Preparation method and application of a mesoporous silicon composite lead ion imprinted polymer

A technology of ion imprinting and composite lead, which is applied in the preparation of mesoporous materials composite lead ion imprinting polymers, material preparation, and the application field of dynamic adsorption of lead ions, to solve the problem of uneven distribution of imprinted sites, solve pore blockage, and quickly The effect of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

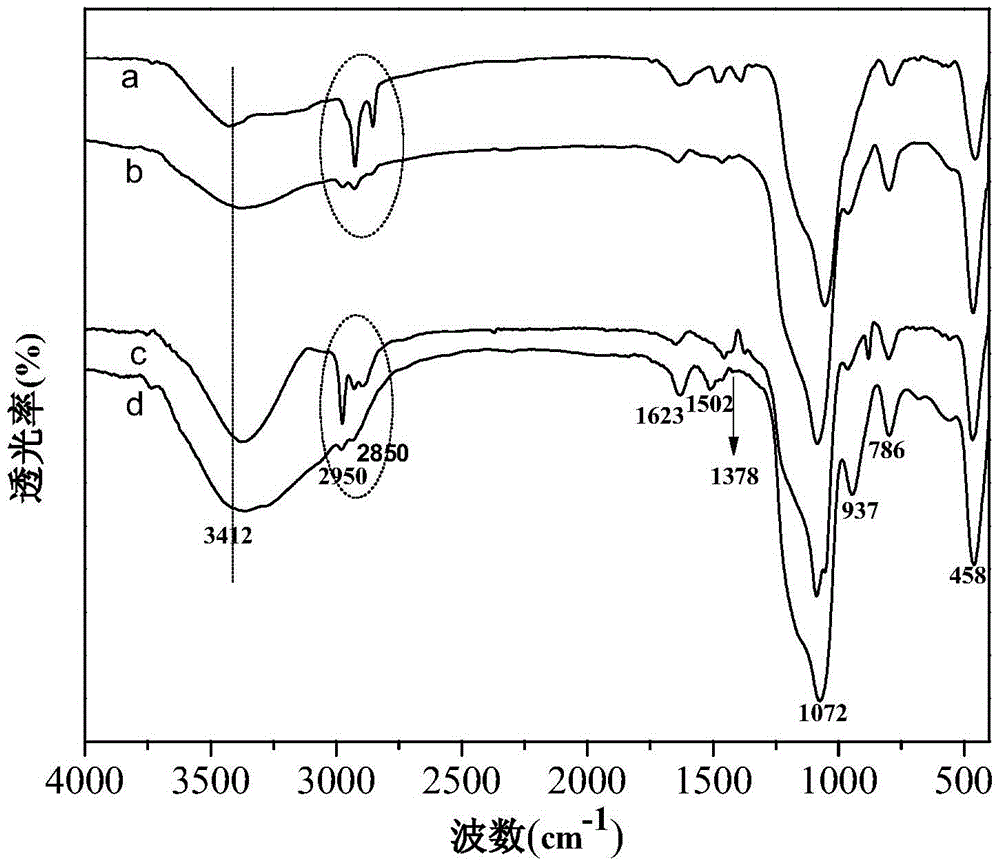

Image

Examples

Embodiment 1

[0025] (1) (Pb(NO 3 ) 2 ) and APTES, dissolved in 25mL deionized water, in which the concentration of Pb(II) in the control solution was 4mmol / L, and the concentration of APTES was 16mmol / L, stirred for 2h; 0.2gCTAB was dissolved in 25mL deionized water, and ultrasonically After 1h, add to the above solution, mix and stir for 1h;

[0026] (2) Use 2mol / L sodium hydroxide aqueous solution to adjust the pH of the mixed solution obtained in step (1) to 8.0. After stirring for 1 hour, add TEOS dropwise under the condition of 300rpm mechanical stirring, control the concentration of TEOS to 4 mmol / L, add dropwise After completion, mix and stir for 2h;

[0027] (3) Put the solid-liquid mixture obtained in step (2) into a 100mL high-temperature reactor, and place the reactor in an oven at 100°C for 48 hours;

[0028] (4) The solid product is collected by filtration, washed with a large amount of water, and then the template agent CTAB and template lead ions are eluted with a mixed s...

Embodiment 2

[0036] (1) Pb(NO 3 ) 2 and AAPTS, dissolved in 25mL deionized water, in which the concentration of Pb(II) in the control solution was 40mmol / L, the concentration of AAPTS was 160mmol / L, and stirred for 2h to obtain; 2.0g CTAB was dissolved in 25mL deionized water, 40°C After ultrasonication for 1h, add to the above solution, mix and stir for 1h;

[0037] (2) Adjust the pH of the mixed solution obtained in step (1) to 12.0 with 2mol / L aqueous sodium hydroxide solution, and after stirring for 1 hour, add TEOS dropwise under 500rpm mechanical stirring conditions, control the concentration of TEOS to 400mmol / L, and complete the dropwise addition After that, mix and stir for 2h;

[0038] (3) Put the solid-liquid mixture obtained in step (2) into a 100mL high-temperature reactor, and place the reactor in an oven at 150°C for 96 hours;

[0039] (4) The solid product was collected by filtration and washed with a large amount of water. Then, the template agent CTAB and template lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com