Preparation method of super-hydrophobic magnetic sponge

A super-hydrophobic and super-hydrophobic technology is applied in the field of preparation of super-hydrophobic magnetic sponges, which can solve the problems of difficulty in recycling, and achieve the effects of easy operation, simple method and improved material utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

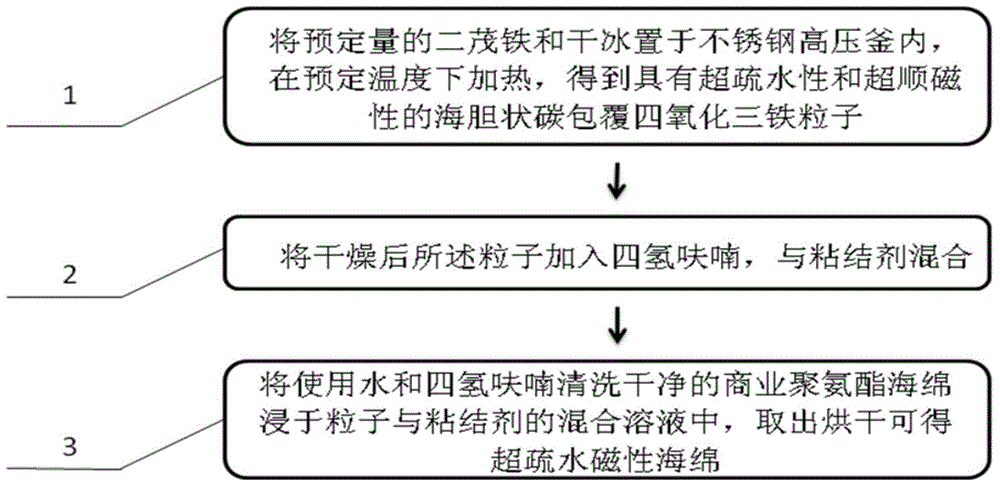

[0019] Embodiment 1. Preparation of sea urchin-like carbon-coated ferric oxide particles

[0020] 2g of dry ferrocene was placed in a stainless steel autoclave with a volume of 20ml, and 12g of dry ice was added. After tightening the kettle, heat at 400°C for 10h. After the reaction, the autoclave was opened to obtain a black product. The product was washed with alcohol three times and dried at 60°C to obtain superhydrophobic and superparamagnetic sea urchin-like carbon-coated ferric oxide particles.

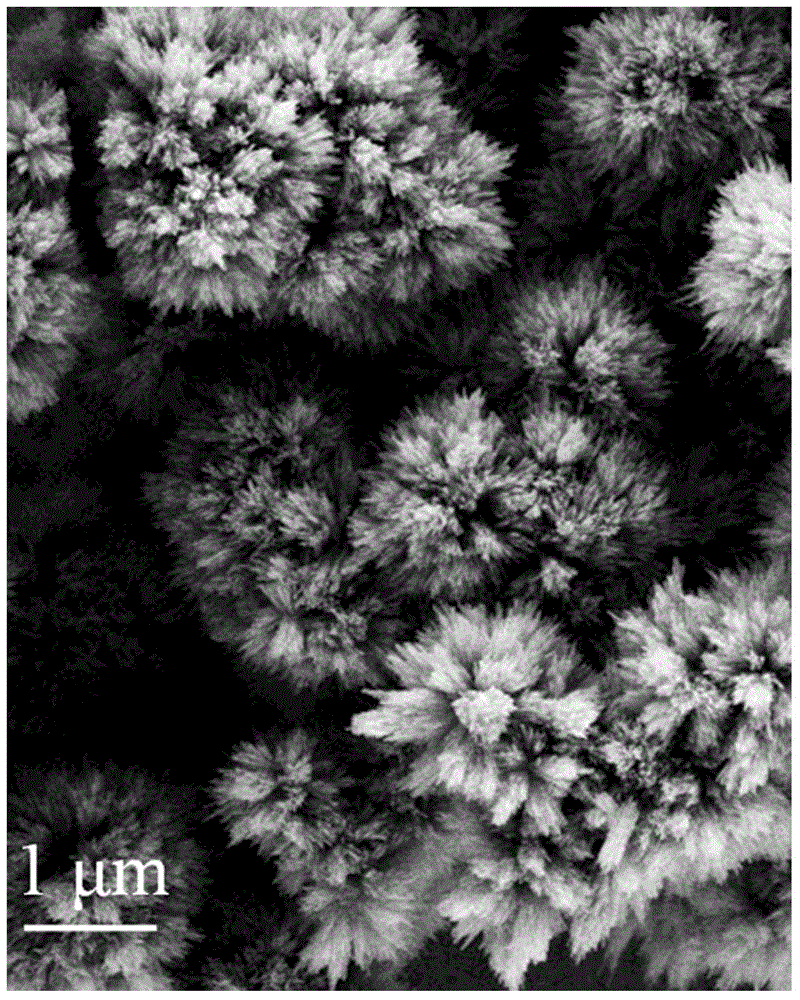

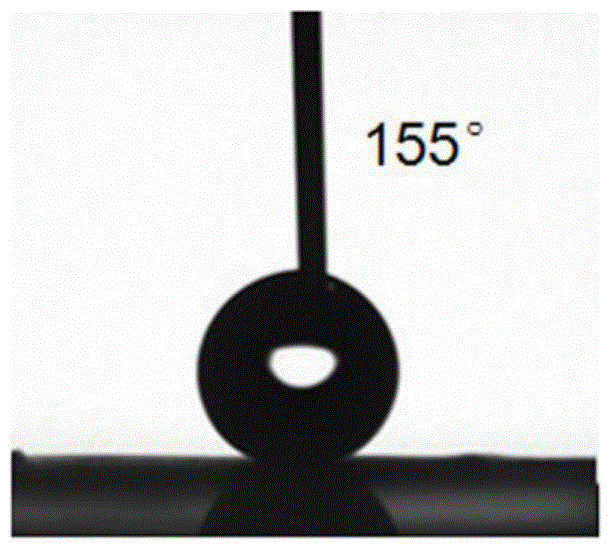

[0021] figure 2 It is a scanning electron microscope photo of the product. It can be seen that the particles are composed of many nanorods gathered together, showing a fractal sea urchin-like micro-nano structure. like image 3 As shown, the contact angle between the particle surface and water is 155° by the contact angle tester. like Figure 4 As shown, the particle has superparamagnetism measured by a vibrating sample magnetometer.

Embodiment 2

[0022] Embodiment 2. Preparation of sea urchin-like carbon-coated ferric oxide particles

[0023] 3 g of dry ferrocene was placed in a stainless steel autoclave with a volume of 20 ml, and 14 g of dry ice was added. After tightening the kettle, heat at 400°C for 12h. After the reaction, the autoclave was opened to obtain a black product. The product was washed with alcohol three times and dried at 60°C to obtain superhydrophobic and superparamagnetic sea urchin-like carbon-coated ferric oxide particles.

Embodiment 3

[0024] Embodiment 3. prepare superhydrophobic magnetic sponge

[0025] A piece of commercial polyurethane sponge (both length, width and height are 1 cm) was washed several times with water and tetrahydrofuran, and then dried at 60°C. Take 0.5 g of the sea urchin-like carbon-coated ferric oxide particles prepared according to Example 1, disperse them in 10 ml of tetraoxyfuran, and ultrasonicate for 15 min. Then add 0.1 of the polydimethylsiloxane A component to the solution, and then sonicate for 30 minutes. Then take 0.01 of the B component of polydimethylsiloxane and disperse it in 10ml of tetrahydrofuran and sonicate for 30min. After sonication is complete, the two solutions are mixed together, and the dried sponge is dipped into the mixed solution. After coating, the modified sponge was dried at 60°C.

[0026] like Figure 5 and Image 6 As shown, obtained by the contact angle tester test, the sponge contact angles before and after modification are 112° and 141° respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com