High molecular material ultraviolet radiation aging device

A technology of polymer materials and aging equipment, which is applied in analysis materials, instruments, measuring devices, etc., can solve the problems of low light source utilization efficiency and complex equipment structure, and achieve high light source utilization efficiency, simple structure, and easy disassembly and installation of lamps. tube effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

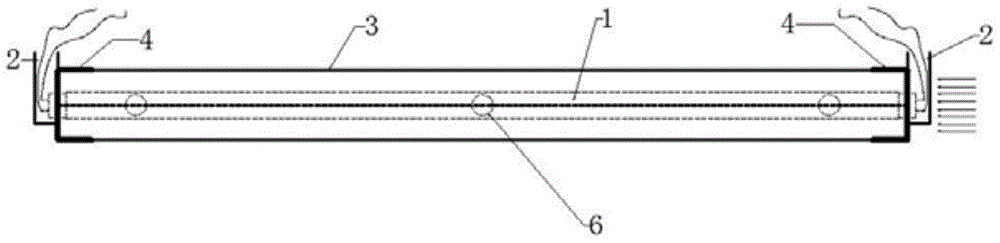

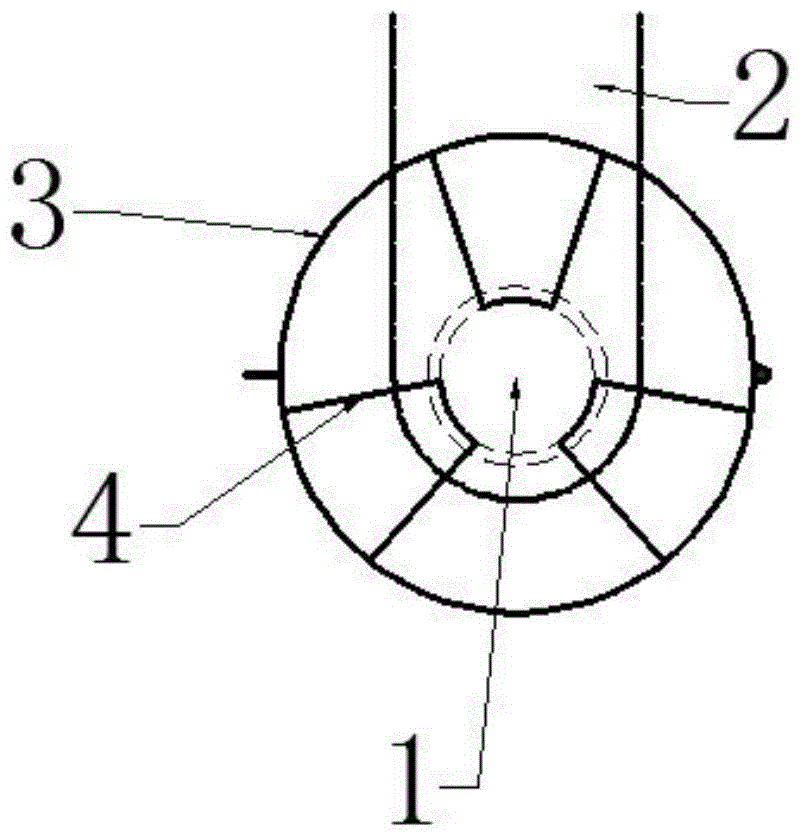

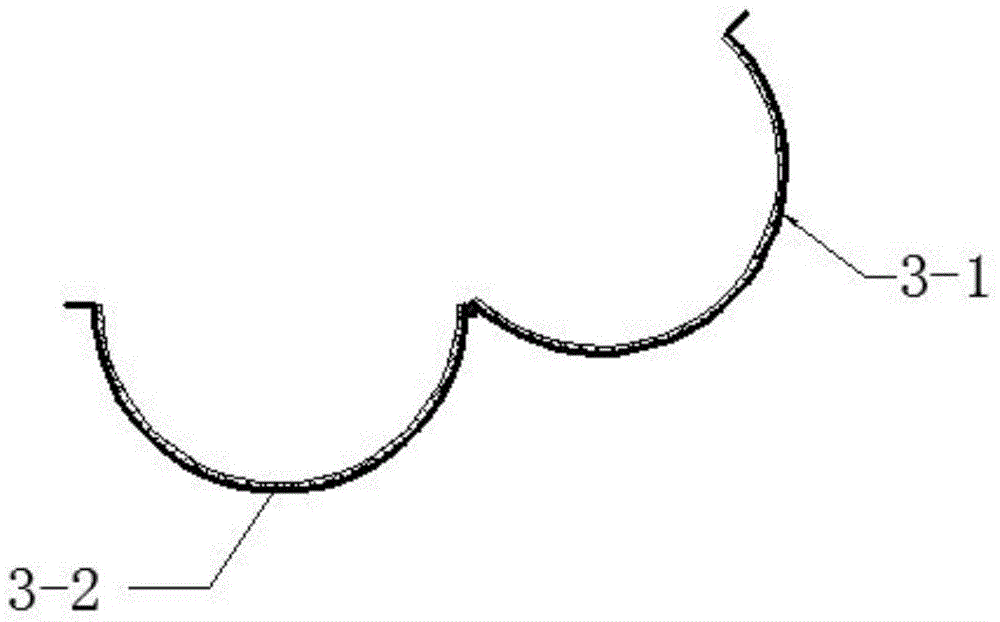

[0013] Specific embodiment 1: The ultraviolet aging equipment for polymer materials in this embodiment is composed of a fluorescent ultraviolet lamp tube 1, a lamp holder 2, a coating barrel 3, and two lamp tube support members 4, wherein the coating barrel 3 is composed of a left half cylinder 3-1 Hinged with the right semi-cylinder 3-2 to form a hollow cylinder, two tube-shaped lamp tube supports 4 are fastened to the two open ends of the coating barrel 3 respectively, and on the inner peripheral surface of the lamp tube support 4 There are three supporting frames 5 uniformly arranged on the top, and the supporting beams 5-1 on the supporting frames 5 and the fluorescent ultraviolet lamp tubes 1 are arc-shaped, and the arc-shaped supporting beams 5-1 on the three supporting frames 5 are all aligned with the fluorescent ultraviolet lamp tube 1. The outer tube surface of the ultraviolet lamp tube 1 is bonded, the lamp cap 2 is fixed on the lamp tube support member 4 , and a plu...

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment differs from Embodiment 1 in that the length of the coating barrel 3 is 1.20-1.25 m.

specific Embodiment approach 3

[0016] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the wall thickness of the coating barrel 3 is 1-3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com