Irregular micro-gel preparation method based on liquid bridge phenomenon

An irregular, microgel technology, applied in chemical instruments and methods, colloidal chemistry, colloidal chemistry, etc., to achieve the effect of easy internal gradient and high throughput, not limited by materials, and adjustable in shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

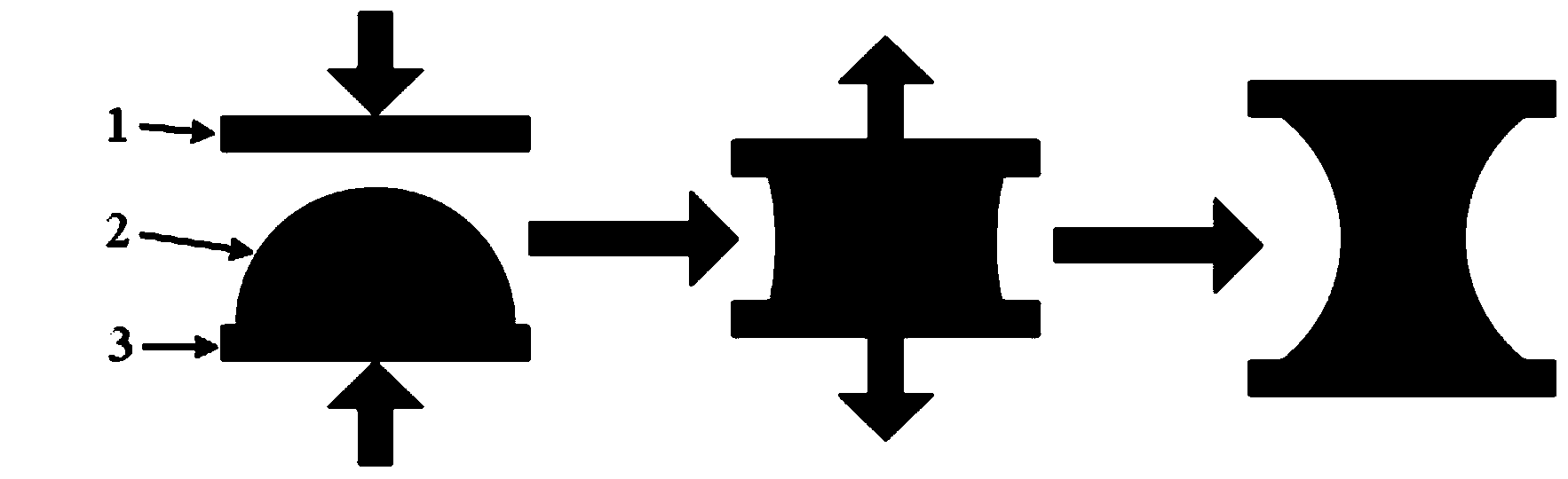

[0036] The irregular microgel preparation method based on the liquid bridge phenomenon provided by the invention, such as figure 1 As shown, there are first and second surface materials 1 and 2 in contact with the hydrogel precursor droplet 3, and the hydrogel precursor droplet 3 that can form a liquid bridge. The height of the stretched or compressed liquid bridge and the first and second surface materials can be adjusted by controlling the hydrophilicity and hydrophobicity of the first and second surface materials in contact with the hydrogel precursor droplet, and the volume size of the hydrogel precursor droplet. The shapes of different shapes of irregular microgels can be regulated. The specific steps are:

[0037] Step 1: Adopt a lifting mechanical platform that can control the tension or compression height of the liquid bridge, fix the first surface material 1 on the liftable end of the lifting mechanical platform, and fix the second surface material 2 on the fixed end...

Embodiment 1

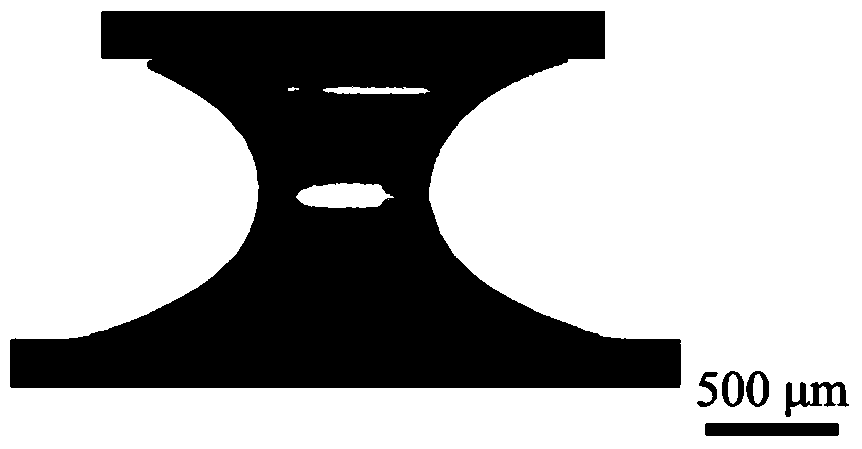

[0049] Example 1 Schematic diagram of polyethylene glycol microgels prepared on glass surfaces on both upper and lower surfaces and numerical simulation results

[0050] Step 1: Fix two glass slides on the fixed end and the liftable end of the lifting mechanical platform, respectively, to ensure that the slides and the lifting mechanical platform are firmly fixed, and ensure that the two slides are completely horizontal.

[0051] Step 2: Weigh a certain amount of PEG1000 monomer, dissolve it in ultrapure water, and prepare a PEG solution with a mass concentration of 10%. Then add 2-hydroxy-2-methyl propiophenone (the mass is 0.5% of the PEG solution) into the prepared PEG solution, shake it sufficiently to make it mix evenly, and obtain the first mixed solution (hydrogel precursor solution). Use a micropipette to draw 2 μl of the first mixed solution, and slowly add it dropwise onto the glass slide below the lifting platform.

[0052] Step 3: Adjust the lifting mechanical pla...

Embodiment 2

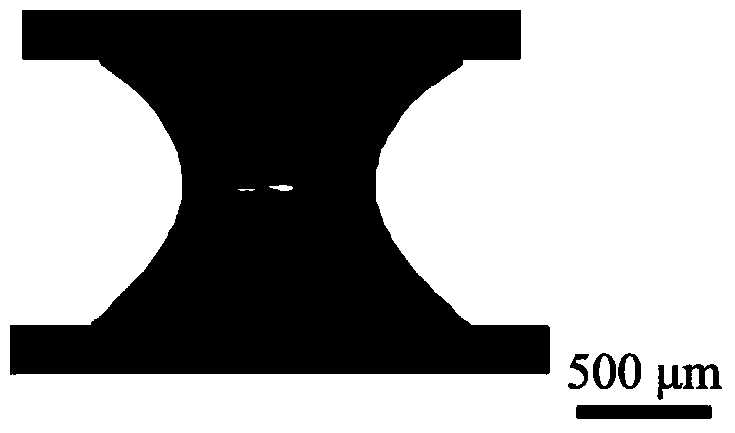

[0054] Example 2 Schematic diagram and numerical simulation results of polyacrylamide microgels prepared on the surface of PMMA plates on the upper and lower surfaces

[0055] Step 1: Fix two PMMA boards on the fixed end and the liftable end of the lifting machinery platform respectively, to ensure that the PMMA board and the lifting machinery platform are firmly fixed, and to ensure that the two PMMA boards are completely level.

[0056] Step 2: Weigh acrylamide, methylene bisacrylamide and ammonium persulfate into a beaker, the mass ratio of methylene bisacrylamide to acrylamide is 0.00375:1, and the mass ratio of ammonium persulfate to acrylamide is 0.0175:1 , then add ultrapure water to make the concentration of acrylamide 0.2g / ml, stir to dissolve the solid, and finally add N,N,N',N'-tetramethyldiethylamine, the mass ratio of which to acrylamide is 0.0068:1, the second mixture was obtained after mixing. Use a micropipette to draw 1 μl of the second mixed solution (hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com