Device for preparing gradient nanometer layer on surface of metal material by using rolling deformation

A metal material and surface gradient technology, which is applied in the field of devices for preparing gradient nano-layers on the surface of metal materials by rolling deformation, can solve the problem of difficult to realize the controllable preparation of surface gradient nano-crystalline layers, difficult to apply engineering practice, and the thickness of surface nano-layers Insufficiency and other problems, to achieve the effect of uniform deformation, controllable preparation and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

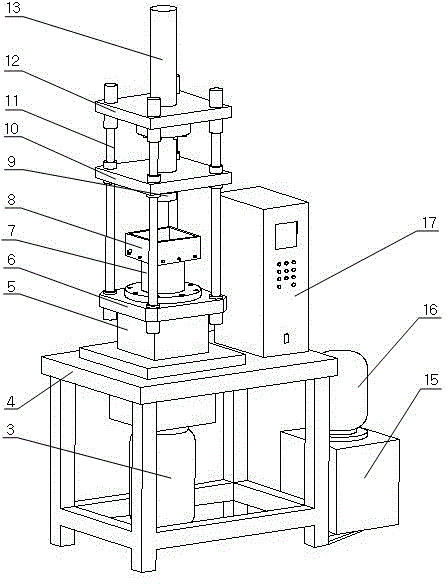

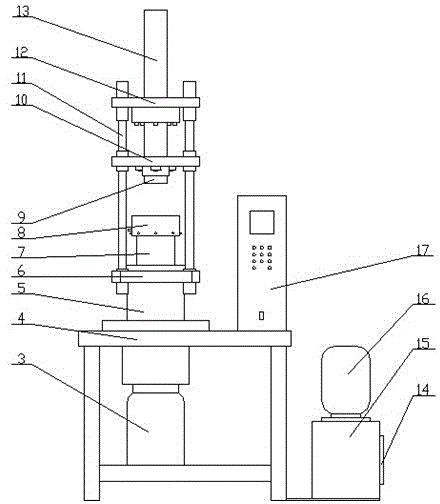

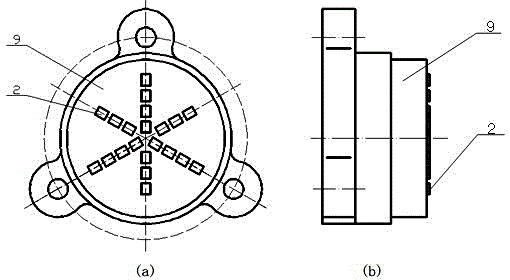

[0034] See Figure 1~2 , The device of the present invention consists of three parts: a rotary table, a hydraulic system and a roller pressure head (9). The rotary table is composed of a motor (3), a support (4), a base (5), a table top (7) and a fixture (8). Fixture (8) is fixed on the table top (7), the table top (7) is connected with the motor (3) and driven by the motor (3) to rotate, the table top (7) is installed on the base (5) , the base (5) is fixed on the support (4). Turn on the motor (3), the motor (3) drives the table top (7) to rotate, and the table top (7) drives the clamp (8) on it to rotate, and then drives the metal material sample (1) clamped on the clamp (8) ) rotation. The electric motor (3) used in this embodiment has a rotational speed adjustment range of 0~60r / s and a torque of 1.5kN·m.

[0035] The hydraulic system is composed of a hydraulic press, a power system and an electrical control system (17). Hydraulic machine is made up of lower plate (6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com