Sodium borohydride reduction adopted method for preparing Pd/alpha-Al2O3 catalyst

A technology of sodium borohydride and catalyst, which is applied in the field of preparation of Pd/α-Al2O3 catalyst by reduction of sodium borohydride, can solve the problems of complex preparation method, reduction of catalyst dosage, high space-time yield of oxalate, and achieve low The effect of heat release and good active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention discloses a method for preparing Pd / α-Al by reducing sodium borohydride 2 o 3 The preparation method of catalyst, its preparation steps are:

[0025] (1) the precursor of palladium and the precursor of auxiliary agent are dissolved in the solution of certain pH value to make impregnation solution;

[0026] (2) The calcined α-Al 2 o 3 Add the balls to the dipping solution prepared in step (1), and then stand at 40-60°C for 6-24 hours;

[0027] (3) α-Al after processing by step (2) 2 o 3 Put the ball into the oven and dry at 100-200°C for 12-24 hours;

[0028] (4) α-Al processed by step (3) 2 o 3 Balls, washed thoroughly with deionized water;

[0029] (5) α-Al after washing 2 o 3 The balls are fully dried in the oven;

[0030] (6) sodium borohydride and dissolved in a certain volume of alkaline solution to obtain a reducing solution;

[0031] (7) α-Al after step (5) is processed 2 o 3 Add the spheres to the reducing solution prepared in step (...

example 1

[0042] (1) Preparation of catalyst

[0043] Dissolve 0.075g of palladium chloride and 0.040g of ferric nitrate as an auxiliary agent in 15ml of hydrochloric acid buffer at pH=1.1 to prepare an impregnating solution. Add 15g of calcined alumina balls to 15ml of the impregnating solution. Place it for 12 hours, then put it in a drying oven and dry it at 150°C for 20 hours; fully soak and wash it with 5 times the volume of deionized water, and wash it 10 times with an interval of 2-3 hours each time. Continue drying in the oven for 12 hours, add the obtained palladium-loaded alumina balls into the prepared reducing solution of sodium borohydride and sodium hydroxide at a concentration of 0.6 g / L, soak for 8 hours, wash and dry to obtain the finished catalyst product B2.

[0044] (2) Performance evaluation and life investigation

[0045] A fixed bed reactor is adopted, the diameter of the reaction tube is 15 mm, and the temperature is controlled in two stages. Add 15ml of cataly...

example 2

[0047] In Example 1, the concentrations in the sodium borohydride reducing solution added in the preparation of the catalyst are respectively: 0, 0.4g / L, 0.8g / L, 1.0g / L, 1.2g / L, that is, samples B0 and B1 of the cost example , B3, B4, B5.

[0048] Performance evaluation condition is the same as example 1, and the yield of dimethyl oxalate is as follows respectively:

[0049]

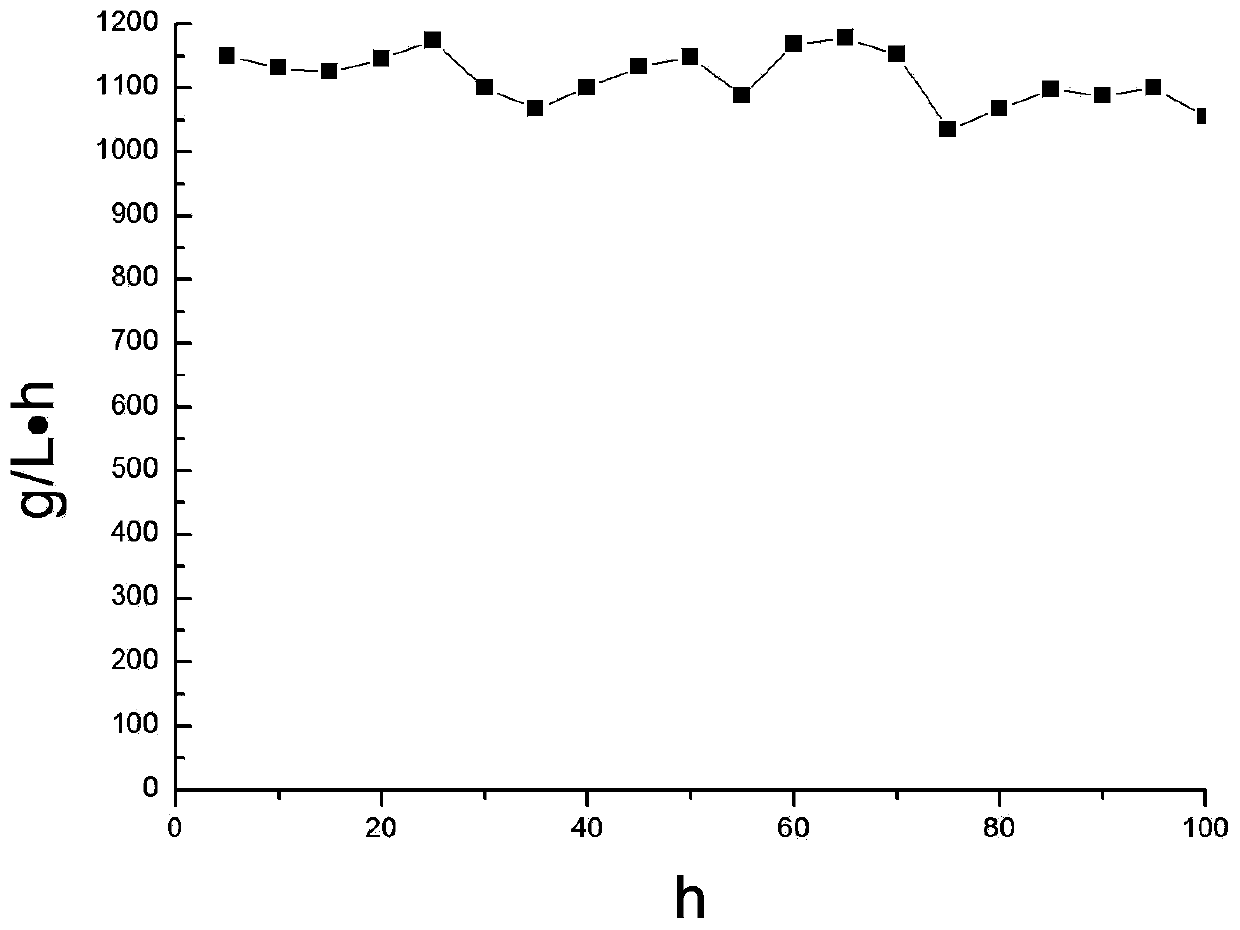

[0050] The B3 catalyst has been tested for 100h of life, and the activity is shown in figure 1 .

[0051] Sample Characterization:

[0052] Images via TEM (see Figure 2~3 ) and dispersion data (see table below), it can be seen that an appropriate amount of sodium borohydride concentration contributes to a substantial increase in dispersion, but as the concentration of sodium borohydride increases, the active components in the catalyst are reduced too quickly , the reunion grows up, and the dispersion decreases on the contrary.

[0053] sample name Metal Dispersion(%) Crystallite Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com