Preparation method of ultraviolet-curing activator based on ink-jet printing technology and process for carrying out activation treatment by using activator

A technology of inkjet printing and activation treatment, applied in metal material coating process, application, ink, etc., can solve the problems of many steps and unstable treatment effect, and achieve strong adhesion, fast UV curing rate and easy production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

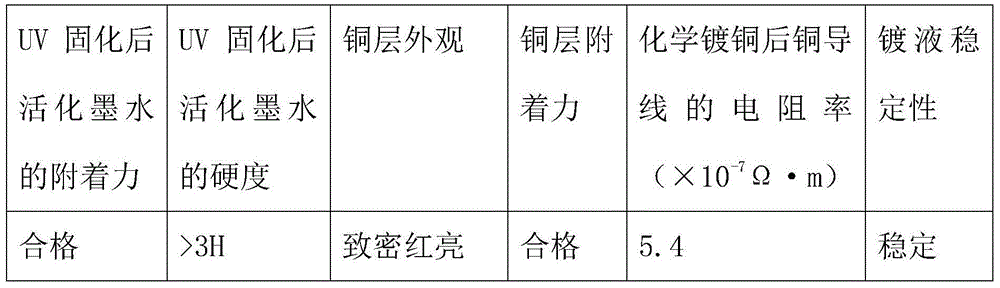

Embodiment 1

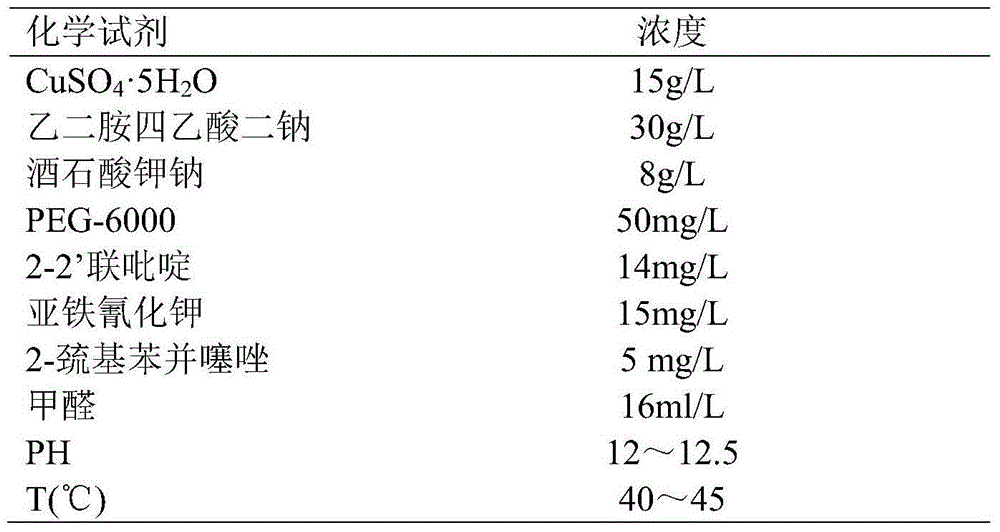

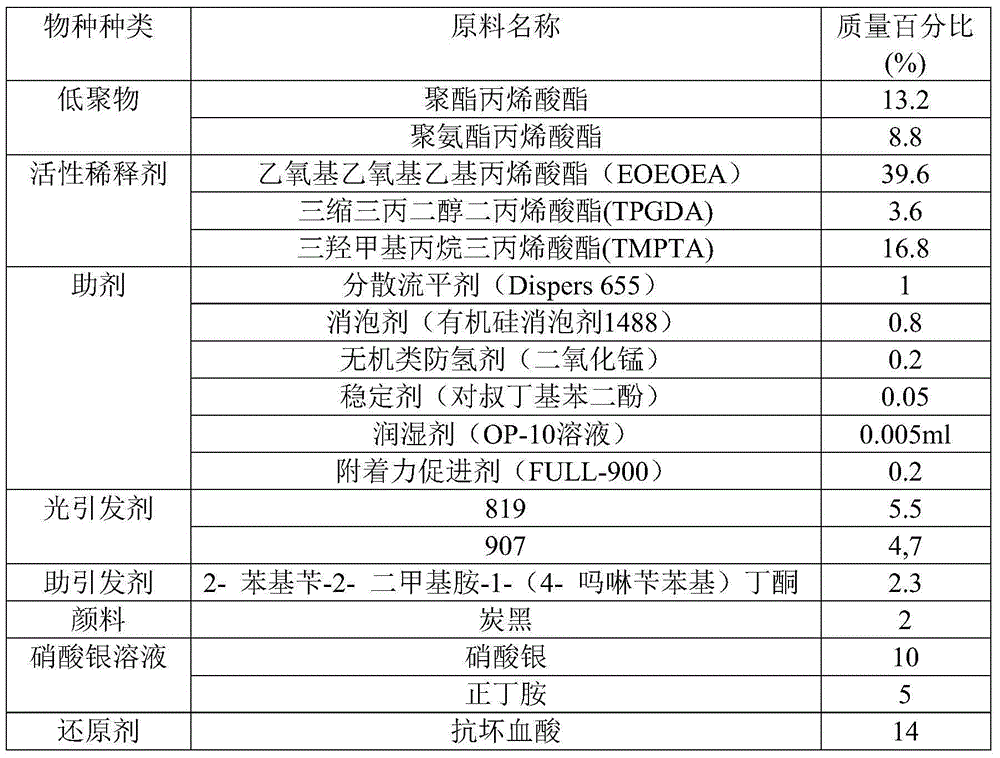

[0050] Table 2 prepares the raw materials and proportioning of black UV photocurable inkjet ink

[0051]

[0052] According to the formula and dosage of Table 2, prepare UV curable inkjet ink:

[0053] (1) Preparation of color paste: Weigh 10g carbon black, 10g polyurethane acrylate and mix and grind 20 times with SM65 three-roll mill to obtain pigment resin dispersion system; 20g pigment resin dispersion, 80g mixed monomer (EOEOEA:TPGDA : TMPTA=11:1:5), 1g of dispersing and leveling agent was stirred at room temperature for 2 hours with a T80basic type homogenizer at a speed of 3000r / min, and then filtered through a 0.45 micron membrane to obtain a carbon black slurry.

[0054] (2) Preparation of film-forming phase:

[0055] First dissolve 10.2g of mixed photoinitiator (819:907=5.5:4.7) and 2.3g of active amine co-initiator with 12g of monomer, then add 13.2g of polyester acrylate, 8.8g of polyurethane acrylate, and 20g of carbon black The slurry, 1g of dispersing and le...

Embodiment 2

[0073] Present embodiment is on the basis of embodiment 1, changes the kind of pigment, and selects suitable photoinitiator for use, other remains unchanged.

[0074]

[0075] It can be seen from the above table that in order to obtain good conductivity after electroless plating, carbon black is preferred.

Embodiment 3

[0077] This embodiment is on the basis of embodiment 1, changes the consumption of carbon black, other remains unchanged.

[0078]

[0079] Note: The peeling of the copper layer causes the line to be disconnected, so the resistance is infinite.

[0080] It can be seen from the above table that in order to obtain good conductivity after electroless plating, the preferred proportion of black color paste is 3%-7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com