Preparation method of low-internal-loss medium-resistant polyurethane elastomer material for vibration isolators

A polyurethane elastomer and vibration isolator technology, applied in the field of material preparation, can solve the problems of material aging, poor mobility, insufficient aging resistance, etc., and achieve the effects of small internal friction, excellent oil resistance, and simple and feasible preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

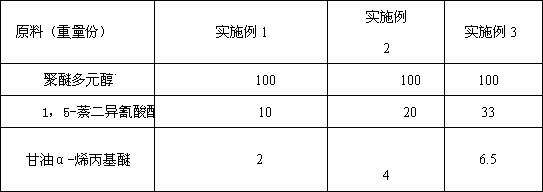

[0021] The following table examples 1-3 are the formula quantities for preparing polyurethane raw rubber.

[0022]

[0023] After the polytetrahydrofuran ether PTMG was vacuum dehydrated at 120°C for 2 hours, the polytetrahydrofuran ether was placed in a three-necked flask in an oil bath at 100°C under the protection of nitrogen according to the formula in the above table, and 1 was added at a speed of 200rad / min. 5-Naphthalene diisocyanate NDI, increase the stirring speed to 1000rad / min, mix NDI in PTMG evenly and react, add glycerol α-allyl ether as a chain extender after mixing for 30min, and continue to react for 20min. The product was poured out and treated in an oven at 120° C. for 6 hours to obtain polyurethane synthetic raw rubber.

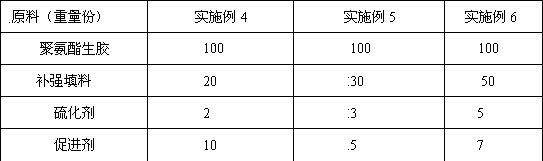

[0024] The following table examples 4-6 are the formula quantities for preparing the mixed rubber material.

[0025]

[0026] Accelerator D or Accelerator M are trade names. After kneading evenly on the open mill, put the sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com