Method for preparing graphene-polyimide conductive black film

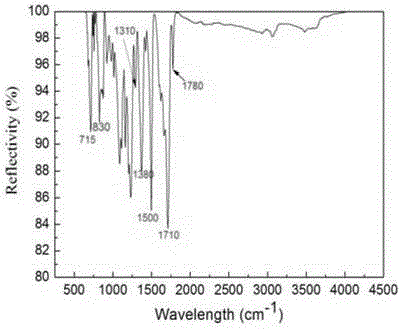

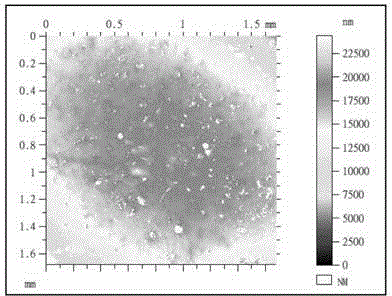

A polyimide and graphene technology, which is applied in the field of graphene-polyimide conductive black film preparation, can solve the problems of less research on polyimide black film, affecting the conductivity and high light transmittance of composite films, etc. , to achieve the effect of low cost, smooth surface and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferably, the preparation method of the present invention comprises the following steps:

[0016] 1. Expandable graphite for secondary expansion

[0017] Weigh an appropriate amount of flake graphite, use potassium permanganate as an oxidant, concentrated sulfuric acid as an intercalation agent, bathe in a water bath at 20°C-60°C, stir intermittently for 30-120min, wash with dilute hydrochloric acid (10%-20%) and deionized water to medium properties, filtered and dried to obtain expandable graphite. Take the dried expandable graphite and place it in a microwave oven for expansion, with a power of 10KW, a temperature of 500°C-1000°C, and an expansion time of 10-30s to obtain expanded graphite. The expanded graphite is secondarily expanded by the above-mentioned method;

[0018] 2. Preparation of graphene and black filler dispersion

[0019] Add 30-90ml of N,N-dimethylformamide or N,N-dimethylacetamide into a 250mL three-necked flask, and add an appropriate amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com