Preparation method of seed crystal-free fine monocrystal diamond micro-powder

A diamond and diamond single crystal technology, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of ignoring the influence of growth and lattice distortion of single crystal particles, and achieve concentrated size distribution and high Impact resistance, the effect of eliminating the particle size screening process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

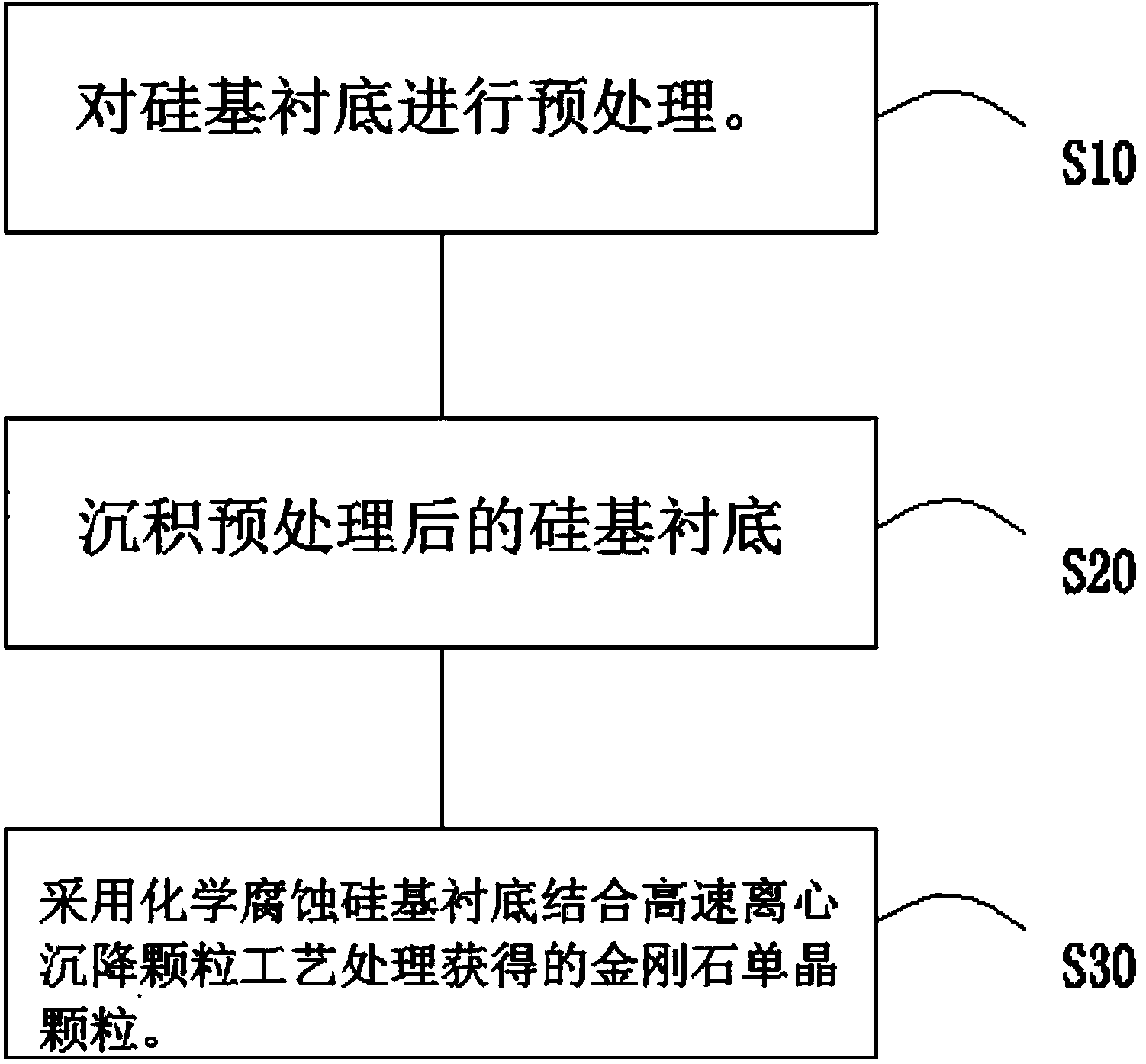

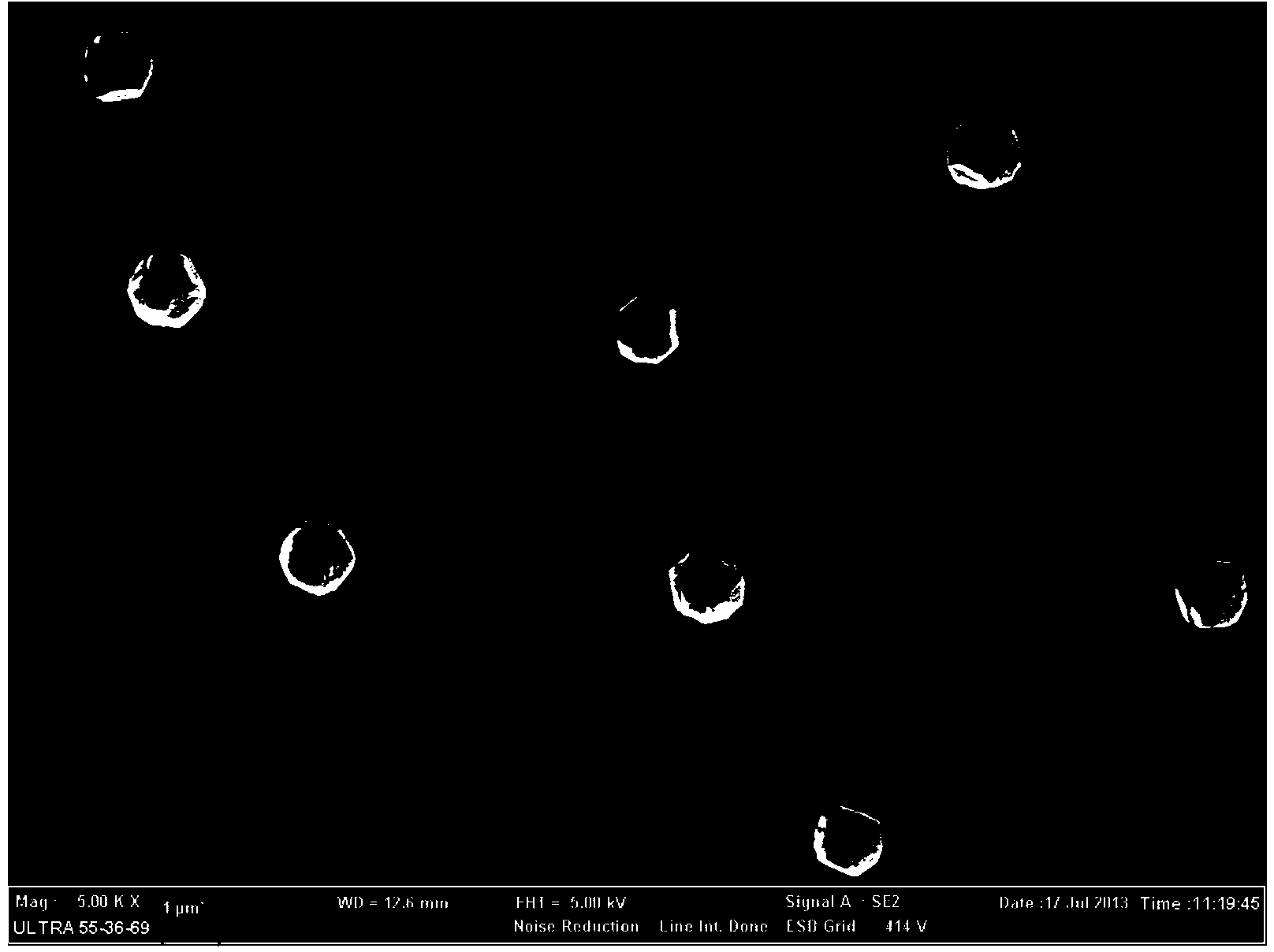

[0030] The preparation of M0 / 0.5 particle size CVD high-grade fine diamond single crystal micropowder is carried out on the mirror polished single crystal silicon substrate.

[0031] First, the surface of the silicon-based substrate was uniformly mechanically ground for 0.5 min with 0.5 μm diamond micropowder, and then the mechanically ground silicon-based substrate was ultrasonically cleaned in deionized water and acetone solution for 3 min.

[0032] Next, put the pretreated silicon-based substrate into the reaction chamber of the hot-wire CVD device for deposition. The hot-wire adopts a twisted-pair tantalum wire with a diameter of Φ0.4mm, and arranges the hot-wire in parallel on the silicon-based substrate. Above, and use high temperature resistant springs to keep the hot wire in a straight and horizontal state during the deposition process. After the reaction chamber is evacuated, the reaction gas (hydrogen and acetone) is introduced, and after adjusting the pressure of th...

Embodiment 2

[0036] The preparation of CVD high-grade fine diamond single crystal powder with M0 / 1 particle size is carried out on the mirror polished single crystal silicon wafer as the substrate.

[0037] First, the silicon-based substrate surface was uniformly mechanically ground for 1 min with 2.0 μm diamond micropowder, and then the mechanically ground silicon-based substrate was ultrasonically cleaned in deionized water and acetone solution for 5 min, respectively.

[0038] Next, put the pretreated silicon-based substrate into the reaction chamber of the hot-wire CVD device for deposition. The hot-wire adopts a twisted-pair tantalum wire with a diameter of Φ0.4mm, and arranges the hot-wire in parallel on the silicon-based substrate. Above, and use high temperature resistant springs to keep the hot wire in a straight and horizontal state during the deposition process. After the reaction chamber is evacuated, the reaction gas (hydrogen and acetone) is introduced, and after adjusting th...

Embodiment 3

[0042] The preparation of M0.5 / 1 particle size CVD high-grade fine diamond single crystal micropowder is carried out on the mirror polished single crystal silicon substrate.

[0043] First, the silicon-based substrate surface was uniformly mechanically ground for 0.7 min with 2.0 μm diamond micropowder, and then the mechanically ground silicon-based substrate was ultrasonically cleaned in deionized water and acetone solution for 4 min, respectively.

[0044] Next, put the pretreated silicon-based substrate into the reaction chamber of the hot-wire CVD device for deposition. The hot-wire adopts a twisted-pair tantalum wire with a diameter of Φ0.4mm, and arranges the hot-wire in parallel on the silicon-based substrate. Above, and use high temperature resistant springs to keep the hot wire in a straight and horizontal state during the deposition process. After the reaction chamber is evacuated, the reaction gas (hydrogen and acetone) is introduced, and after adjusting the pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com