A kind of decomposition method of asbestos tailings

A technology of asbestos tailings and asbestos, applied in the direction of process efficiency improvement, silicate, alkali metal silicate, etc., can solve problems such as low decomposition rate, "three wastes" generation, and incomplete process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

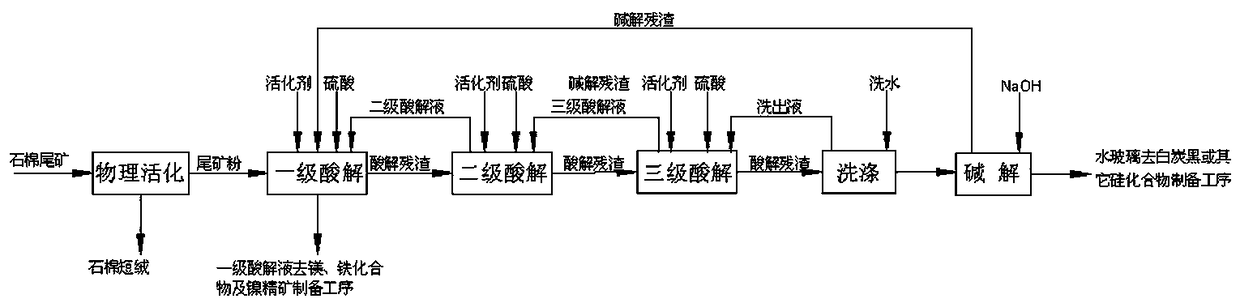

[0059] Example 1: Decomposition of asbestos tailings (without collecting short fibers)

[0060] A: Crush asbestos tailings to 120 mesh, asbestos tailings composition: SiO 2 : 41.81%, MgO: 35.74%, Fe 2 o 3 : 6.22%, NiO: 0.37%, CoO: 0.031%, Al 2 o 3 : 0.81%, loss on ignition: 13%.

[0061] B: Weigh 80kg of asbestos tailings powder (containing a small amount of short fluff) and the secondary acid hydrolysis solution at a solid-to-liquid ratio of 1:3 (secondary acid hydrolysis solution 240L) and mix them in the primary acid hydrolysis reactor, stir well and then add The activator is 800g, then the temperature is raised and sulfuric acid is added, the reaction temperature is controlled to be 80°C, the reaction time is 60min, and the final pH value is controlled to be 1. After the reaction was completed, 107kg of the first-grade acidolysis residue (48.5% water content, 55.1kg on dry basis) and 238L of the first-grade acidolysis solution were obtained by filtration.

[0062] Af...

Embodiment 2

[0070] Example 2: Decomposition of asbestos tailings (shrinking)

[0071] A: 100kg of asbestos tailings were crushed to 80 mesh, and 2.4kg of asbestos linters and 97.6kg of tailings powder were collected. The composition of tailings powder is: SiO 2 : 41.52%, MgO: 35.49%, Fe 2 o 3 : 6.34%, NiO: 0.38%, CoO: 0.041%, Al 2 o 3 : 0.88%, loss on ignition: 13.1%.

[0072] B: Weigh 80kg of asbestos tailings powder (excluding linters) and the secondary acid hydrolysis solution at a solid-to-liquid ratio of 1:3 (secondary acid hydrolysis solution 240L) and mix them in the primary acid hydrolysis reactor, stir well and then add 800g of activator, then heat up and add sulfuric acid, control the reaction temperature to 85°C, the reaction time is 40min, the pH value of the control end point is 0.8, after the reaction is completed, 108kg of first-grade acidolysis residue (water content 49.8%, dry weight 54.2kg) is obtained by filtration And primary acid solution 236L.

[0073] After a...

Embodiment 3

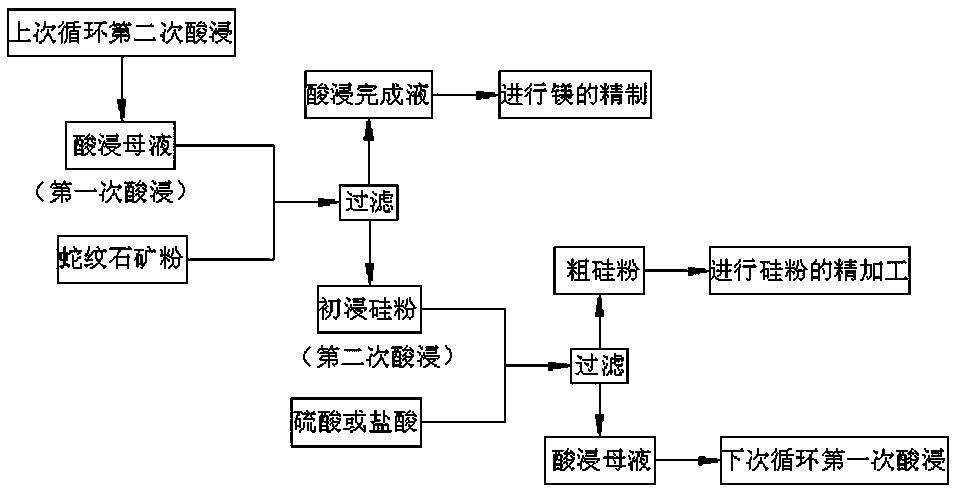

[0081] Embodiment 3: serpentine decomposes, as figure 2 shown

[0082] A: Crush 100kg of serpentine to 100 mesh, the composition is: SiO 2 : 39.21%, MgO: 34.46%, Fe 2 o 3 : 8.62%, NiO: 0.26%, CoO: 0.041%, Al 2 o 3 : 3.66%, loss on ignition: 11.88%.

[0083] B: Weigh 80kg of serpentine and the secondary acid hydrolysis solution according to the solid-to-liquid ratio of 1:4 (secondary acid hydrolysis solution 320L) and mix them in the primary acid hydrolysis reactor. After stirring evenly, add 800g of activator, then heat up and Sulfuric acid was added, the temperature was controlled at 90°C, the reaction time was 90 minutes, and the pH value at the end point was controlled to be 1. After the reaction was completed, 103 kg of the first-level acidolysis residue (52.66% water content, 48.8 kg on dry basis) and 304 L of the first-level acidolysis solution were obtained by filtration.

[0084] After analyzing and calculating the chemical composition of the primary acid hydrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com