Aluminium silicate fibers and preparation method thereof

A technology for aluminum silicate fibers and products, applied in the field of aluminum silicate fibers and their preparation, can solve the problems of reduced production capacity and reduced natural resources, and achieves the effects of low cost and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A preparation method of aluminum silicate fiber, comprising the following steps:

[0022] The slag clinker and mineral clinker are melted and fiberized to obtain aluminum silicate fiber;

[0023] The mineral is selected from one or more of coal gangue, burnt gem and kaolinite.

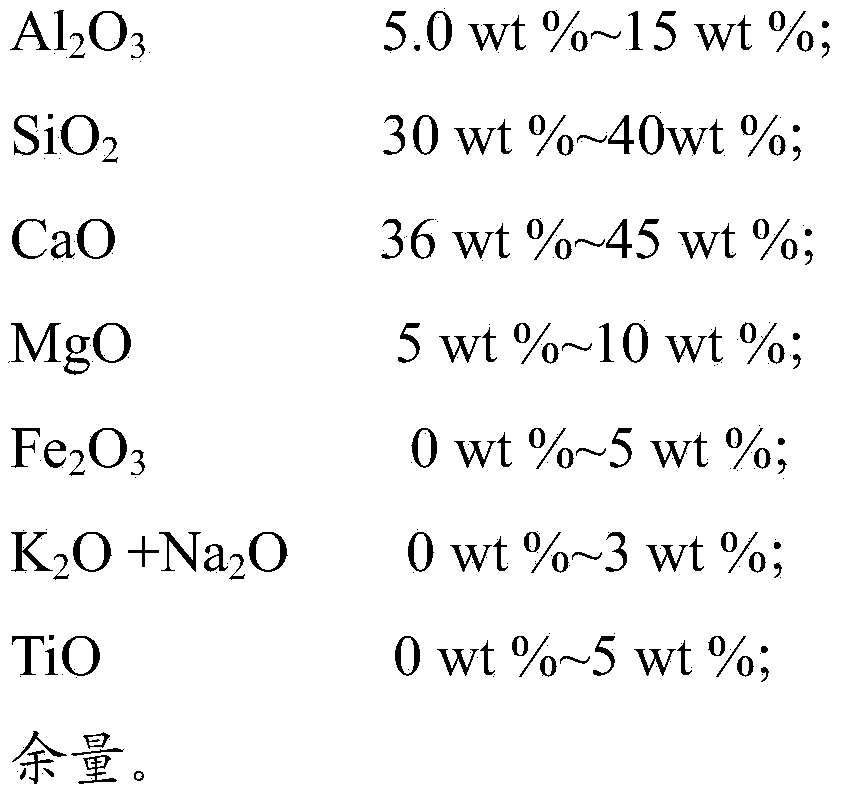

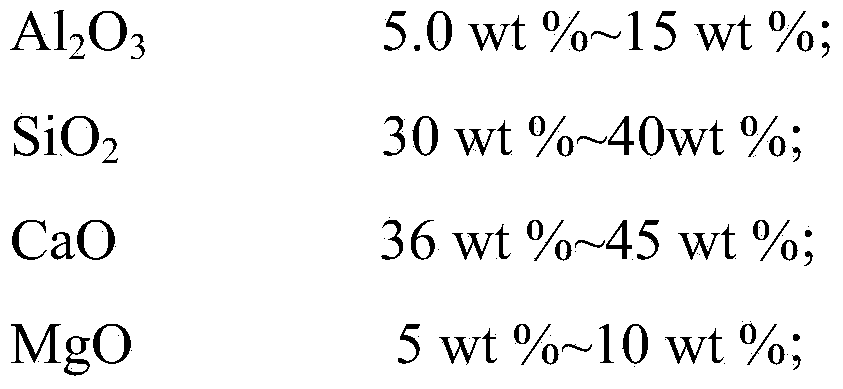

[0024] In the present invention, water slag clinker and mineral clinker are first melted. In the present invention, the source of the water slag clinker is not limited, and the water slag clinker known to those skilled in the art will suffice. Water slag is the process of rapidly cooling blast furnace slag in hot melt state in water. There are mainly two methods: water quenching in slag pool or water quenching in front of furnace. The present invention does not limit the components and sources of the water slag clinker, and conventional industrial wastes can be used. Preferably, the water slag clinker consists of the following components:

[0025]

[0026] margin.

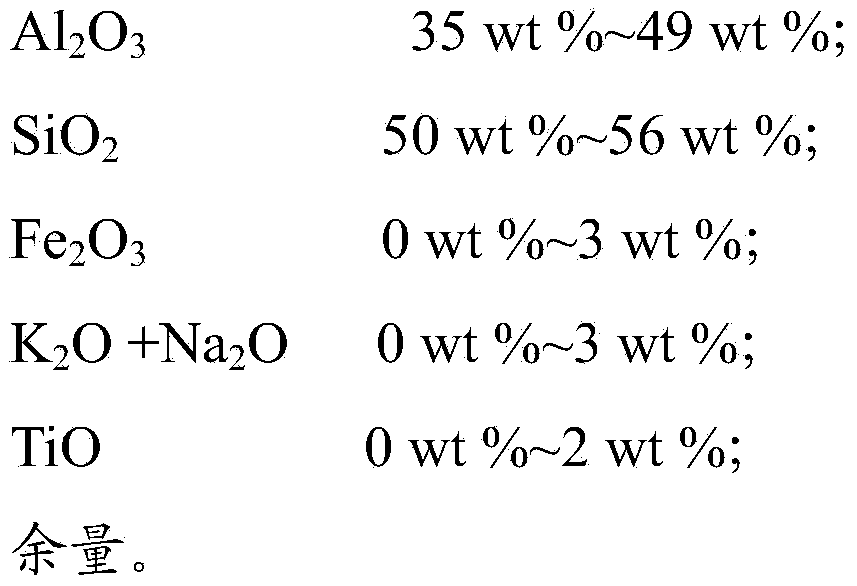

[0027] The mineral cl...

Embodiment 1

[0052] Composition of 20% by mass as Al 2 o 3 5.0%, SiO 2 30wt%, CaO36wt%, MgO5wt%, Fe 2 o 3 、K 2 O, Na 2 O, TiO mass percent total 2 o 3 35%, SiO 2 50wt%, Fe 2 o 3 、K 2 O, Na 2 Coal gangue clinker with a total mass percentage of O and TiO 2 o 3 34.20%, SiO 2 40.05%, CaO5.81wt%, MgO2.01wt%, the total mass percentage of other components <10%. The fiber cotton has a diameter of 1 μm to 6 μm, a fiber length of 5 mm to 100 mm, and a slag ball content of 16%.

Embodiment 2

[0054] Composition of 30% by mass as Al 2 o 3 10.0%, SiO 2 35wt%, CaO40wt%, MgO8wt%, Fe 2 o 3 、K 2 O, Na 2 O, TiO mass percent total 2 o 3 40%, SiO 2 53wt%, Fe 2 o 3 、K 2 O, Na 2 Coal gangue clinker with a total mass percentage of O and TiO 2 o 3 34.20%, SiO 2 40.05%, CaO5.81wt%, MgO2.01wt%, the total mass percentage of other components <10%. The fiber diameter is 2 μm to 5 μm, the fiber length is 30 mm to 60 mm, and the pellet content is 14%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Fiber average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com