Pea protein powder and application thereof to meat product and production method of pea protein powder

A technology for pea protein powder and meat products, applied in the application, the function of food ingredients, food preparation and other directions, can solve the problems of soybean production not meeting the demand, sensitive to the safety of genetically modified food, etc., to improve the level of physical health, nutritional value and High safety and the effect of widening application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

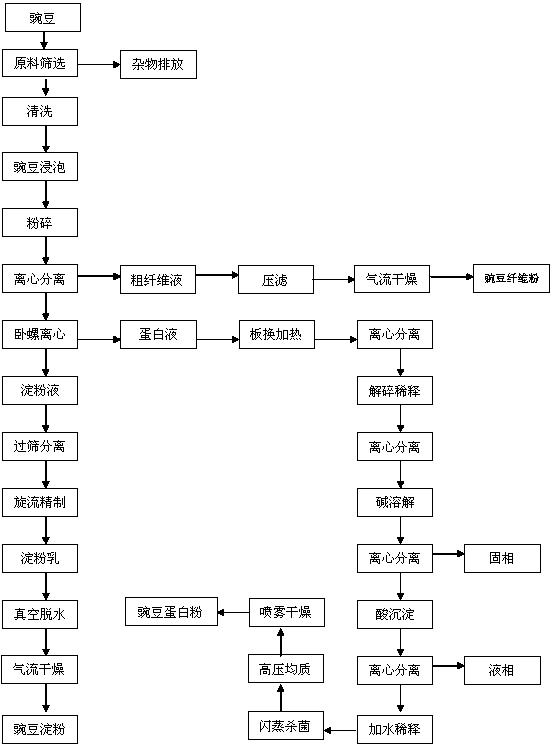

Method used

Image

Examples

Embodiment 1

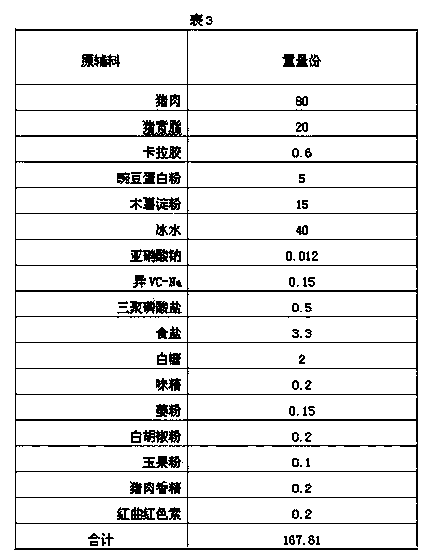

[0096] Example 1 is the composition, proportion and production method of the smoked and boiled sausage meat product of the present invention.

[0097] The meat product in this example is based on adding starch, completely replacing soybean protein isolate with pea protein powder, and additionally adding pea fiber powder. Its formula is shown in Table 1 below.

[0098]

[0099] Embodiment 1 smoked and cooked sausage processing flow chart as figure 2 shown.

[0100] Embodiment 1 concrete production steps are as follows:

[0101] (1) Raw material processing: thaw the pork naturally, and remove the visible fascia in the pork;

[0102] (2) Coarse grounding: use a 2mm hole plate to make pig back fat, and use a 5mm hole plate to make pork;

[0103] (3) Weighing: Weigh the auxiliary materials of corresponding quality according to the product formula in Table 1 above;

[0104] (4) Cutting and mixing: add salt additives (salt, nitrite, tripolyphosphate) and then add 1 / 2 of th...

Embodiment 2

[0113] Example 2 is the composition, proportion and production method of the rough ground smoked sausage product of the present invention. In Example 2, the soybean protein isolate is completely replaced by the pea protein powder of the present invention, and its formula is shown in Table 2 below.

[0114]

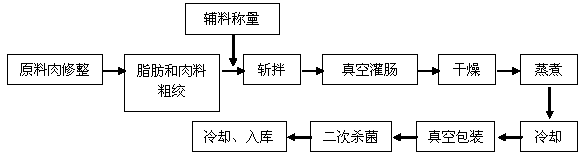

[0115] Example 2 The flow chart of the processing method for thickly twisted smoked and boiled sausages is as follows image 3 shown.

[0116] Embodiment 2 concrete production steps are as follows:

[0117] (1) Raw material processing: thaw the pork naturally, and remove the visible fascia in the pork;

[0118] (2) Coarse grounding: use a 2mm hole plate to make pig back fat, and use a 5mm hole plate to make pork;

[0119] (3) Weighing: According to the product formula in Table 2, weigh raw and auxiliary materials of corresponding quality;

[0120] (4) Stirring: add salt additives (salt, sodium nitrite, tripolyphosphate) and add about 1 / 2 of the total amount of ice w...

Embodiment 3

[0129] Example 3 is the composition, proportion and production method of the high-temperature ham sausage product of the present invention.

[0130]

[0131] Table 3 is a recipe for using pea protein powder instead of soy protein isolate.

[0132] Embodiment 3 high-temperature ham sausage processing method process flow chart is as Figure 4 shown.

[0133] Embodiment 3 concrete production steps are as follows:

[0134] (1) Raw material processing: thaw the pork naturally, and remove the visible fascia of the pork;

[0135] (2) Coarse grounding: first use a 2mm orifice plate to make pig back fat, and then use a 5mm orifice plate to make pork;

[0136] (3) Weighing: Weigh the auxiliary materials of corresponding quality according to Table 3;

[0137] (4) Chop and mix: Add salt additives (salt, sodium nitrite, tripolyphosphate) and add about 1 / 2 of the total amount of ice water, first chop and mix at low speed for 3 to 6 minutes, then chop and mix at high speed for 5 to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com