Ground coal gangue powder concrete as well as preparation and application methods thereof

A technology of coal gangue powder and concrete, which is applied in the field of concrete, can solve the problems of polluting the environment, producing harmful and toxic gases, etc., and achieves the effects of improving fluidity and enhancing resistance to chloride ion permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0026] In the present invention, the components involved are all in mass percent.

[0027] The present invention is achieved in that a kind of pulverized coal gangue powder concrete comprises:

[0028] Study the chemical composition, particle size distribution and microscopic morphology of a finely ground coal gangue powder, and test its performance with reference to "Fly Ash Used in Cement and Concrete" GB / T 1596-2005;

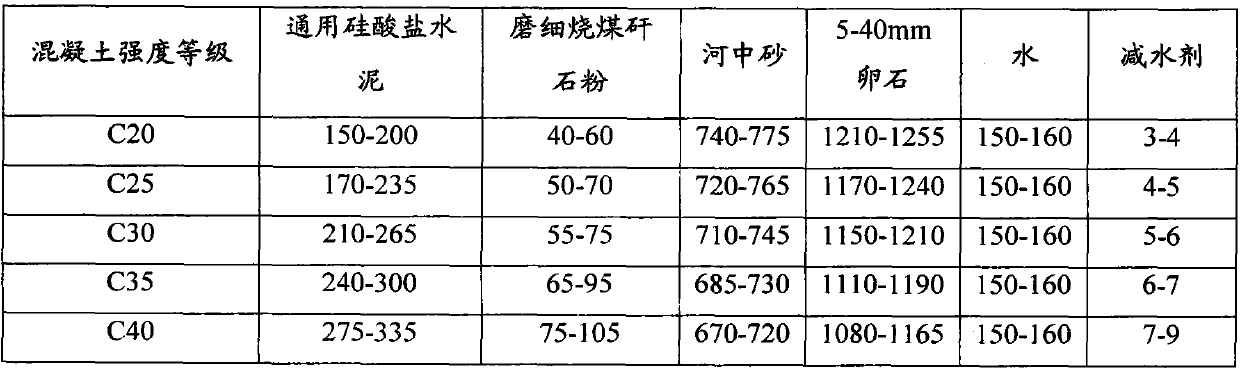

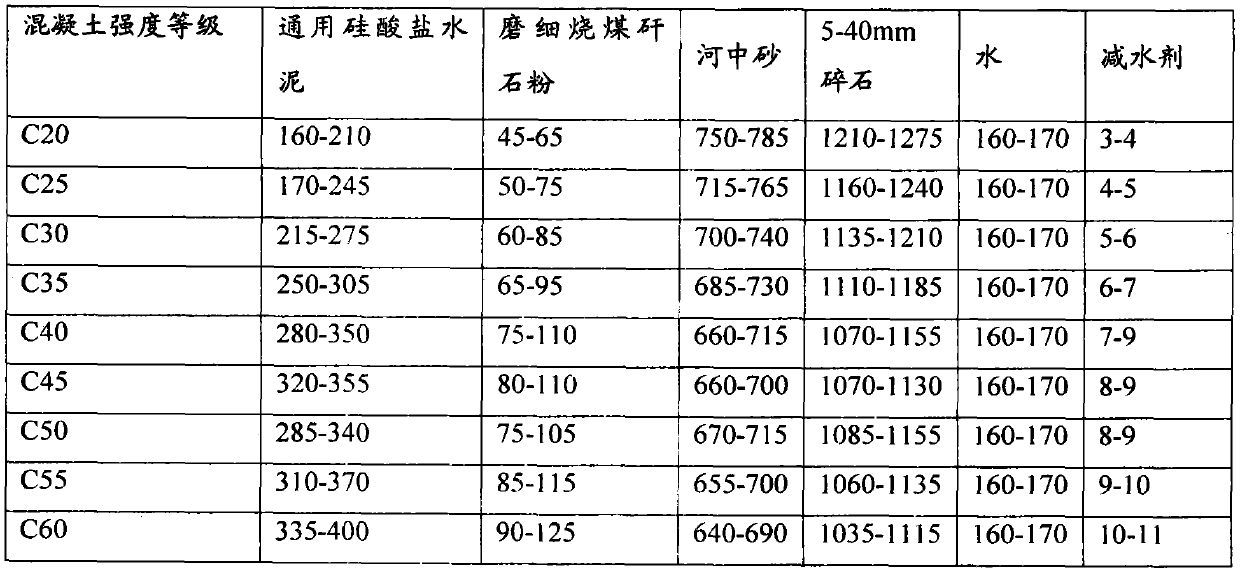

[0029] Taking C20-C60 concrete as the research object, 20%-30% ground burnt coal gangue powder is mixed into the concrete to study the workability, strength and durability of the ground burnt coal gangue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com