromide, in the outlet channel of the storage tank of dimethyl ether and methyl bromide, add a section of molecular sieve tube before entering the reactor, to remove trace water contained in the raw materials of dimethyl ether and methyl bromide ; Pretreatment of silicon powder, weigh hydrofluoric acid solution with a weight ratio of 5:1 and 200 μm silicon powder, stir at room temperature for 1.5 hours, filter, fully wash with absolute ethanol, and vacuum dry at 80°C for 5 hours , to remove the SiO on the surface layer of silicon powder 2 , standby;

[0050] Activation treatment: Mix CuCl and Sn at a weight ratio of 50:1 to obtain a catalyst mixture, then fully mix the catalyst mixture with the above-mentioned silicon powder at a weight ratio of 2:100, and treat the mixture in a microwave oven for 5 minutes to obtain activated silicon powder;

[0051] Synthesis of dimethylcyclosiloxane: After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com