Preparation method of environment-friendly petroleum-base rubber softening functional material

A technology of rubber softening and functional materials, which is applied in the direction of building insulation materials, only multi-stage series refining process treatment, building components, etc., can solve the problems of cumbersome process, increase production cost and safety requirements, and achieve simple synthesis process and compatibility Good compatibility and good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Take 1 kg of the fraction of vacuum residue oil at 480-560 °C as raw material, heat it to 270 °C at a rate of 3 °C / min, add 40 g of dicumyl peroxide (DCP) as a free radical initiator, and simultaneously start from the reaction Oxygen is fed into the bottom of the device, and the flow rate of oxygen is 12L / h. After reacting for 8 hours, an environment-friendly petroleum-based rubber softening functional material was obtained.

Embodiment 2

[0021] Example 2: Take 1kg of the fraction of vacuum residue oil at 480-560°C as raw material, heat it to 210°C at a rate of 4°C / min, add 45g of free radical initiator benzoyl peroxide, and simultaneously feed Oxygen, the oxygen flow rate is 16L / h. After 10 hours of non-catalytic oxidation reaction, an environment-friendly petroleum-based rubber softening functional material was obtained.

Embodiment 3

[0022] Example 3: Take 1kg of the fraction of vacuum residue oil at 480-560°C as raw material, heat it to 260°C at a rate of 5°C / min, add 50g of free radical initiator cyclohexanone peroxide and tert-butyl hydroperoxide , while feeding oxygen from the bottom of the reactor, the oxygen flow rate is 18L / h. After 12 hours of non-catalytic oxidation reaction, an environment-friendly petroleum-based rubber softening functional material was obtained.

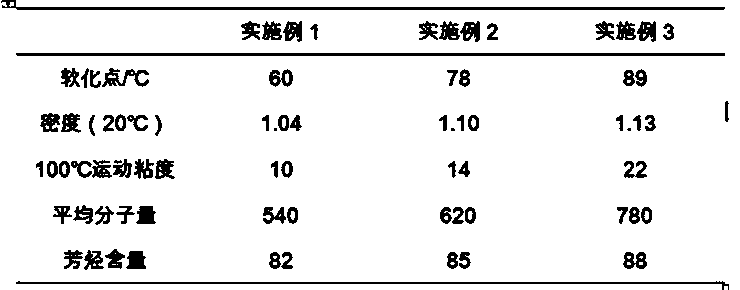

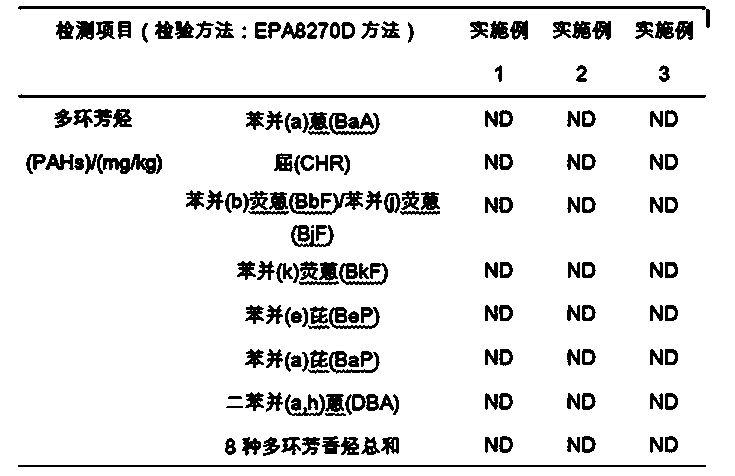

[0023] The basic properties of the environment-friendly petroleum base rubber softening functional material in embodiment 1-3 are shown in the following table:

[0024] Product properties in table 1-each embodiment

[0025]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap