Sugar-free zinc lysine granule composition and preparation method

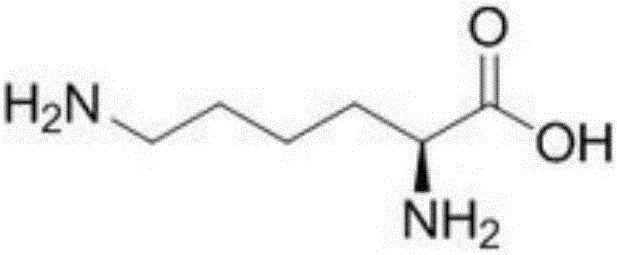

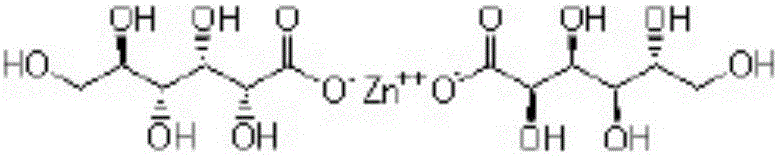

A technology of zinc lysine and its composition, which is applied in the field of medicine, and can solve problems such as uneven packaging and inclusion, low particle hardness, and poor compliance of children and patients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0133] Embodiment 1: preparation zinc lysine gluconate granule composition

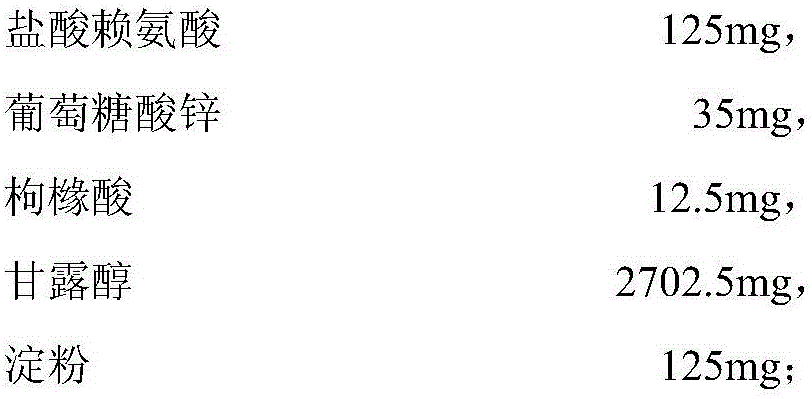

[0134] formula:

[0135]

[0136] Preparation method:

[0137] (1) dissolving citric acid in an appropriate amount of water (the amount of water is 90 times the weight of citric acid), then adding zinc gluconate and lysine hydrochloride successively and dissolving it to obtain a clear solution;

[0138] (2) Adjust an appropriate amount of starch (accounting for 50% of the prescription amount) into a paste with 2 times the weight of water, then mix it evenly with the solution obtained in step (1), stir and heat up to 70° C. to obtain solution I, spare;

[0139] (3) Make the remaining amount of starch into a paste with 8 times the weight of water, stir and heat up to 70°C at the same time to obtain solution II, which is set aside;

[0140] (4) Put the prescribed amount of mannitol into the fluidized bed granulator, mix for 5 minutes, turn on the heating to 70°C, spray into solution I, and then s...

Embodiment 2

[0143] Embodiment 2: preparation zinc lysine gluconate granule composition

[0144] formula:

[0145]

[0146] Preparation method:

[0147] (1) dissolving citric acid in an appropriate amount of water (the amount of water is 80 times the weight of citric acid), then adding zinc gluconate and lysine hydrochloride successively and dissolving them to obtain a clear solution;

[0148] (2) Adjust an appropriate amount of starch (accounting for 60% of the prescription amount) into a paste with 2 times the weight of water, then mix evenly with the solution obtained in step (1), stir and heat up to 65° C. to obtain solution I, spare;

[0149] (3) Make the remaining amount of starch into a paste with 6 times the weight of water, stir and heat up to 75°C at the same time to obtain solution II, which is set aside;

[0150] (4) Put the prescribed amount of mannitol into the fluidized bed granulator, mix for 5 minutes, turn on the heating to 65°C, spray into solution I, and then sp...

Embodiment 3

[0153] Embodiment 3: preparation zinc lysine gluconate granule composition

[0154] formula:

[0155]

[0156] Preparation method:

[0157] (1) dissolving citric acid in an appropriate amount of water (the amount of water is 110 times the weight of citric acid), then adding zinc gluconate and lysine hydrochloride successively and dissolving it to obtain a clear solution;

[0158] (2) Adjust an appropriate amount of starch (accounting for 40% of the prescription amount) into a paste with 2 times the weight of water, then mix it evenly with the solution obtained in step (1), stir and heat up to 75° C. to obtain solution I, spare;

[0159](3) Make the remaining amount of starch into a paste with 10 times the weight of water, stir and heat up to 75°C at the same time to obtain solution II, which is set aside;

[0160] (4) Put the prescribed amount of mannitol into the fluidized bed granulator, mix for 5 minutes, turn on the heating to 75°C, spray into solution I, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com