Chemical mechanical cleaning method of SiC epitaxial wafer and special-purpose tools

A technology of chemical machinery and special tools, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to reduce roughness, improve wafer surface morphology, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

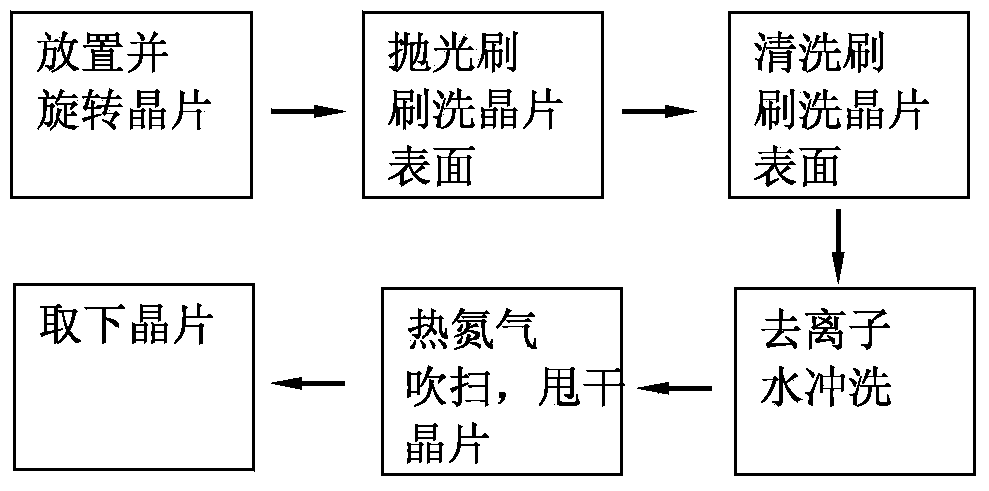

[0029] See Figure 2-4 Shown, a kind of chemical mechanical cleaning method of SiC epitaxial wafer, comprises the following steps:

[0030] First, the SiC epitaxial wafer that needs to be cleaned is placed on a corrosion-resistant pedestal, and the wafer will be rotated through the pedestal. Usually the susceptor can be driven by a motor, and the wafer is held by holding clamps on the susceptor. The rotation speed of the base can be adjusted according to needs, and there is no need to specifically limit the rotation speed. It can usually be maintained at about 1000 rotations per minute, and the rotation speed can be adjusted according to the degree of cleaning.

[0031] Secondly, a corrosion-resistant brush is used as the polishing brush. The polishing brush rotates and moves back and forth along the radial direction of the wafer to perform chemical polishing on the surface of the wafer. During the cleaning process, the polishing liquid will be sprayed on the surface of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com