Preparation method of sulfur ion fluorescent chemical sensor based on silicon nanowire or silicon nanowire array

A silicon nanowire array and chemical sensor technology, applied in the field of fluorescent chemical sensors, can solve the problems of cumbersome synthesis steps and achieve high sensitivity and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

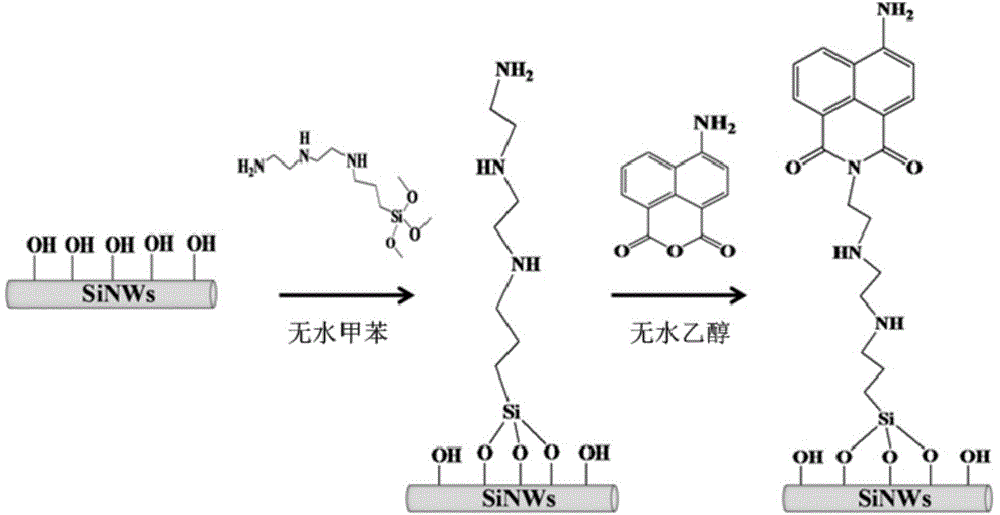

[0032] 1) Soak silicon nanowires with a diameter of 10-15 nm prepared by chemical vapor deposition in concentrated sulfuric acid (98% mass fraction) and H at a volume ratio of 1:1 2 o 2 (mass fraction is 5%) in the mixed solution, after the temperature is 95 ℃, carry out treatment for 30 minutes, after washing with deionized water to neutrality, normal temperature is soaked in the H that the volume ratio is 3:1:1 2 O:H 2 o 2 (mass fraction is 30%): NH 4 OH in a mixed solution for 2.5 hours, washed with water until neutral, and dried in vacuum to obtain hydroxylated silicon nanowires;

[0033] 2) At room temperature, dry 30 mg of the hydroxylated silicon nanowires obtained in step 1), 10 mL of anhydrous toluene and 0.1 mL of 3-[2-(2-aminoethylamino)ethylamino]propane Base-trimethoxysilane was added to the reactor, heated to 50°C under the protection of nitrogen, and reacted at constant temperature for 48 hours, then cooled to room temperature, and cleaned with ethanol to re...

Embodiment 2

[0039] 1) Soak the silicon nanowire array (the diameter of the silicon nanowire in the silicon nanowire array is 200-400nm and the length is 15-20μm) prepared by the chemical etching method with a silicon wafer size of 1cm×1cm in a volume ratio of 1:1 concentrated sulfuric acid (mass fraction is 98%) and H 2 o 2 (mass fraction is 5%) in the mixed solution, after the temperature is 95 ℃, carry out treatment for 30 minutes, after washing with deionized water to neutrality, normal temperature is soaked in the H that the volume ratio is 3:1:1 2 O:H 2 o 2 (mass fraction is 30%): NH 4 OH in a mixed solution for 2.5 hours, washed with water until neutral, and dried in vacuum to obtain a hydroxylated silicon nanowire array;

[0040] 2) At room temperature, dry the hydroxylated silicon nanowire array obtained in step 1), 10 mL of anhydrous toluene and 0.1 mL of 3-[2-(2-aminoethylamino)ethylamino]propane Base-trimethoxysilane was added to the reactor, heated to 50°C under the prote...

Embodiment 3

[0046] 1) Soak silicon nanowires with a diameter of 10-15 nm prepared by chemical vapor deposition in concentrated sulfuric acid (50% mass fraction) and H at a volume ratio of 8:1 2 o 2 (mass fraction is 30%) in the mixed solution, after treating at 70 ℃ for 90 minutes, after washing with deionized water to neutrality, soaking in H at room temperature with a volume ratio of 9:1:1 2 O:H 2 o 2 (Mass fraction is 5%): NH 4 OH in a mixed solution for 1 hour, washed with water until neutral, and dried in vacuum to obtain hydroxylated silicon nanowires;

[0047] 2) At room temperature, 50 mg of the hydroxylated silicon nanowires obtained in step 1), 30 mL of anhydrous toluene and 0.4 mL of 3-[2-(2-aminoethylamino)ethylamino]propyl- Trimethoxysilane was added to the reactor, heated to 90°C under the protection of nitrogen, reacted at constant temperature for 12 hours, then cooled to room temperature, and cleaned with acetone ultrasonically to remove unreacted 3-[2-(2-aminoethylami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com