Modified acrylate high temperature-resistant anaerobic adhesive and preparation method thereof

An acrylate, high temperature resistant technology, applied in the field of high temperature resistant anaerobic adhesive and its preparation, can solve the problems of increased strength, difficulty in disassembly, etc., and achieve the effects of improving heat resistance, easy disassembly and maintenance, and good adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

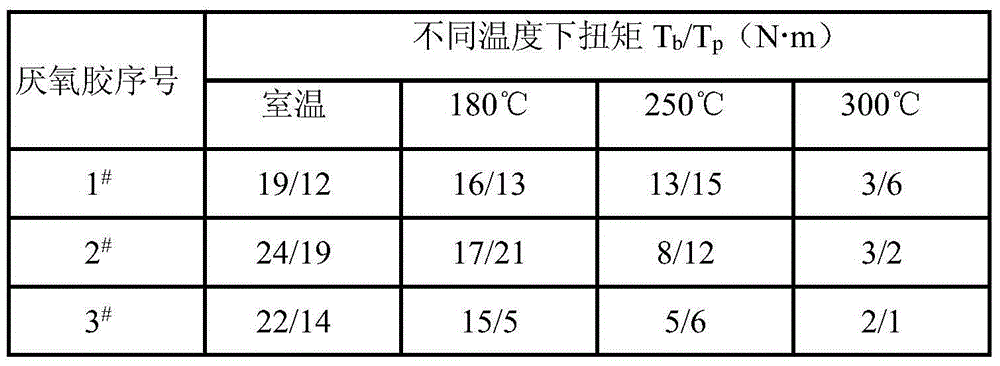

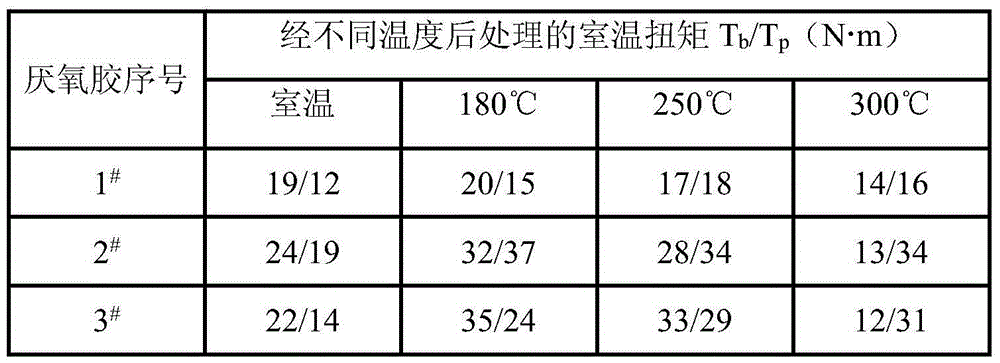

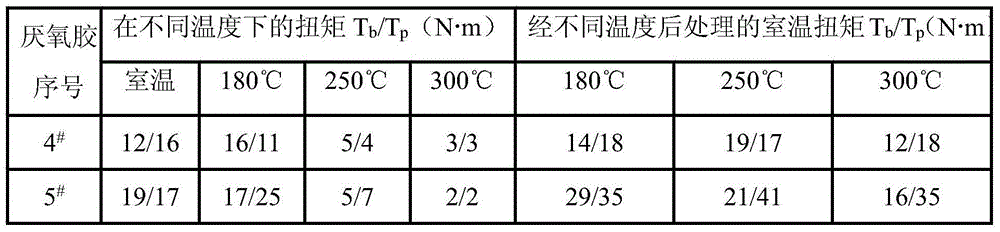

Examples

specific Embodiment approach 1

[0030] Specific embodiment one: In this embodiment, a modified acrylate high-temperature anaerobic adhesive consists of 100 parts by weight of anaerobic acrylate monomer, 0.01-5 parts of stabilizer, 5-70 parts of heat-resistant resin, 0.1 ~10 parts of accelerator, 0.1~10 parts of co-accelerator, 20~70 parts of silicon-titanium modified resin and 1~10 parts of initiator;

[0031] The anaerobic acrylate monomer is ethylene glycol (meth)acrylate, triethylene glycol di(meth)acrylate, tetraethylene glycol di(meth)acrylate, polyethylene Glycol Di(meth)acrylate, Ethoxylated Bisphenol A Di(meth)acrylate, Alkyl(meth)acrylate, Trimethylolpropane Tri(meth)acrylate, Ethoxylated Trihydroxy Methylpropane Tri(meth)acrylate, Hydroxyethyl(meth)acrylate, Hydroxypropyl(meth)acrylate, 2-Ethylhexyl(meth)acrylate, Silicone acrylate, Monomethylol One or one of phenol monoacrylate, dimethylol phenol diacrylate, trimethylol phenol triacrylate, polyurethane (meth)acrylate and allyloxybenzene-containin...

specific Embodiment approach 2

[0040] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: by weight, 100 parts of anaerobic acrylate monomer, 2 to 5 parts of stabilizer, 10 to 40 parts of heat-resistant resin, 4 to 8 parts It is prepared by 1 part of accelerator, 4-8 parts of co-accelerator, 30-60 parts of silicon-titanium modified resin and 4-8 parts of initiator. Others are the same as the first embodiment.

specific Embodiment approach 3

[0041] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: by weight, 100 parts of anaerobic acrylate monomer, 3 parts of stabilizer, 20 parts of heat-resistant resin, 5 parts of accelerator, It is made of 5 parts of co-accelerator, 50 parts of silicon titanium modified resin and 5 parts of initiator. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com