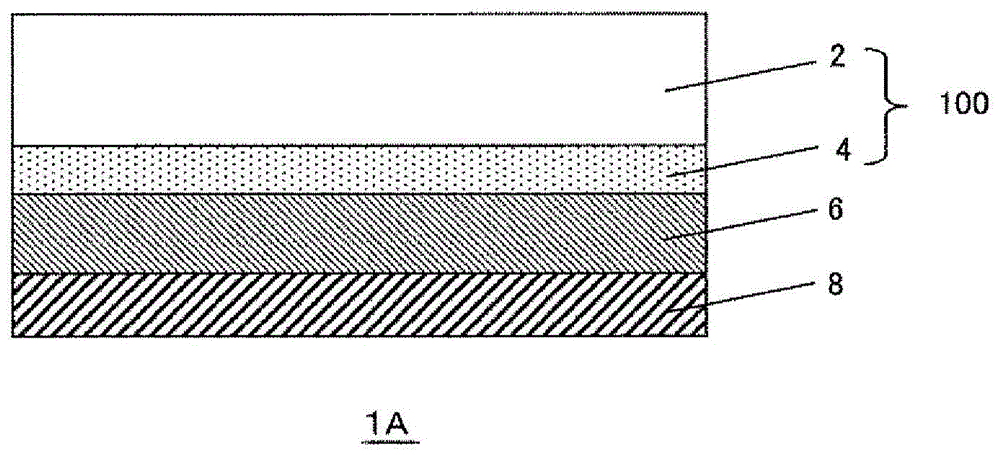

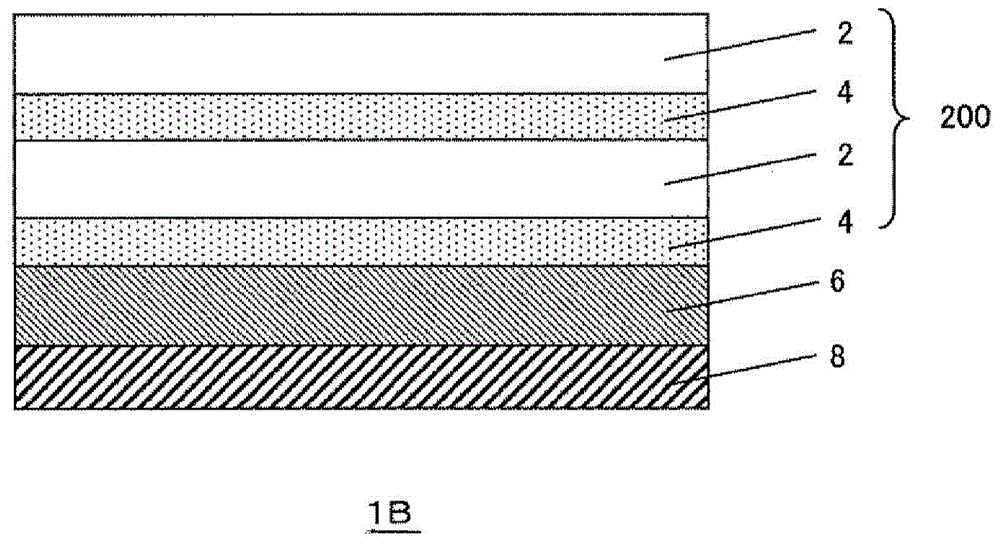

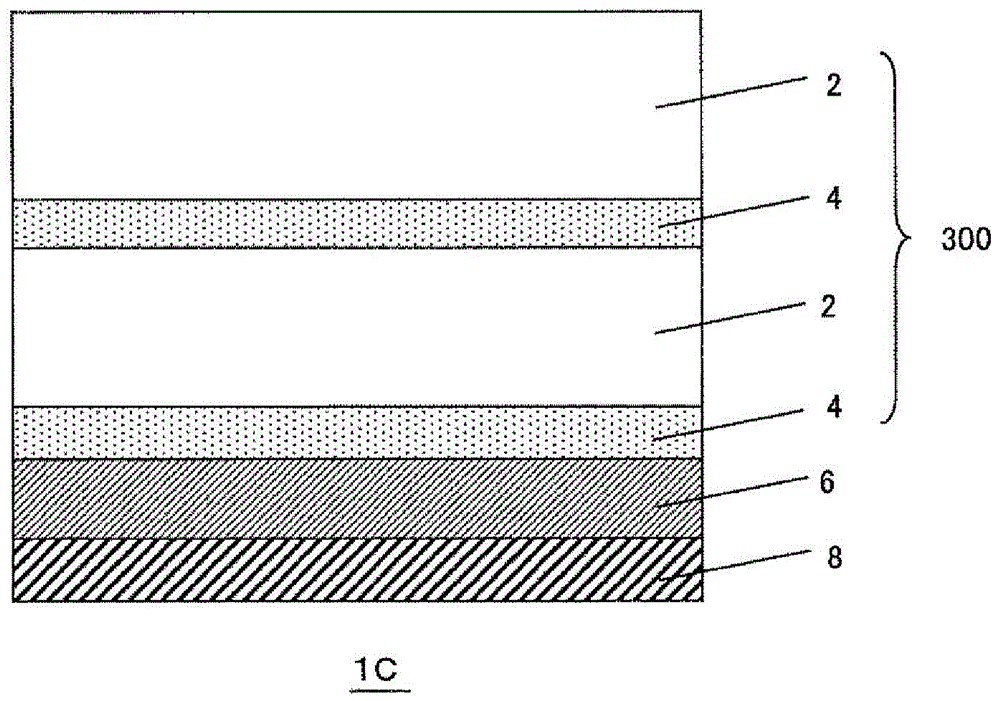

Silicon-containing film and method for forming silicon-containing film

A technology containing silicon film and silicon element, applied in the direction of gaseous chemical plating, nanotechnology, coating, etc., can solve the problems of reduced barrier property, peeling and cracking of sealing film, increased film stress, etc., and achieve the effect of stable barrier property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] An Ag layer with a thickness of 200 nm was formed on a part of the surface of the glass substrate. This substrate was placed on a substrate fixing table in the film formation chamber so that the surface having the Ag layer faced the loop antenna side. Then the internal pressure of the film forming chamber is decompressed to 9.9×10 through the exhaust system -5 Below Pa. After the decompression in the film-forming chamber is completed, HMDSO gas is introduced into the film-forming chamber. The introduction rate of the HMDSO gas is 3 sccm to 45 sccm.

[0092] Next, a high-frequency current is passed from the high-frequency power supply to the loop antenna. The plasma power at this time was 1 kW to 10 kW. A surface reaction proceeds on the surface of the substrate to form a base film covered with a plastic film. After 1 minute, the flow control valve was closed to stop the introduction of HMDSO gas.

[0093] After the formation of the base film, a stress relaxation l...

Embodiment 2~5 and comparative example 1~8

[0097] In Example 1, each laminated body was obtained in the same manner as in Example 1, except that the thicknesses of the stress relaxation layer and the barrier layer and the number of layers were changed as shown in Table 2. In Comparative Examples 2 and 5, no barrier layer was provided.

[0098] Peeling evaluation immediately after film production

[0099] The peeling state immediately after film formation of the laminated bodies obtained in Examples 1-5 and Comparative Examples 1-8 was visually observed. The results were evaluated according to the following criteria. The results are shown in Table 2.

[0100] ○: No peeling or peeling of the silicon-containing film was observed

[0101] ×: Peeling and peeling of the silicon-containing film were observed

[0102] In the results of the above test, peeling and peeling of the silicon-containing film were observed in the laminates of Comparative Examples 1 and 4. Peeling and peeling of the silicon-containing film were no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com